A high-efficiency palletizer based on a double-gripper truss robot

A technology of truss robots and double grippers, which is applied to the stacking of objects, conveyors, conveyor objects, etc., can solve the problems of strict electrical control requirements, increased structural strength requirements, and high overall cost, and achieve easy maintenance and maintenance. The effect of improving work efficiency and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

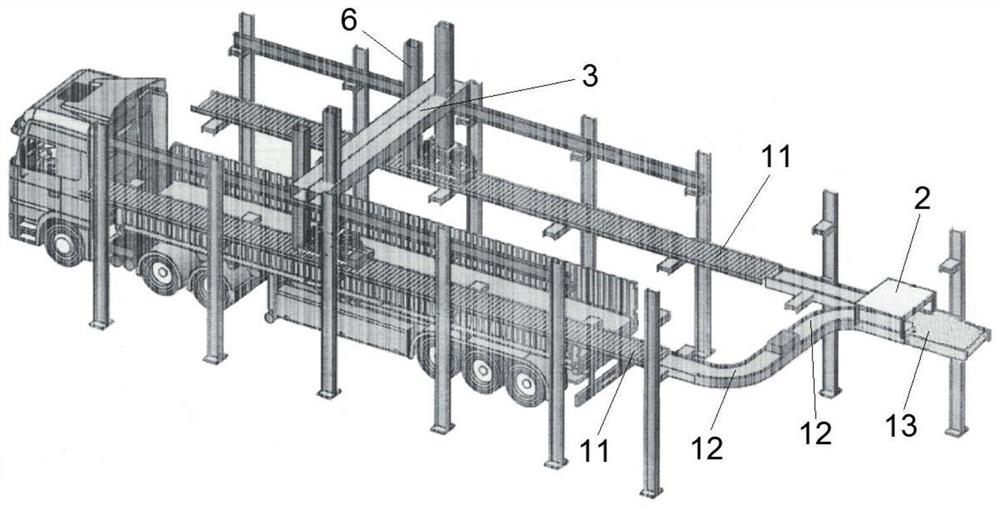

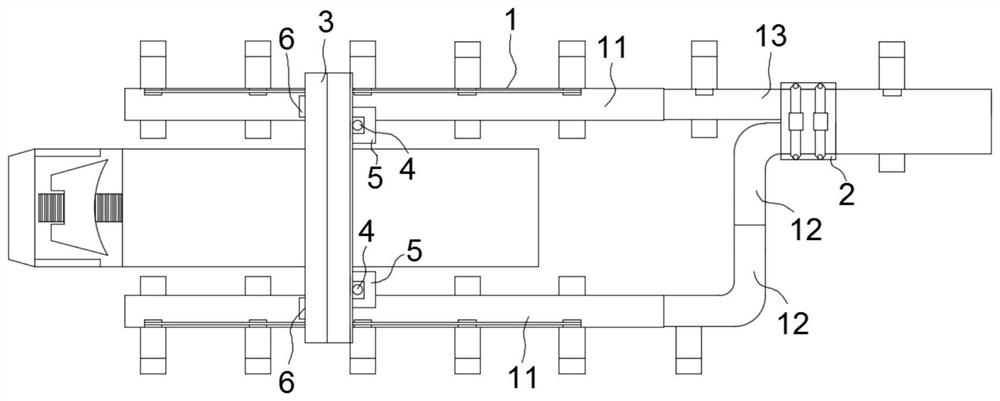

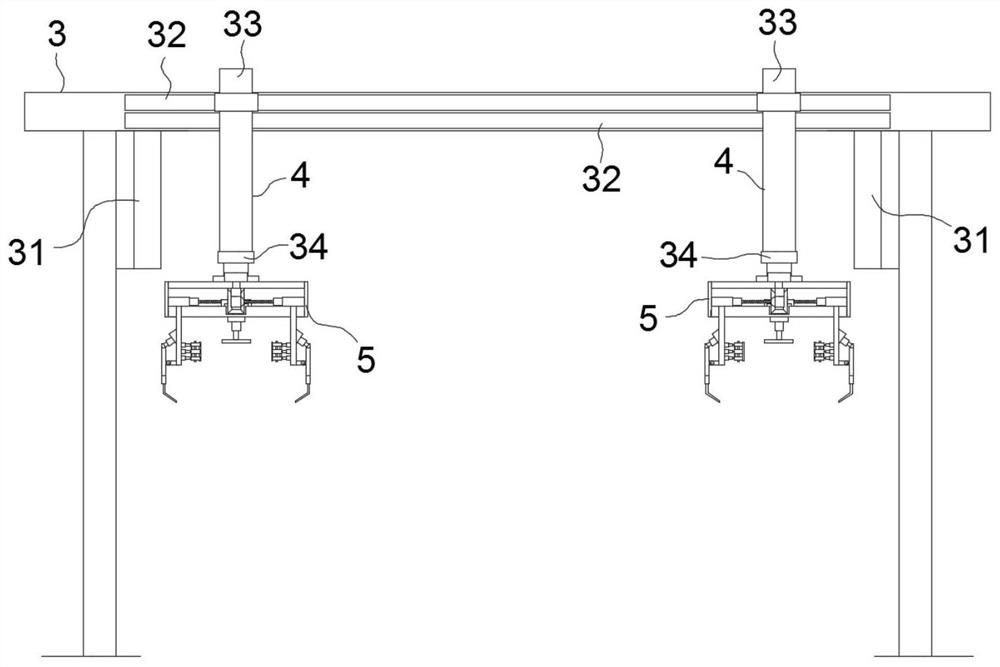

[0056] A high-efficiency palletizer based on a double-handle truss robot, characterized in that it mainly includes a truss handling system, a material delivery system, a control system, and a safety protection system;

[0057] Such as figure 1 and 2 As shown, the material conveying system consists of five conveying lines 1, which are divided into two roller conveying lines 11, two right-angle turning conveying lines 12, and one straight conveying line 13; the two roller conveying lines 11 are arranged in parallel on the left and right sides of the truck On both sides, the rear end of the first roller conveying line 11 is connected with the straight conveying line 13, and the material separation table 2 is arranged on the straight conveying line 13, and the rear end of the second roller conveying line 11 turns at right angles to the first The conveying line 12 is connected, and the second right-angle turn conveying line 12 is spliced with the first right-angle turn conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com