Blind flange injection molding process mold and usage method thereof

An injection molding process and mold technology, which is applied in the field of flange cover injection molding process molds, can solve the problems of difficult demoulding, difficult ejection and demoulding, and large core wrapping force, so as to improve the injection molding production efficiency and product rate. , to ensure the minimum deformation, reduce the effect of demoulding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

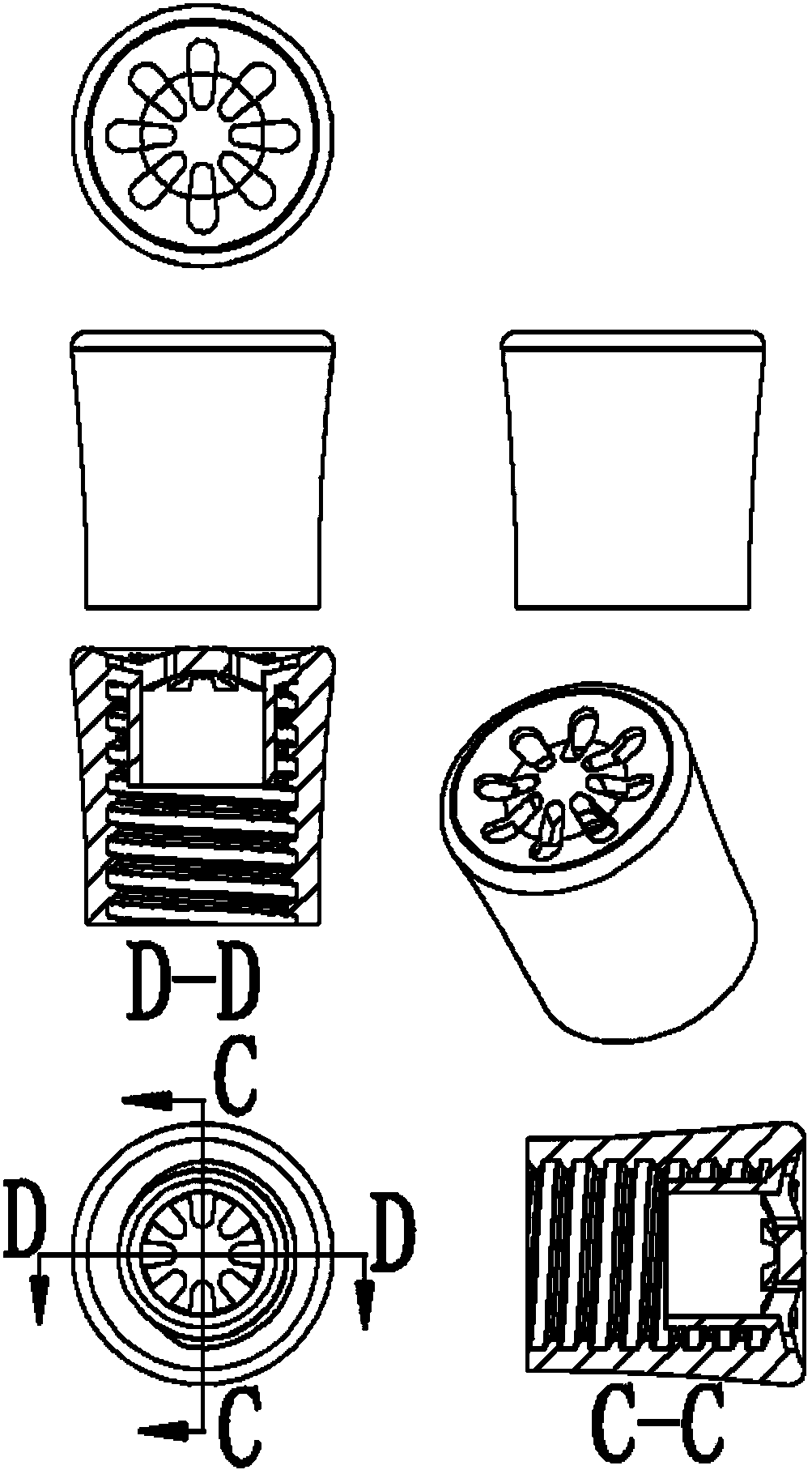

