Fe-Mn porous alloy material and preparation method and application thereof

An alloy material, fe-mn technology, applied in the field of biomedicine, can solve the problems of human body's natural bone mismatch, stress shielding, high elastic modulus, etc., and achieve the effect of short experiment period, low cost and uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

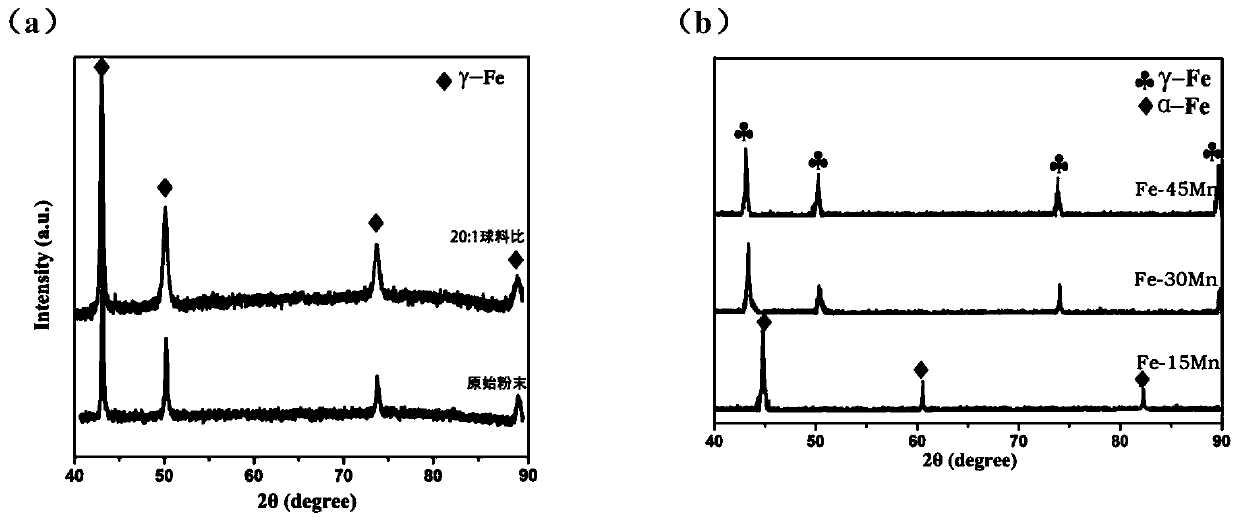

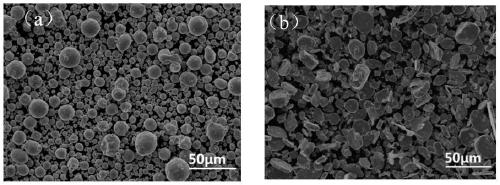

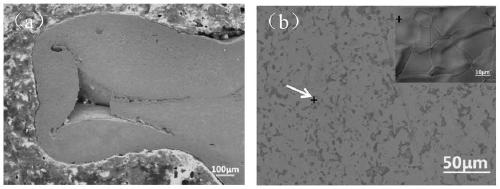

Embodiment 1

[0052] First, 15ppi polyurethane sponge (pore size 0.7 ~ 1mm, density 24kg m -3 ) soaked in the NaOH solution whose concentration of the substance is 1mol / L to remove impurities and coarsen, take out room temperature and air-dry for subsequent use; subsequently, measure 6wt.%PVA, 0.1wt.%CMC, and the balance is deionized water and Silica sol (deionized water: silica sol=3:1) is prepared into a mother liquor with a certain viscosity and the pH value is adjusted to 8. This process is carried out in a constant temperature water bath at 100°C; the atomized FeMn alloy powder (mass fraction: Fe47% , Mn 53%, particle size is 25~30μm) to carry out ball milling, and wherein ball material ratio is 20:1, and ball milling speed is 300rpm, mixes with mother liquor after ball milling 5h, and solid-liquid mass ratio is 1:0.5, waits to mix evenly and sponge Immerse in the slurry and extrude to remove excess slurry to form a sponge-slurry complex; after drying and degreasing at 350°C, a degreas...

Embodiment 2

[0068] First, 15ppi polyurethane sponge (pore size 0.7 ~ 1mm, density 24kg m -3 ) soaked in the NaOH solution whose concentration of the substance is 1mol / L to remove impurities and coarsen, take out room temperature and air-dry for subsequent use; subsequently, measure 8wt.%PVA, 0.15wt.%CMC, and the balance is deionized water and Silica sol (deionized water: silica sol=3.5:1) is prepared into a mother liquor with a certain viscosity and the pH value is adjusted to 8. This process is carried out in a constant temperature water bath at 100°C; the atomized FeMn alloy powder (mass fraction: Fe55% , Mn 45%, particle size is 20 ~ 25 μm) for ball milling, wherein the ball-to-material ratio is 20:1, the ball milling speed is 300rpm, the time is 8h, the solid-liquid mass ratio is controlled at 1:0.5, and the sponge is immersed in the Slurry and extruded to form a sponge slurry complex after removing excess slurry; after drying and degreasing at 350°C, a degreased body is formed, and a...

Embodiment 3

[0081] First, 20ppi polyurethane sponge (pore size 0.3 ~ 0.7mm, density 28kg m -3 ) soaked in the NaOH solution whose concentration is 1mol / L to remove impurities and coarsen, take out room temperature and air-dry for subsequent use; subsequently, measure 10wt.%PVA, 0.32wt.%CMC, and the balance is deionized water and Silica sol (deionized water: silica sol = 4:1) is prepared into a mother liquor with a certain viscosity and the pH value is adjusted to 8.2. This process is carried out in a constant temperature water bath at 100°C; the atomized FeMn alloy powder (mass fraction: Fe 55 %, Mn 45%, particle size 15-20μm) for ball milling, wherein the ball-to-material ratio is 30:1, the ball milling speed is 275rpm, the time is 8h, and the solid-liquid ratio is controlled at 1:0.45. After mixing evenly, immerse the sponge in the slurry and squeeze it to remove excess slurry to form a sponge-slurry complex; after drying and degreasing at 350°C, a degreased body is formed, and argon ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap