Method and device for treating dirty oil with sulfur-containing sewage

A sewage treatment and sewage oil technology, applied in water/sewage treatment, water/sludge/sewage treatment, hydrocarbon oil treatment, etc., can solve the problems of high treatment cost, difficult effluent treatment, complex process, etc., to achieve The effect of reducing the metal content, reducing the difficulty of post-processing, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

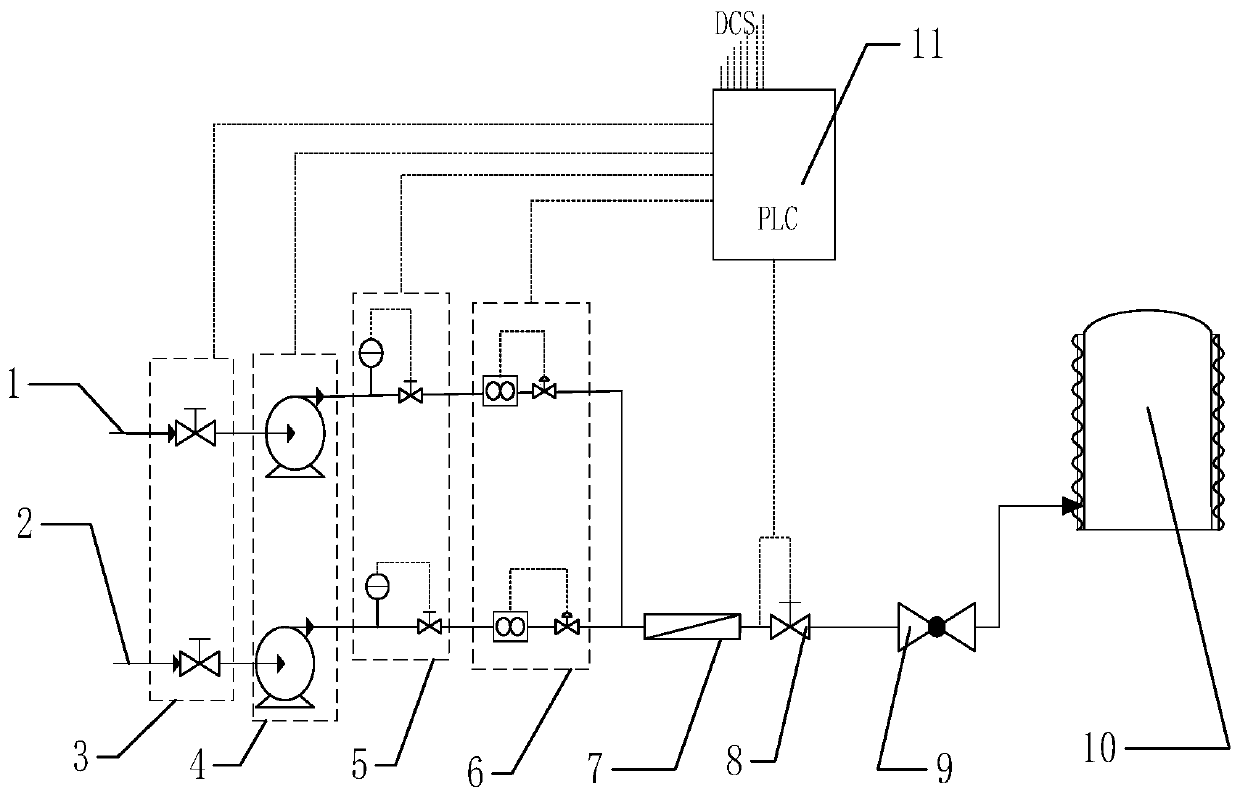

Image

Examples

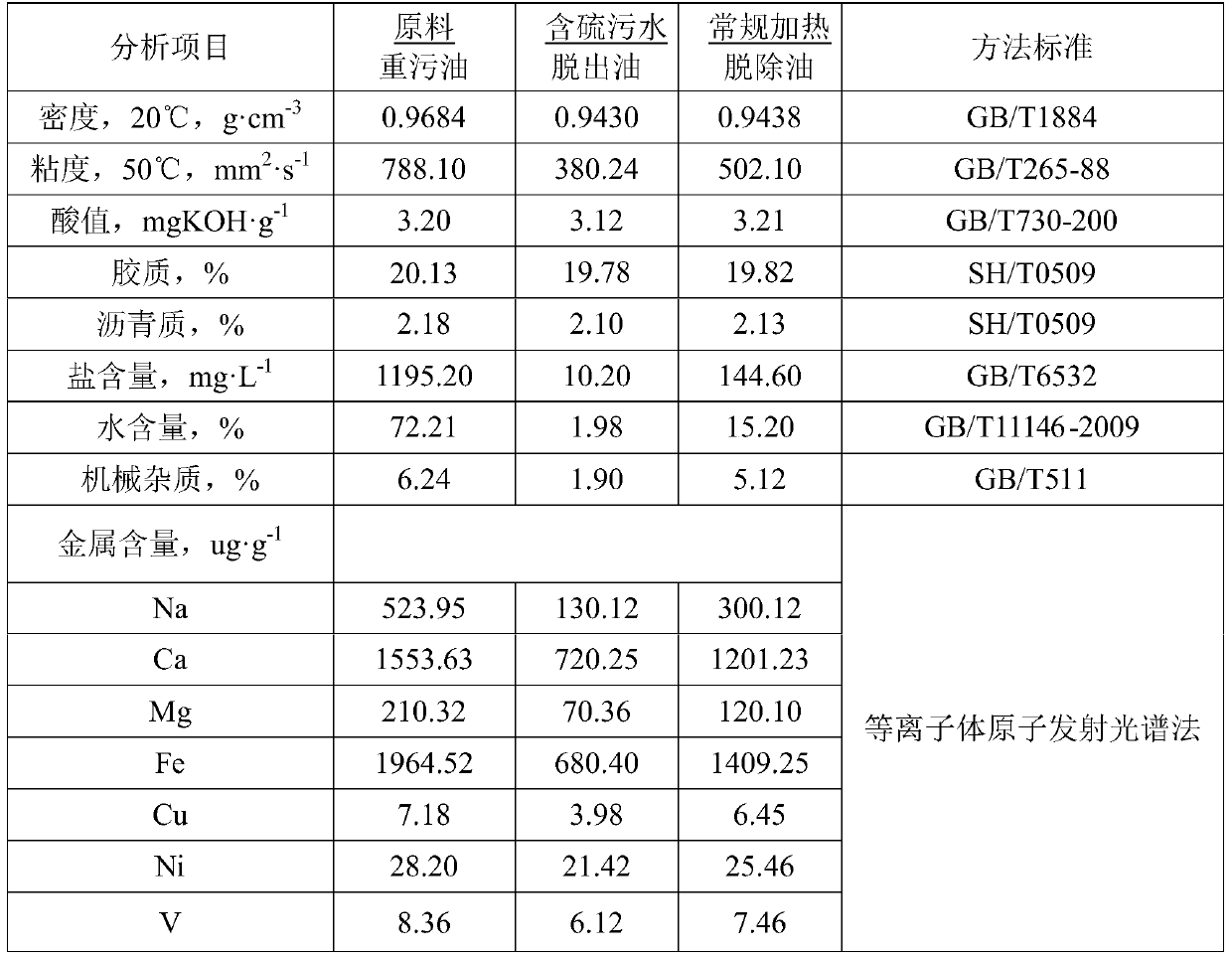

Embodiment 1

[0054] A method for treating sewage oil with sulfur-containing sewage, specifically: injecting a certain proportion of sulfur-containing sewage into the sewage oil, mixing and demulsifying, and then settling in a sedimentation tank to achieve three-phase separation of oil and water residue, and the water content of the treated sewage oil <5%, mechanical impurity content of dirty oil <2%.

[0055] The control conditions of the implementation process of the method for treating slop oil in sulfur-containing sewage according to the present invention are as follows:

[0056] (1) Sulfur-containing wastewater is wastewater containing dissolved hydrogen sulfide and dissolved ammonia nitrogen generated in the petrochemical production process. The sulfur-containing wastewater is controlled to meet sulfide (S 2- ) Content ≥2500mg / L, dissolved ammonia nitrogen (NH 3 -N) Condition of content ≥ 2000mg / L.

[0057] (2) Sulfur-containing sewage is one of acidic, alkaline or neutral. Control the pH val...

Embodiment 2

[0079] A method for treating sewage oil with sulfur-containing sewage, specifically: injecting a certain proportion of sulfur-containing sewage into the sewage oil for mixing and demulsification, and then settling in a sedimentation tank to achieve three-phase separation of oil-water residue, and the water content of the treated sewage oil <5%, mechanical impurity content of dirty oil <2%.

[0080] among them:

[0081] Sulfur-containing wastewater is wastewater containing dissolved hydrogen sulfide and dissolved ammonia nitrogen produced in the petrochemical production process.

[0082] In this Example 2, the sulfide (S 2- ) Content is 2530.3mg / L, ammonia nitrogen (NH 3 -N) The content is 2016.7mg / L.

[0083] The sulfur-containing sewage used in this example 2 is alkaline, with pH=8.

[0084] In Example 2, the mass ratio of sulfur-containing sewage to slop oil was 7 / 10.

[0085] In Example 2, the temperature preheating of the slop oil and sulfur-containing sewage before mixing is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com