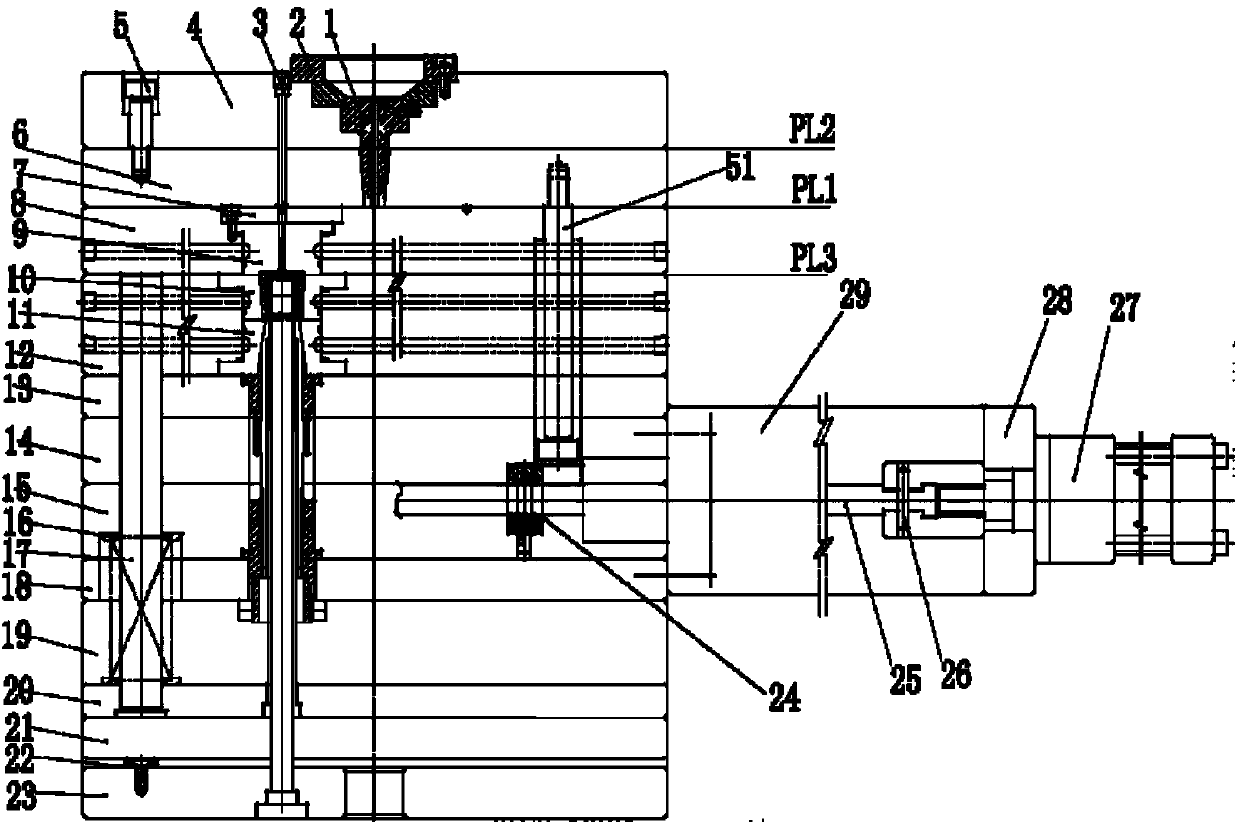

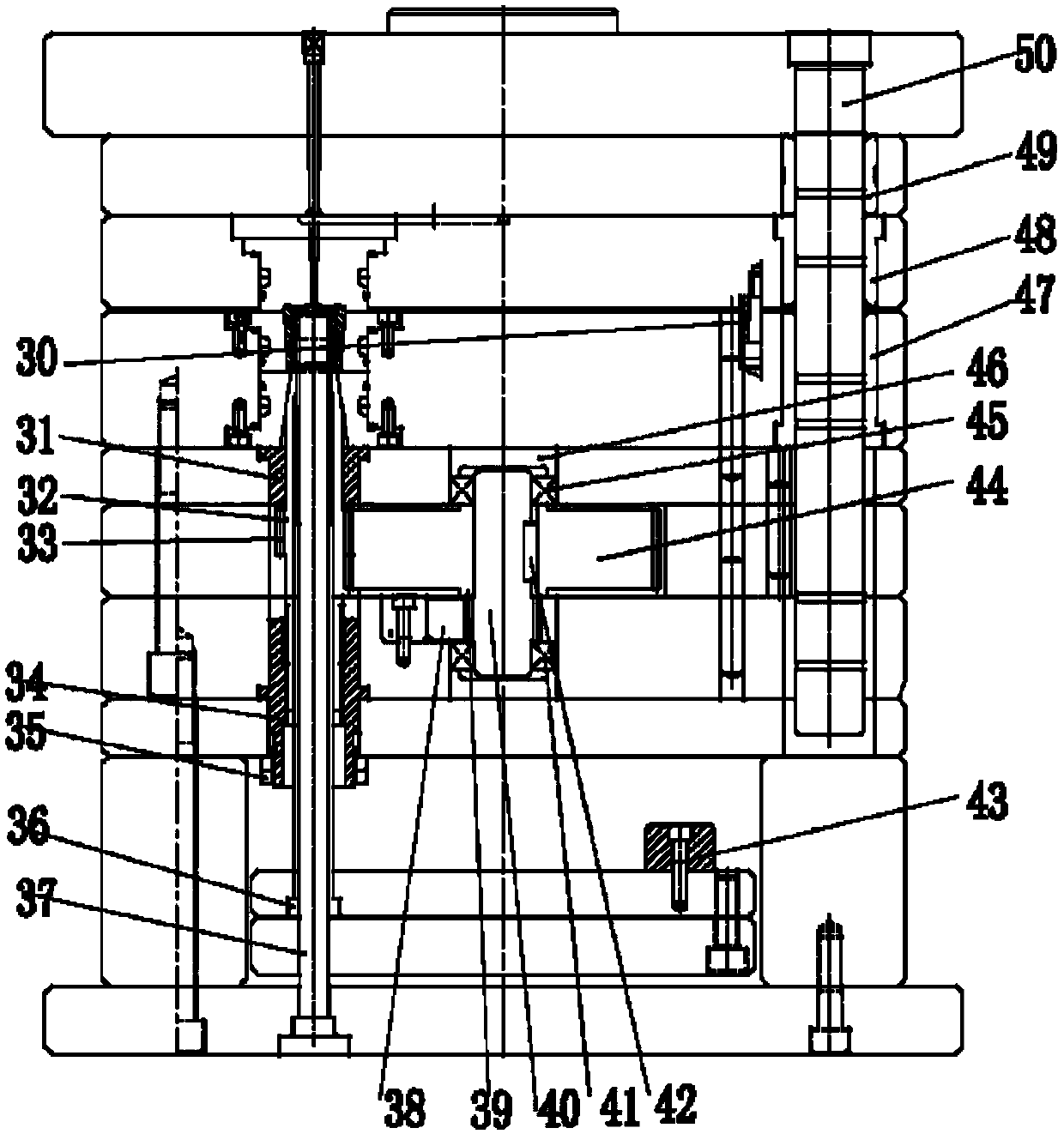

[0021] Figure 1-5 Shown is the relevant explanatory figure of the present invention; The specific embodiment is, as figure 2 , image 3 , Figure 4 , Figure 5 As shown, a flange cover injection molding process mold includes a sprue sleeve 1, a positioning ring 2, a front mold pull rod 3, a panel 4, a runner plate front tie rod 5, a runner plate 6, and a runner plate insert plate 7. Front template 8, front mold insert 9, rear mold upper insert 10, rear mold lower insert 11, movable template 12, first backing plate 13, second backing plate 14, third backing plate 15, reset lever Spring 16, reset lever 17, fourth backing plate 18, die foot 19, thimble cover plate 20, thimble push plate 21, garbage nail 22, bottom plate 23, rack guide block 24, rack pull rod 25, rack slider 26 , rack drive oil cylinder 27, oil cylinder mounting plate 28, rack slider base plate 29, resin switch 30, upper threaded core sleeve 31, threaded core 32, threaded rotating gear 33, lower threaded sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com