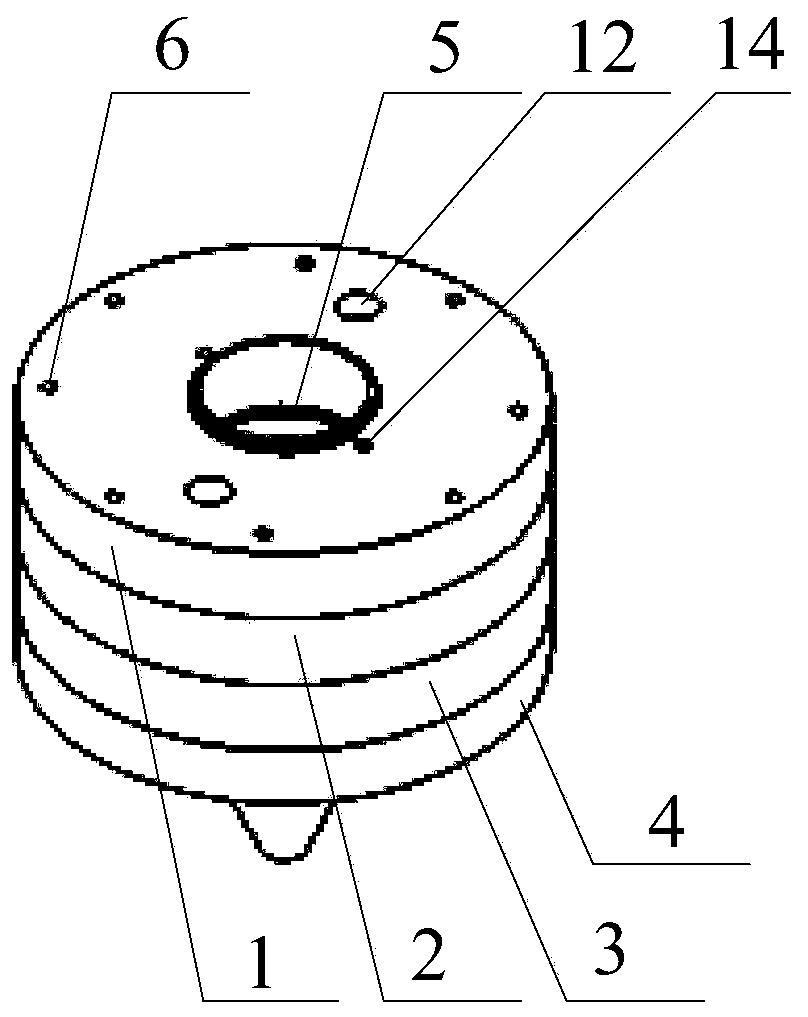

Powder feeding head for underwater laser additive manufacturing and cladding layer preparation

A technology of additive manufacturing and underwater laser, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. The time of action, the effect of improving the utilization rate of powder and improving the effect of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

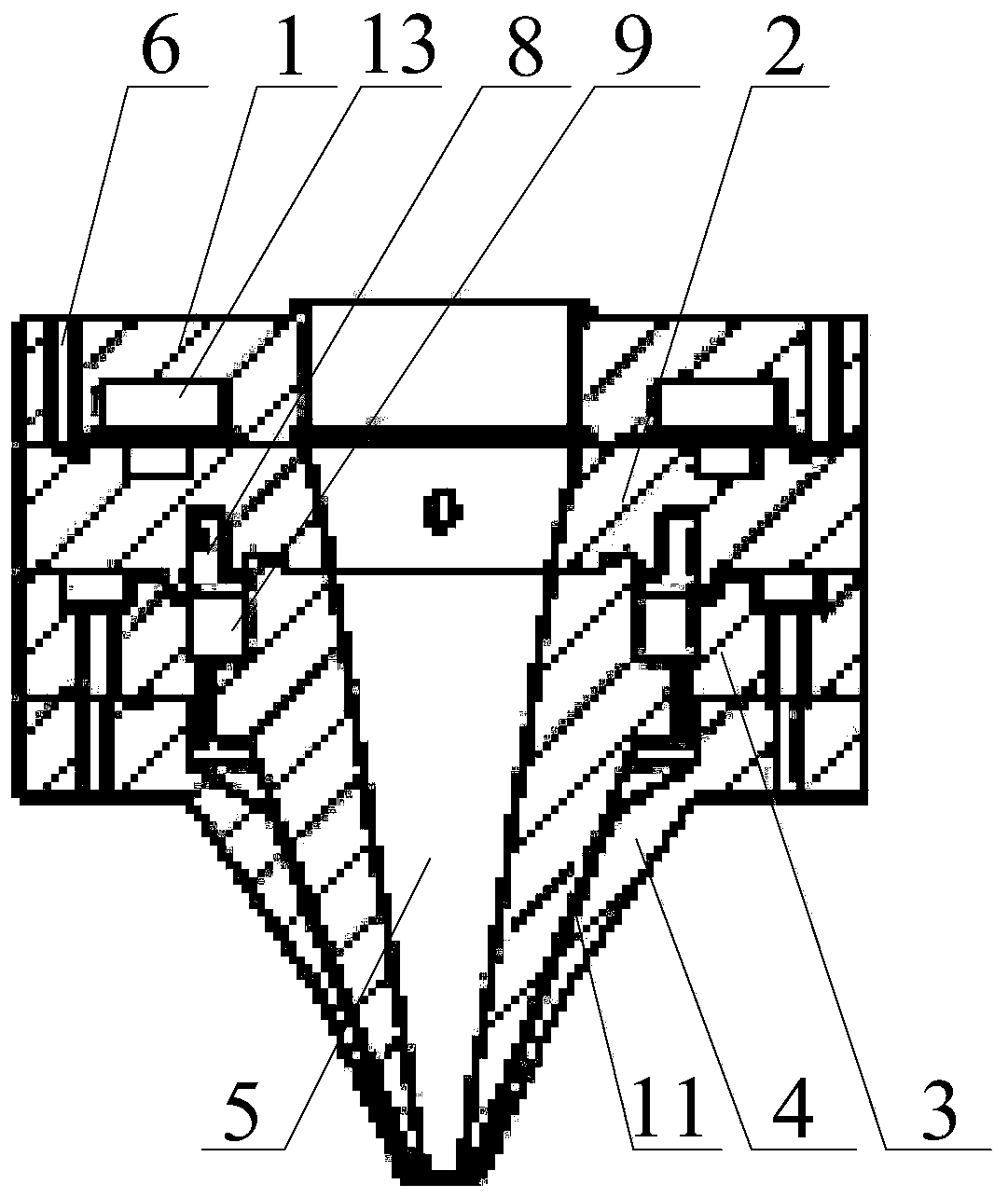

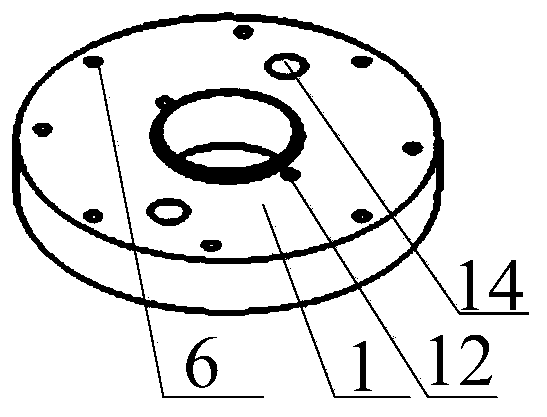

[0049] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] Some of the existing laser powder feeding heads use multi-needle coaxial powder feeding, and some use sideways powder feeding.

[0051] The inventor found through analysis that for laser cladding with lateral powder feeding, due to the long powder travel path, the powder has poor convergence to the deposition point, and the overall equipment assembly degree is high, it is not suitable for underwater laser additive manufacturing. At the same time, the protective atmosphere only protects the part of the substrate. In the absence of mechanical protection measures, an excessive protective atmosphere flow rate will seriously damage the powder path and damage the deposition point. From the perspective of laser additive manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com