Preparation method of porous nano spherical zinc-cadmium sulfide solid solution

A technology of zinc cadmium sulfide and solid solution, which is applied in the field of photocatalytic materials, can solve the problems of low photocatalytic hydrogen production performance, high cost, and complicated preparation process, and achieve excellent promotion and application prospects and high-efficiency photocatalytic hydrogen production performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of porous nano-spherical zinc cadmium sulfide solid solution, comprising the following steps:

[0027] Step 1. Weigh Zn(Ac) according to the molar ratio of 0.8 to 1:1 2 2H 2 O, Cd(Ac) 2 2H 2 O is dissolved in the mixed solution of ethylene glycol and sodium hydroxide, and vigorously stirred at a speed of 600-800rpm for 1-3 hours; wherein, the concentration of sodium hydroxide in the mixed solution of ethylene glycol and sodium hydroxide is 0.08-0.12 mol L -1 ;

[0028] Step 2, add according to the following molar ratio: thiourea: Zn(Ac) 2 2H 2 O: Cd(Ac) 2 2H 2 O=4~5:1:1, add thiourea to the solution prepared in step 1, continue to stir at a speed of 800~1000rpm for 30~60min, and then continue to react at a reaction temperature of 160~180°C for 24~48h After the reaction, cool to room temperature to obtain a crude product, wash the crude product repeatedly with deionized water and absolute ethanol, centrifuge and recover the product, and vacu...

