Intelligent inspection robot control system and method based on high voltage transmission line

A technology for high-voltage transmission lines and line inspection robots, applied in the field of robots, can solve the problems of difficult operation, increased investment in costs, low line inspection efficiency, etc., and achieve the effects of reducing economic losses, improving reliability and improving economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

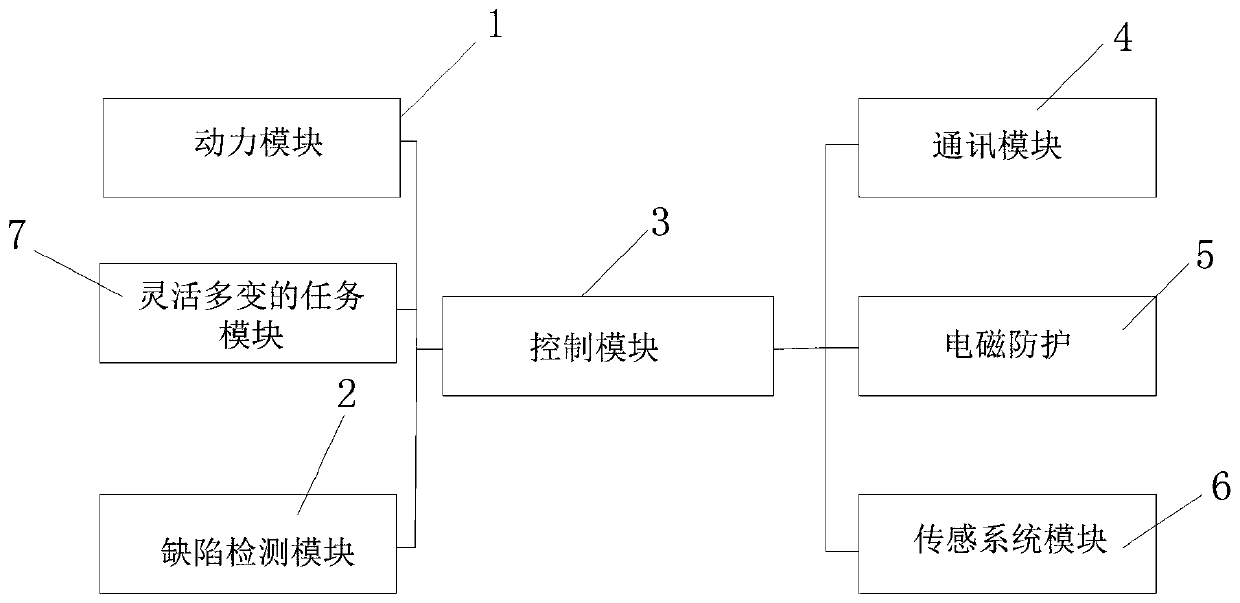

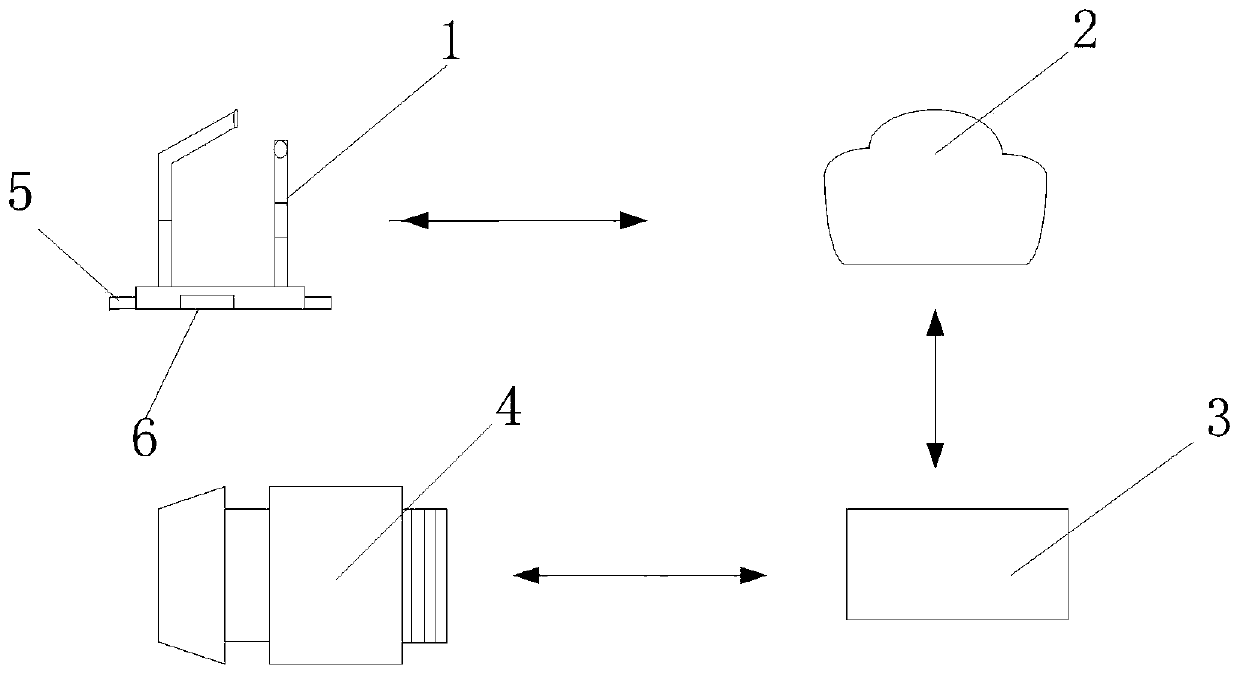

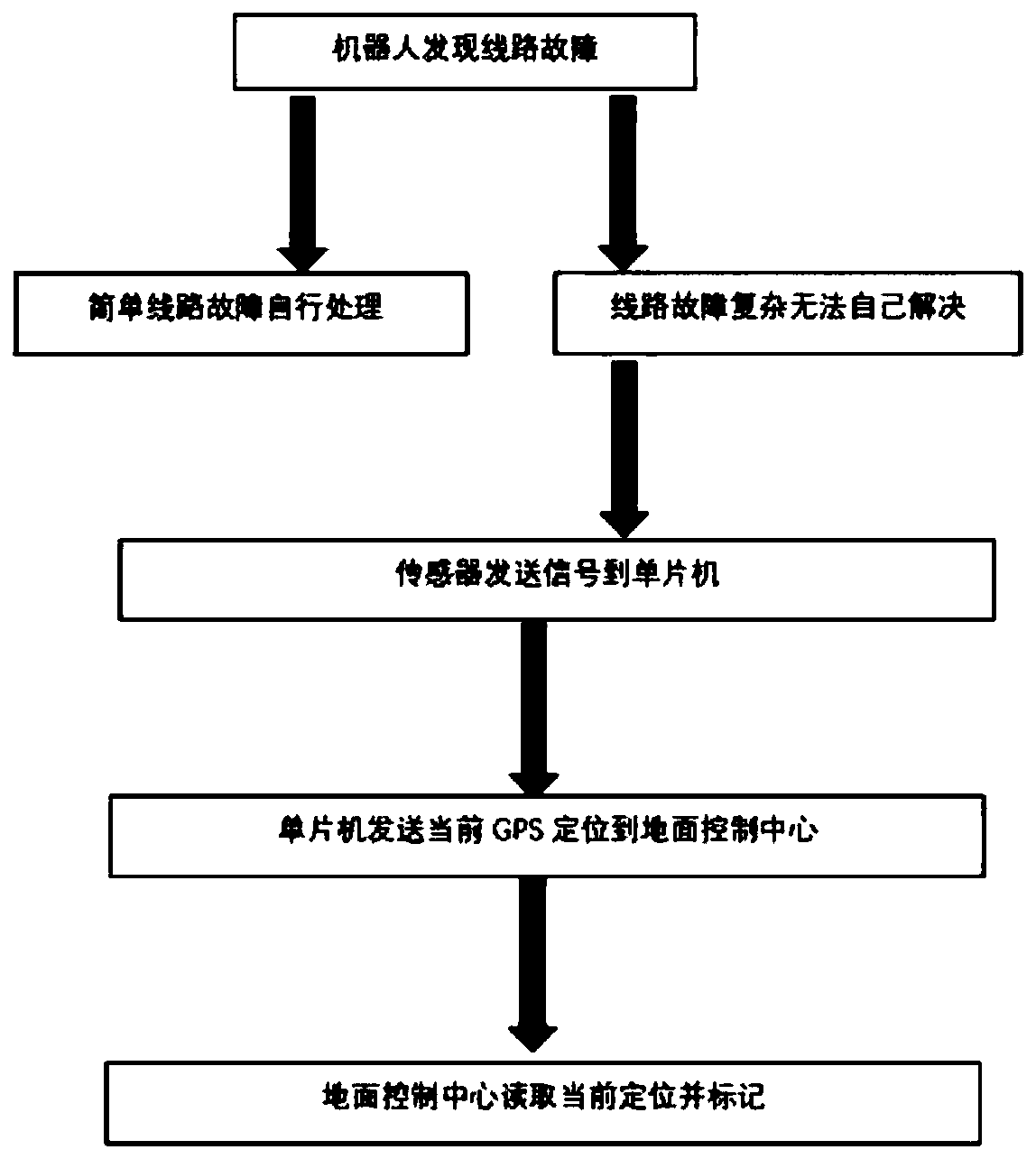

Method used

Image

Examples

Embodiment 1

[0053] Controller Selection

[0054] K60N512VM100 chip power supply pins, BGA package 22, LQFP package 27, of which five pins of the BGA package chip are not used (A10, B10, C10, M5 and L5). The chip uses multiple sets of power supply pins to supply power to the internal voltage regulator, I / O pin driver, A / D conversion circuit and other circuits, and the internal voltage regulator supplies power to the core and oscillator. In order to stabilize the power supply, the MCU contains multiple sets of power supply circuits, and provides multiple power supply pins at the same time, which is convenient for external filter capacitors. In order to balance the power supply, the MCU provides multiple pins of internally connected grounds for use in circuit design.

[0055] K60N512VM100 chip pin function table, as follows:

[0056]

Embodiment 2

[0058] The drive circuit L298N drive module sends control signals to the drive module through the controller, and then determines the movement mode and speed of the robot.

Embodiment 3

[0060] Thermal faults can be instantly revealed through the infrared camera. It is non-contact and away from the detected equipment, ensuring the safety of personnel and does not affect the original operating status of the equipment; it can directly display the thermal distribution of the equipment in the form of images; automatically capture the highest, low temperature, and display The specific position and temperature value can be displayed; large-area rapid scanning detection saves time; the temperature measurement range is wide and the accuracy is high.

[0061] During the electrical discharge of high-voltage equipment, corona, flashover or arc will occur depending on the strength of the electric field. Electrons in the air are constantly gaining and releasing energy, and when the electrons release energy (i.e. discharge), they emit ultraviolet light. Ultraviolet imaging technology uses this principle to receive the ultraviolet signal generated when the equipment discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com