Quick-separating roller way conveying line adopted after spraying for direct-buried heat preservation pipe production line

A technology for insulation pipes and production lines, applied in the direction of conveyors, conveyor objects, rollers, etc., can solve the problems of polyurethane damage and easily damaged polyurethane, and achieve the effect of reducing costs and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

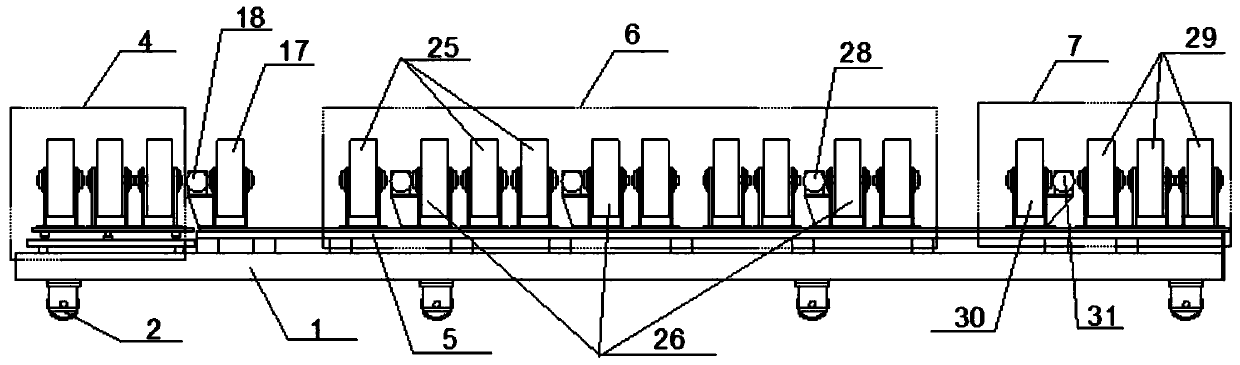

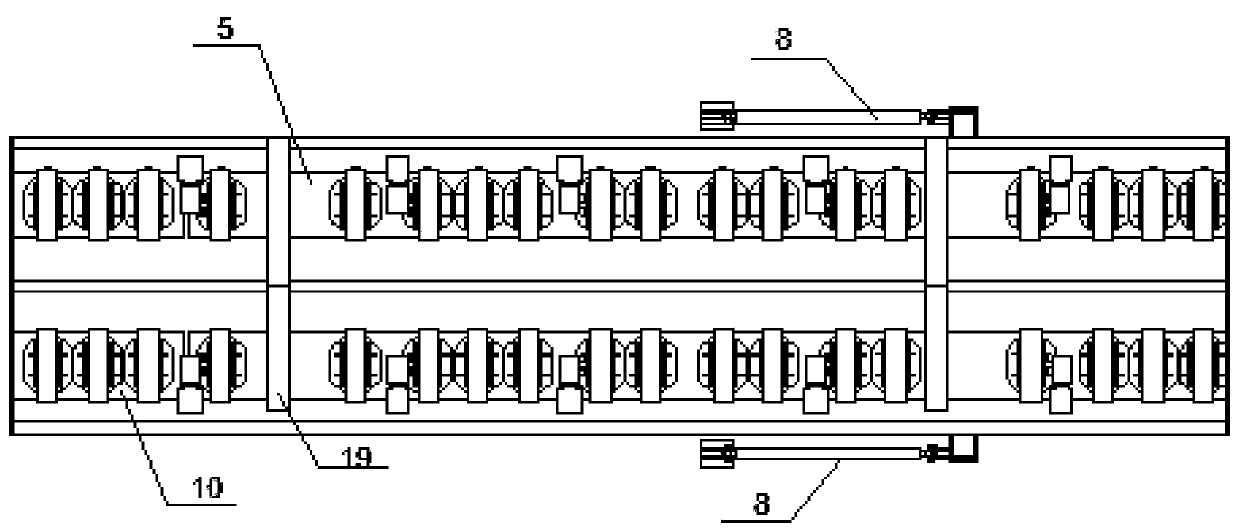

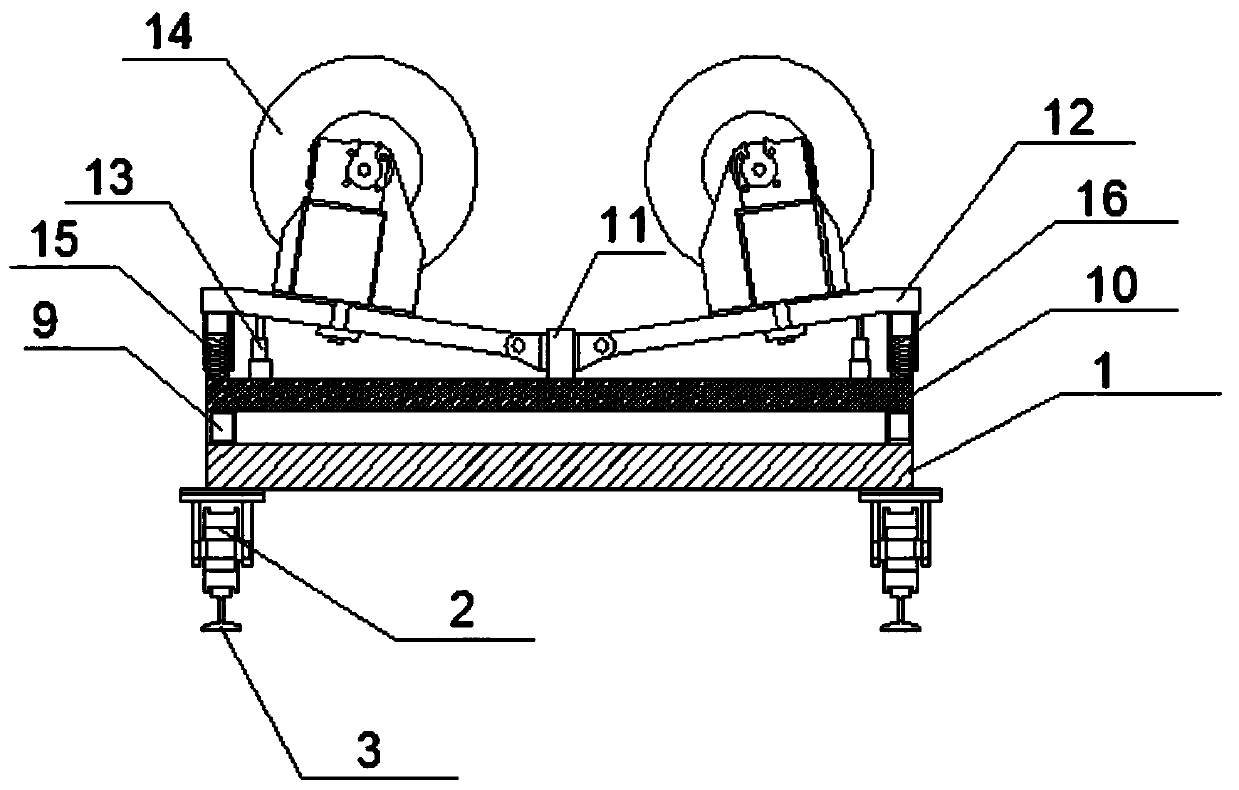

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-Figure 5 As shown in the figure, the sprayed and quickly divided raceway conveyor line used for the direct-buried insulation pipe production line includes a base 1. Several rollers 2 are arranged at the lower end of the base 1. The rollers 2 are slidingly connected with the slide rail 3, and the upper end of the base 1 is provided with There are a lifting runner group 4 and a fixed frame 5. The fixed frame 5 is provided with a first fixed runner group 6 and a second fixed runner group 7. Both sides of the base 1 are provided with a walking cylinder 8 in parallel. The entire conveying line With the overall structure, all the runner groups are arranged on the base 1, and by controlling the walking cylinder 8, the base 1 can be pulled to slide on the slide rail 3 as a whole to realize the separation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com