A processing method for compressor impeller of VTR series supercharger

A processing method and supercharger technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem that the sample ring cannot fully and truly reflect the parts, and achieve the effect of avoiding the internal stress of the clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

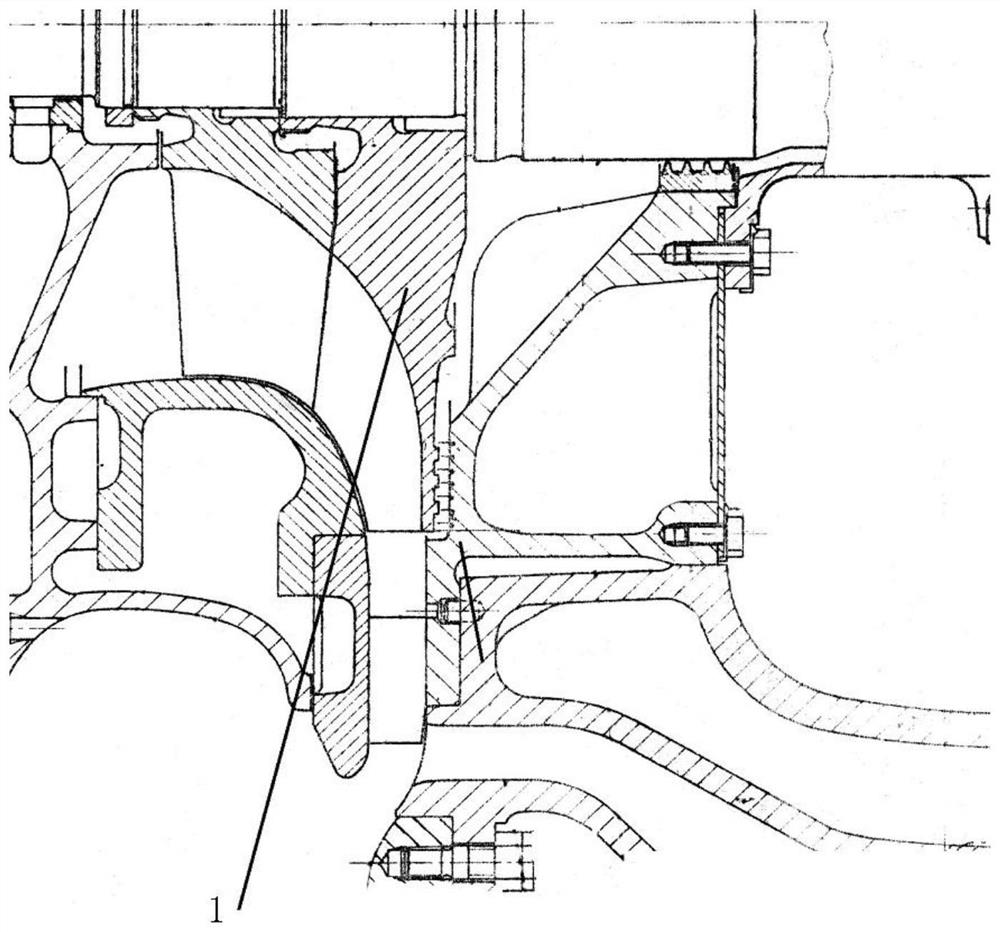

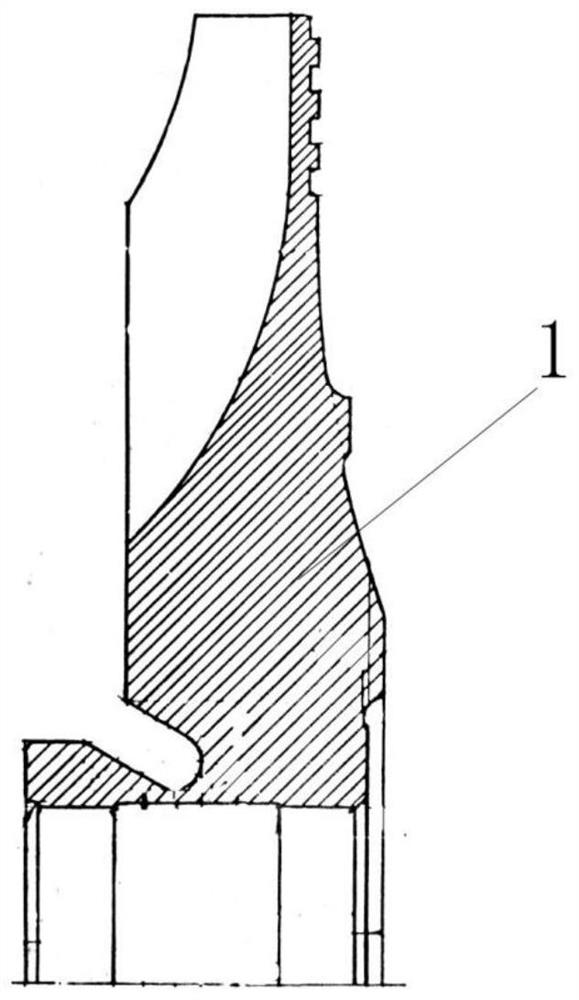

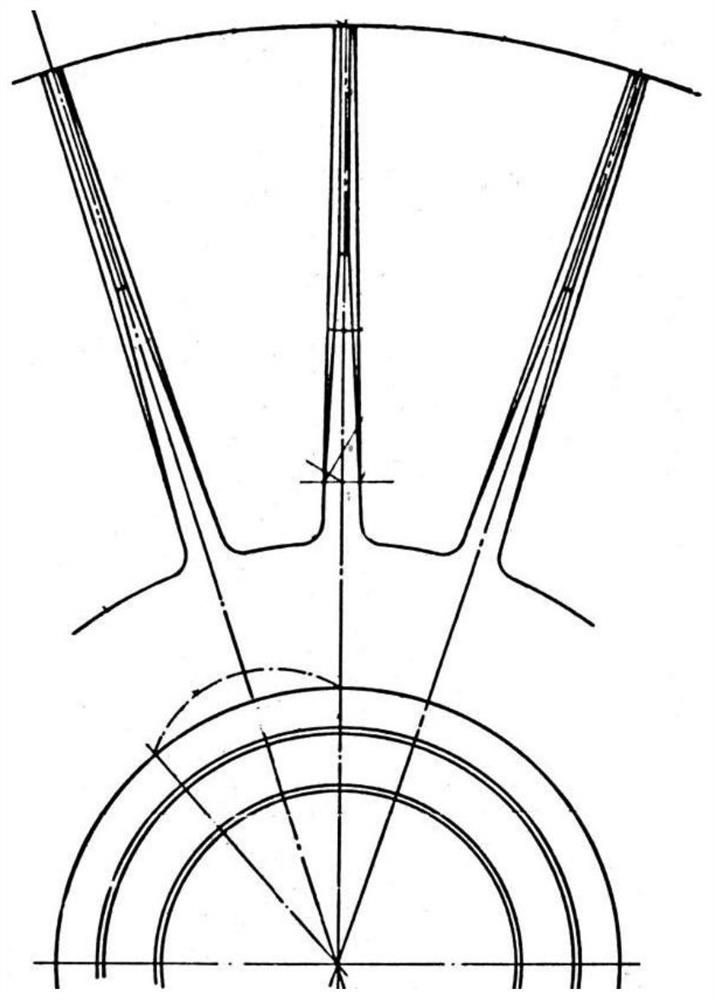

[0059] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0060] like Figure 15 , Figure 16 As shown, a turning tool for VTR series supercharger compressor impeller, including a base 301 and a clamping block 302 at one end of the base, the base 301 is vertically provided with a stepped hole fixedly connected to the machine tool chuck 4 3011, the turning tool 3 is fastened to the machine tool chuck 4 through a stepped hole with a screw, and the side of the clamping block 302 facing the base 301 is provided with an inner arc surface 3021 for clamping the large outer circle of the impeller. The tools 3 are uniformly arranged on the machine tool chuck, and move radially along the machine tool chuck 4 to clamp the impeller 1 .

[0061] like Figure 4 to Figure 14 As shown, a VTR series supercharger compressor impeller processing method includes the following steps:

[0062] a. Drill the axial inner h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com