Novel crushing chamber

A crushing bin, a new type of technology, applied in the field of machinery, can solve the problems of long cycle, energy waste, insufficient absorption of nutrients, etc., and achieve the effect of adjustable crushing force, good crushing effect and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

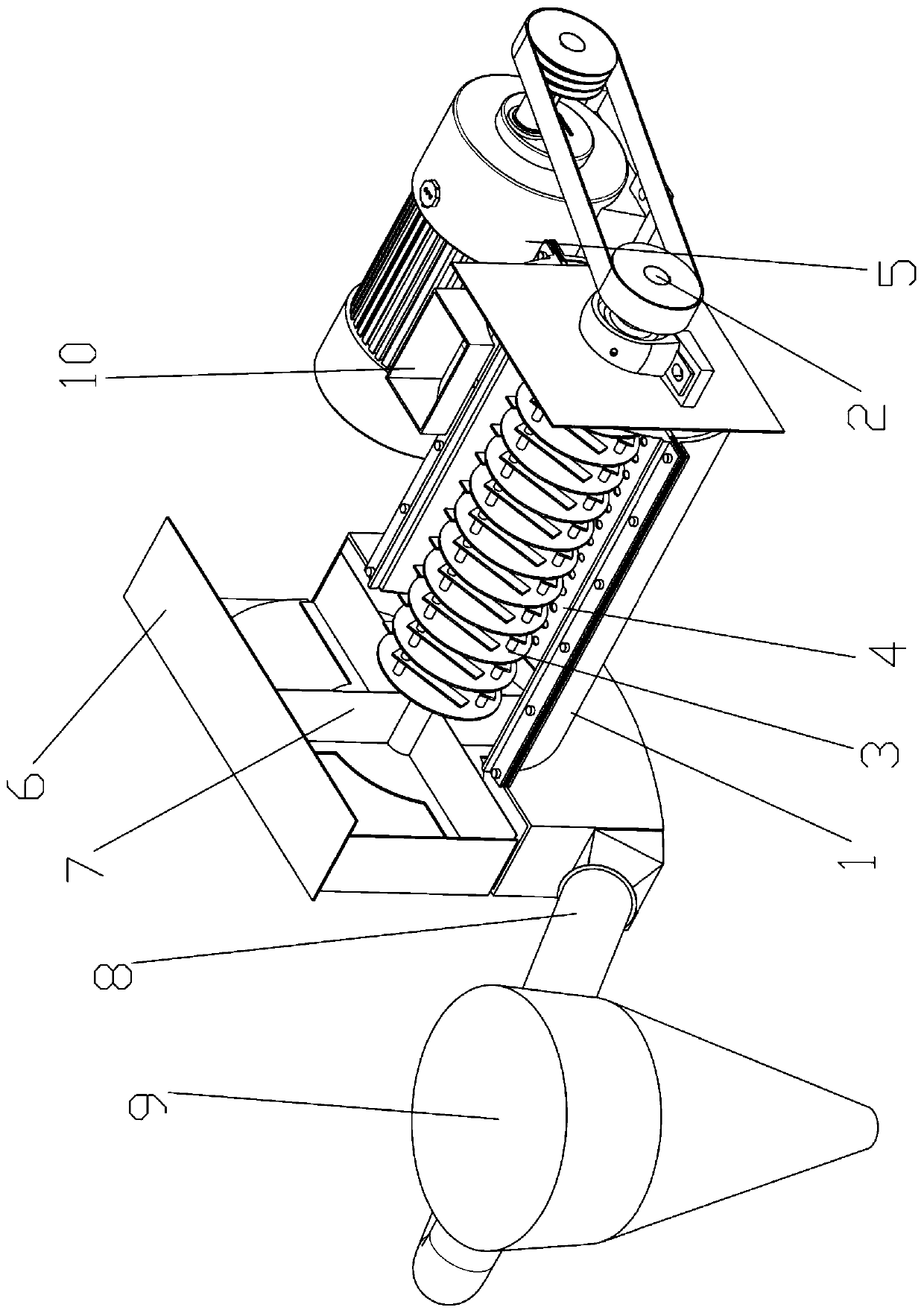

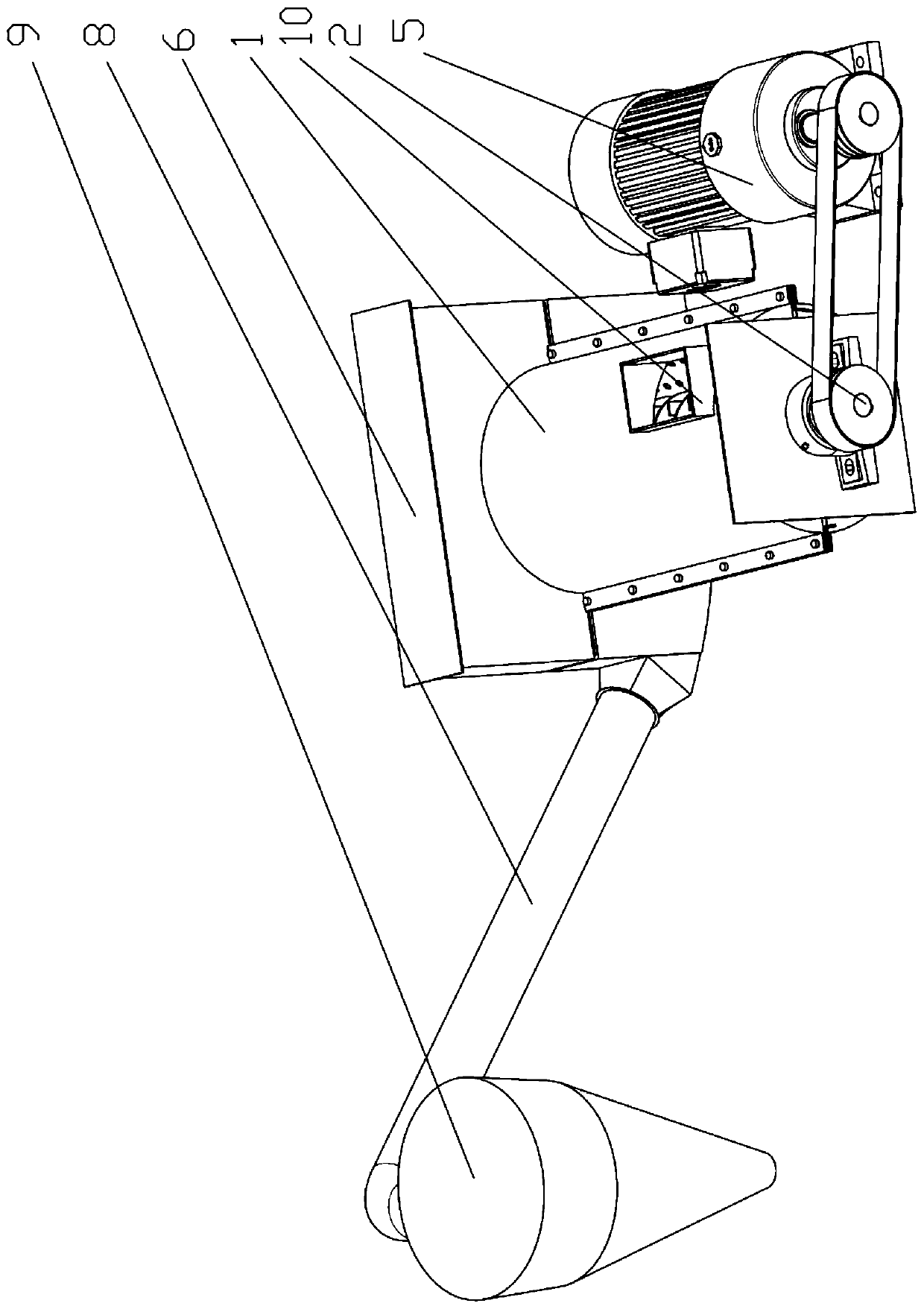

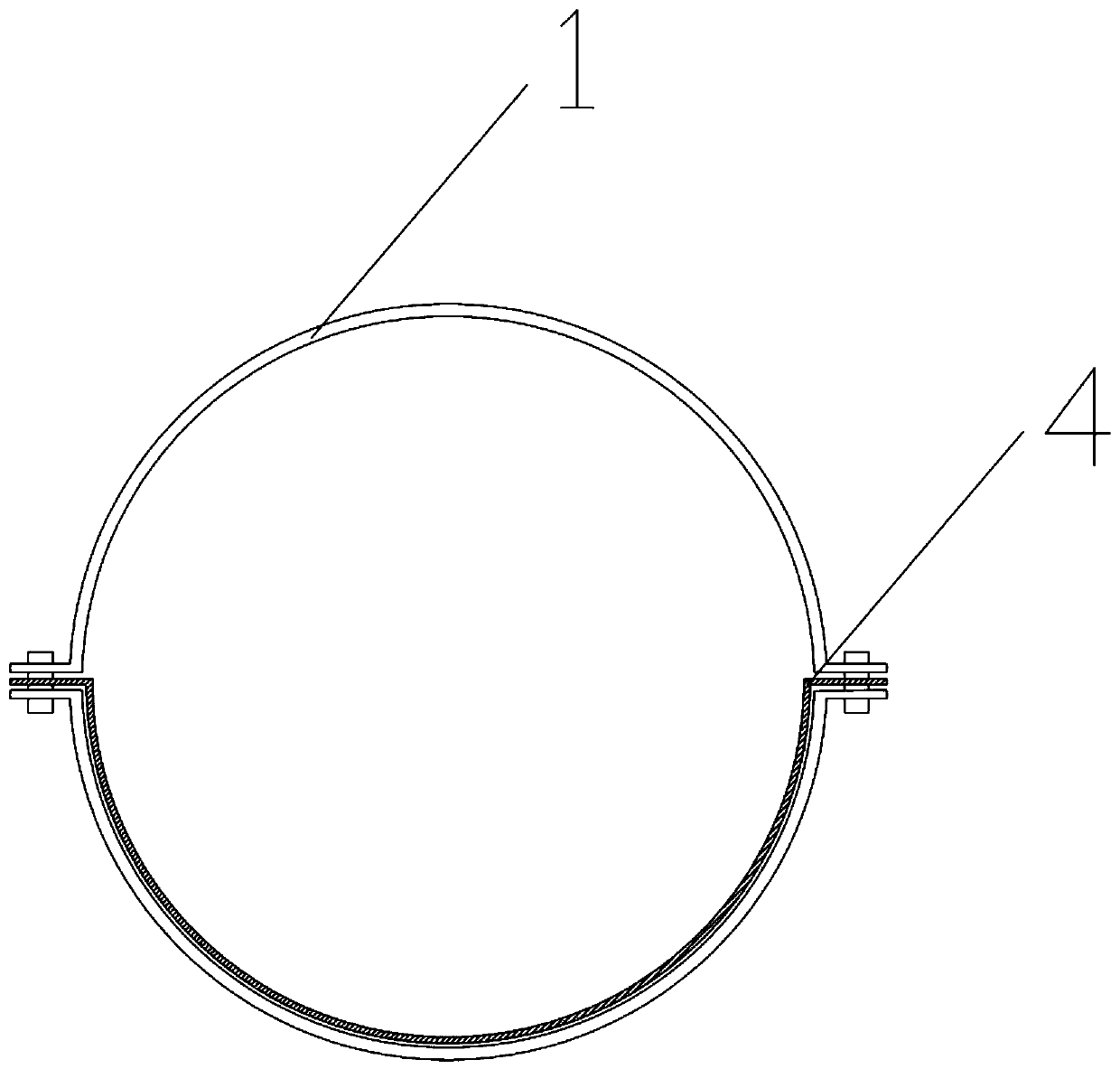

[0025] Example: such as Figure 1-4 As shown, a new type of crushing bin includes crushing bin 1, spindle 2, hammer knife 3, motor 5, conveying pipe 8 and feed inlet 10, wherein: crushing bin 1 is a cylindrical bin; crushing bin 1 is fixedly connected There is a main shaft 2; the main shaft 2 is concentric with the central axis of the crushing chamber 1; the main shaft 2 is provided with several hammer cutters 3; the main shaft 2 and the motor 5 are connected by pulleys and belts; one side of the crushing chamber 1 is sealed, and the other side It is fixedly connected with the wind bin 6; the fan 7 is arranged in the wind bin 6; the outlet of the wind bin 6 is connected with the conveying pipe 8; the outlet of the conveying pipe 8 is connected with the material hopper 9; a screen is arranged under the main shaft 2 and the hammer knife 3 Bottom 4; The screen bottom 4 is a semi-cylindrical body; the screen bottom 4 is movably connected to the crushing chamber 1, and the minimum d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap