Low-density veneer oriented strand board

A technology of oriented particle board and low density, applied in the field of particle board, can solve the problems of high production cost, long production cycle and high price of board, and achieve the effect of good processing performance, smooth hand feeling and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

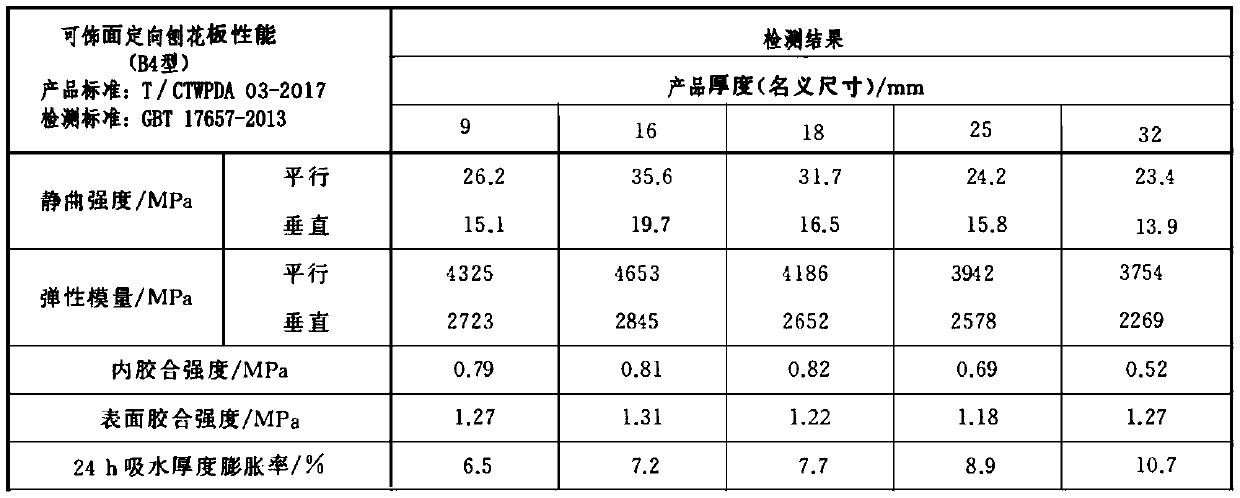

[0024] A low-density decorative oriented strand board, comprising a core layer, a subsurface layer and a surface layer, the core layer particles are arranged horizontally, and the subsurface layer particles are arranged vertically, which is an OSB three-layer structure;

[0025] Described preparation process comprises the following steps:

[0026] (1) Preparation of shavings

[0027] The raw materials for the surface layer are scraps, sawdust, and shavings produced in the production process of plywood, blockboard, and particle board; the above raw materials are crushed into fibers by the latest pulse-type airflow crusher developed by the German Siempelkamp Group; the subsurface layer, the core The raw material of the layer is the small-diameter wood and branch wood produced by fast-growing poplar harvesting. After peeling, the small-diameter wood is sliced into shavings with a length of 120mm, a width of 25-50mm, and a thickness of about 0.6mm. After peeling, the branch wood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com