Micro-nano satellite multi-assembly thermal vacuum batched test device and test method

A technology of a micro-nano satellite and a test device, which is applied to the test of the device, the field of the multi-component thermal vacuum batch test device of the micro-nano satellite, can solve the problems of difference, time and economic unbearableness, and achieves reducing the test cost and improving the test. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

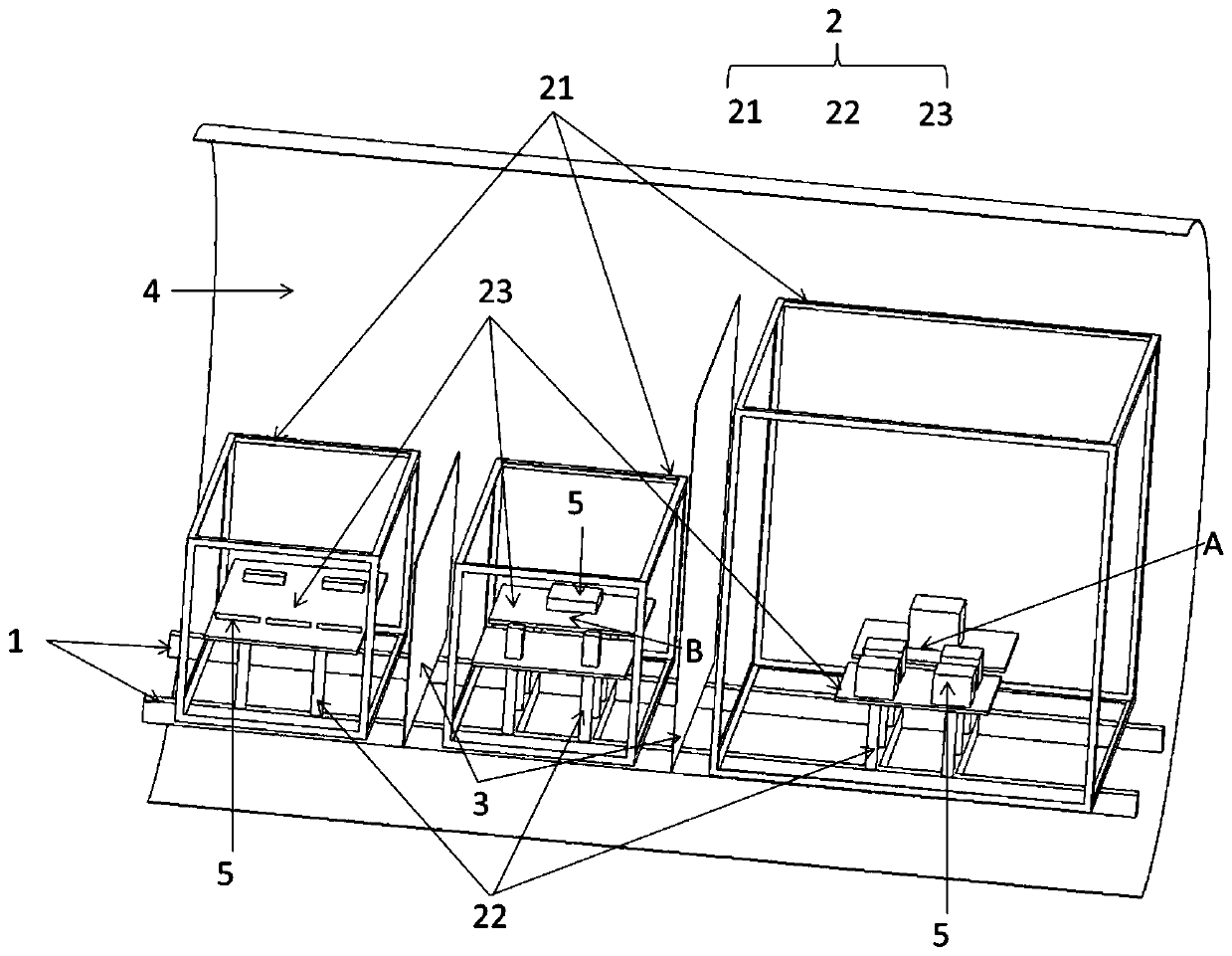

[0028] Reference attached figure 1 , figure 1 It is a schematic diagram of the micro-nano-satellite multi-component thermal vacuum batch test device of the present invention; wherein, the micro-nano-satellite multi-component thermal vacuum batch test device includes a guide rail 1, three heating units 2, and two heat shields 3; the whole device is in Inside the long cylindrical vacuum tank heat sink 4, the guide rail 1 is fixed on the bottom of the vacuum tank heat sink 4, the heating unit 2 and the heat shield 3 are fixed on the guide rail 1, and the three heating units 2 are insulated by two The plates 3 are separated so that direct heat radiation cannot be performed between different heating units 2; the heating unit 2 includes an infrared cage 21, a bracket 22, and a mounting plate 23, wherein the bottoms of the infrared cage 21 and the bracket 22 are respectively fixed on the guide rail 1, The mounting plate 23 is fixed on the top of the bracket 22, and the mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com