Micro light emitting diode quantum dot display repair structure

A technology of micro-light-emitting diodes and quantum dots, which is applied in the field of repairing structures, can solve problems such as not being cost-effective and not cheap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

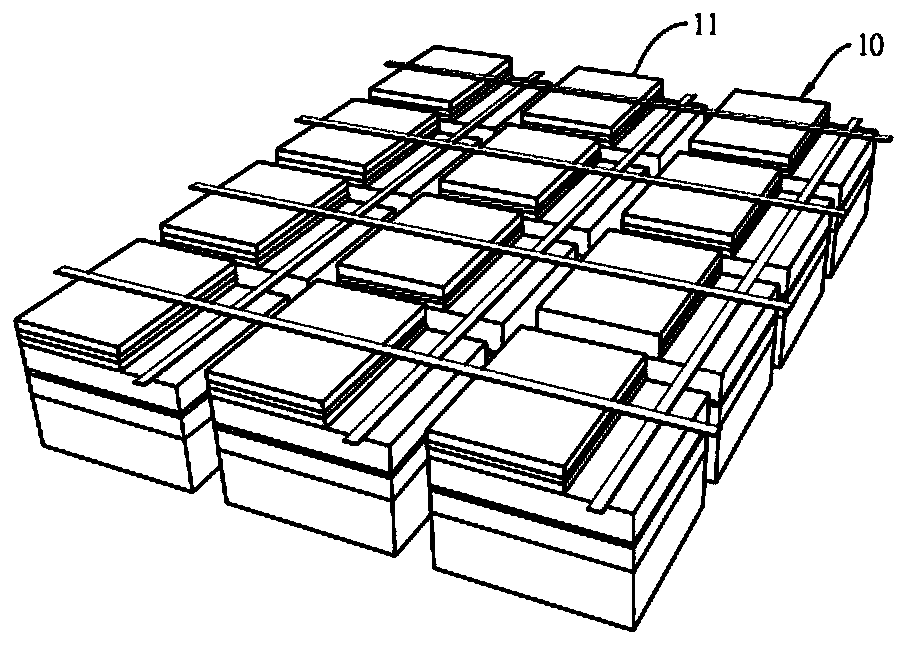

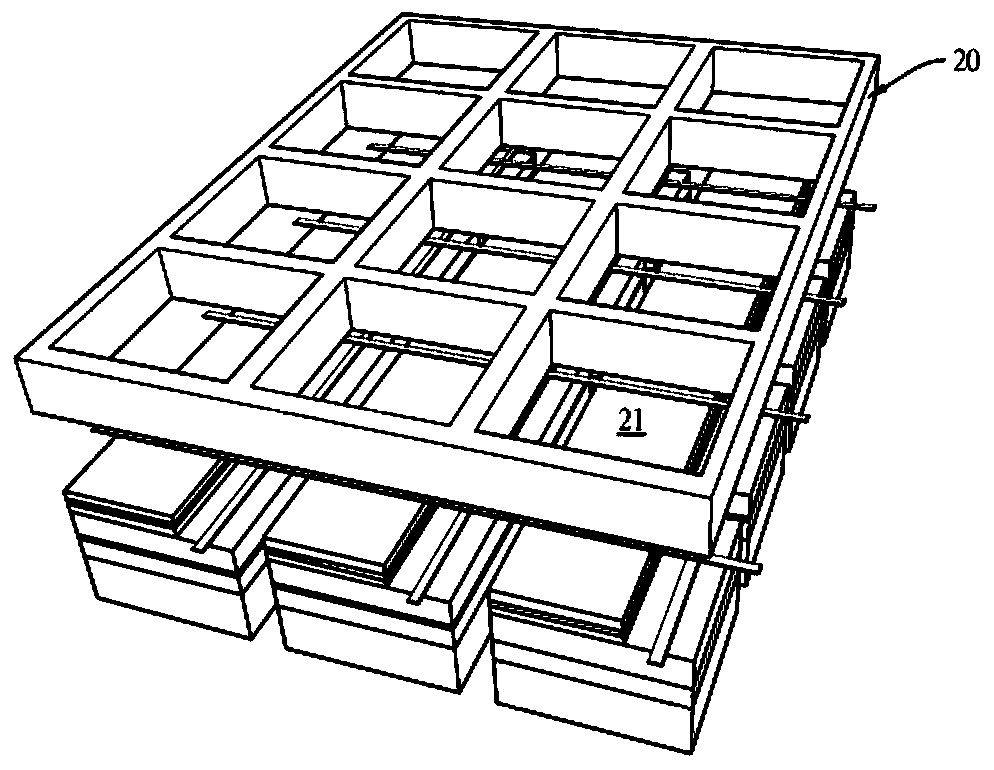

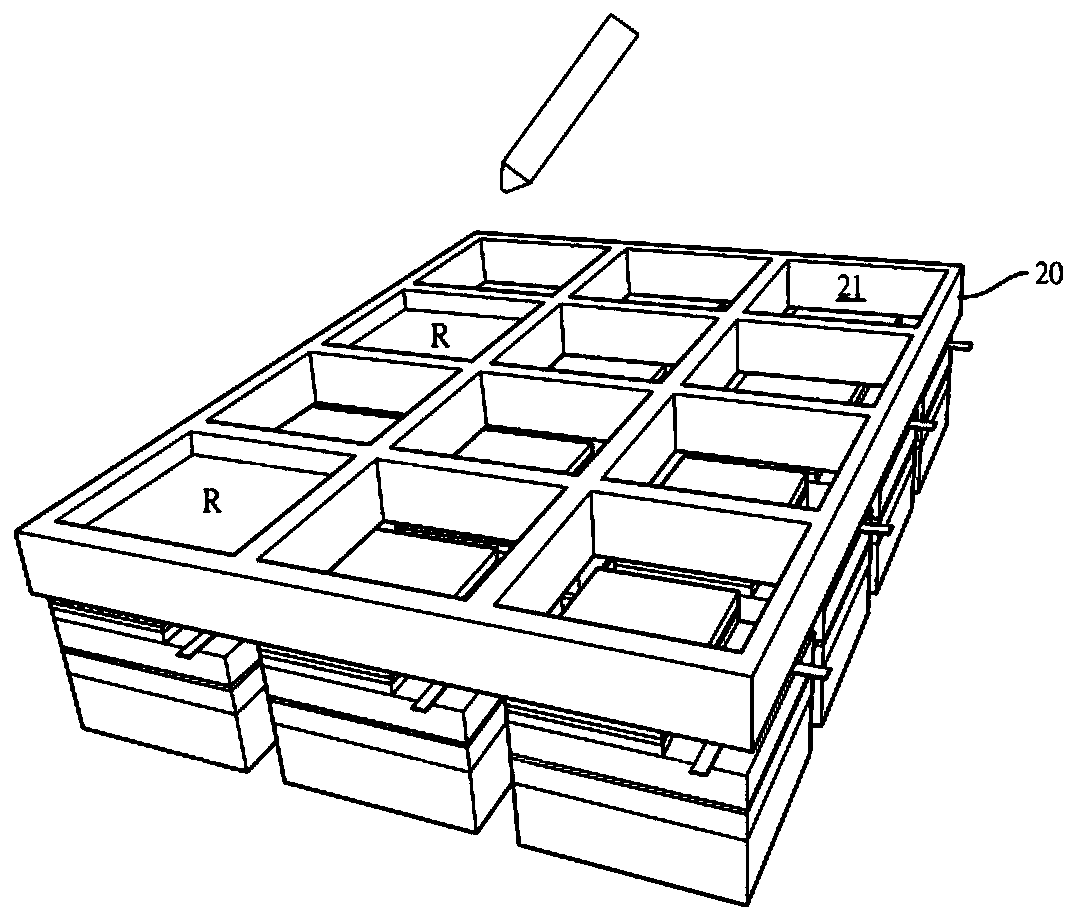

[0041] The present invention mainly relates to a micro-light-emitting diode quantum-dot display screen, in particular, a repair structure for a micro-light-emitting diode quantum-dot display screen with vacant quantum dots. As mentioned above, the current quantum dot display technology is gradually maturing. Since it is superior to the current liquid crystal display in terms of luminous height and resolution, the era of it as a replacement for the current liquid crystal display is just around the corner. Since the micro-light-emitting diode quantum dot display has the characteristics of a plurality of quantum dots, and each quantum dot also has fluorescent powder independent of other quantum dots, it provides the user with a fluorescent powder in at least one When the filled quantum dots fail, there is a chance to repair the faulty display screen.

[0042] The main purpose of the present invention is to provide a repair structure of a micro-light-emitting diode quantum dot dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com