Embodiment 1

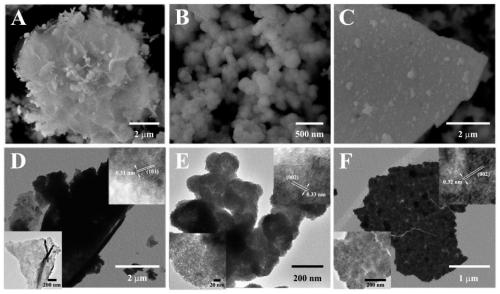

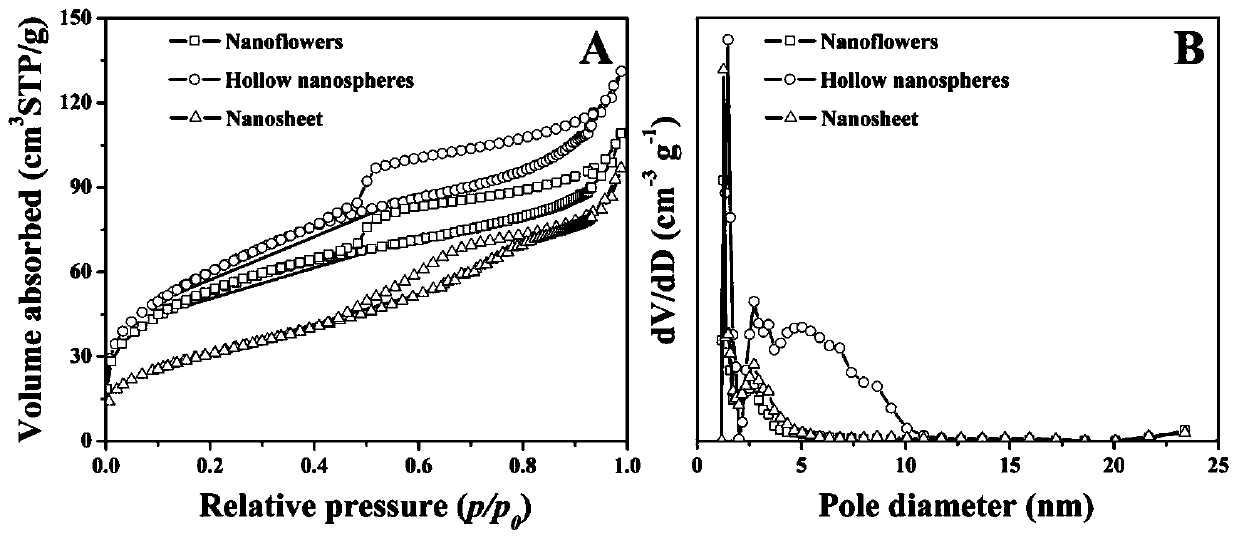

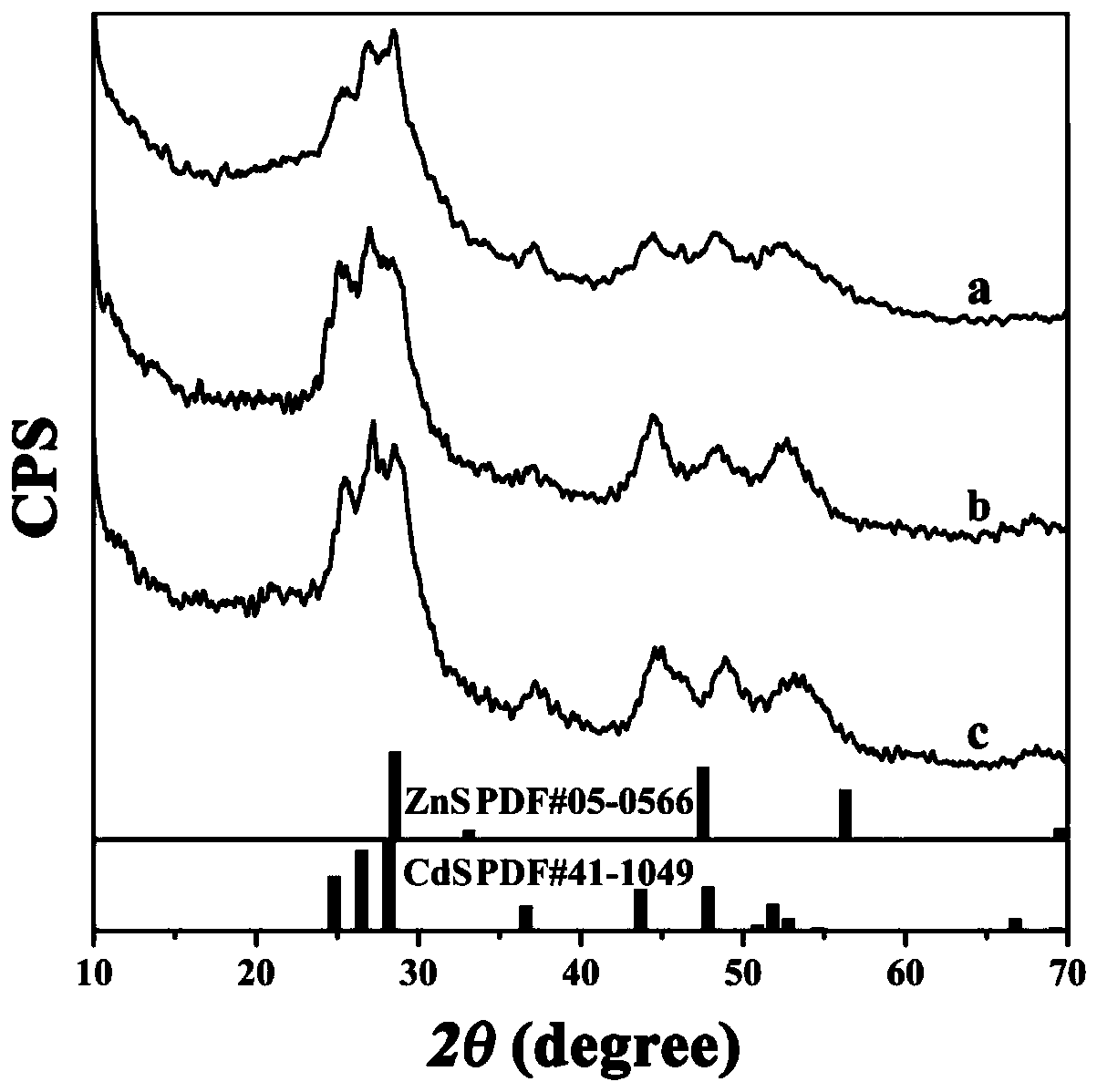

[0030] (1) Example 1: Preparation of porous nano-spherical zinc cadmium sulfide solid solution

[0031] 0.5mmoL Zn(Ac) 2 2H 2 O and 0.5mmol Cd(Ac) 2 2H 2 O dissolved in 10mL 0.1mol L -1 In the mixed solution of sodium hydroxide and ethylene glycol, after stirring at room temperature for 2h at a speed of 800rpm, add 2mmoL thiourea (CN 2 h 4 S), and the sodium hydroxide and ethylene glycol solution were fixed to 35ml, and after the above-mentioned suspension was stirred at a speed of 1000rpm for 30min, the reaction was continued at 160°C for 24h, and the reaction was repeatedly cleared with deionized water and absolute ethanol The resulting crude product was centrifuged to recover the product, and dried in vacuum at 60° C. for 12 hours to prepare a porous nano-spherical zinc-cadmium sulfide solid solution.

Embodiment 2

[0032] (2) Example 2: Preparation of porous nano-spherical zinc cadmium sulfide solid solution

[0033]1mmoL Zn(Ac) 2 2H 2 O and 1mmoL Cd(Ac) 2 2H 2 O dissolved in 20mL 0.12mol L -1 In the mixed solution of sodium hydroxide and ethylene glycol, after stirring at room temperature for 3h at a speed of 700rpm, add 4mmoL thiourea (CN 2 h 4 S), continue to stir the above suspension at 900rpm for 45min, continue to react at 170°C for 36h, use deionized water and absolute ethanol to repeatedly clear the crude product generated by the reaction, then centrifuge to recover the product, and dry it in vacuum at 65°C 11h, the porous nano-spherical zinc-cadmium sulfide solid solution was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com