Method and device for ultrasonically treating dirty oil through sulfur-containing sewage

A sewage treatment, ultrasonic technology, applied in water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, hydrocarbon oil treatment, etc., can solve the problems of high water content in sewage oil, difficult treatment of extracted water, complicated process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

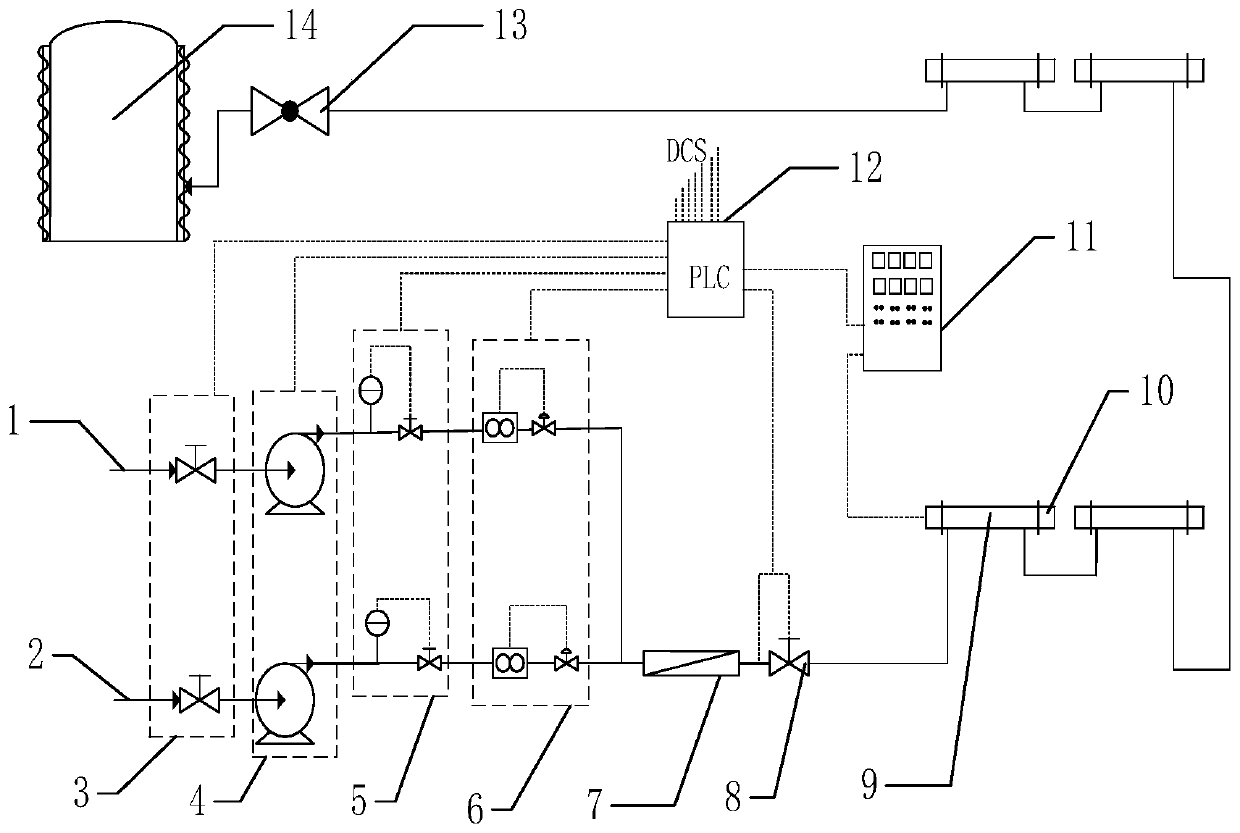

[0074] Ultrasonic sulfur-containing sewage treatment device for dirty oil, including switch valve 3, delivery pump 4, pressure measurement and control 5, flow measurement and control 6, ultrasonic transducer 10, explosion-proof cabinet 11, control unit 12, sewage oil pipeline 1, and sewage oil pipeline 1 After merging with the sulfur-containing sewage pipeline 2, it is connected to the mixer 7, the mixer 7 is connected to the mixing valve 8 through the pipeline, the mixing valve 8 is connected to the ultrasonic action area 9 through the pipeline, and the ultrasonic action area 9 is connected to the mixing switch valve 13 through the pipeline connected, the mixing switch valve 13 is connected with the settling tank 14 through a pipeline.

[0075] On the pipelines connecting the dirty oil pipeline 1, the sulfur-containing sewage pipeline 2 and the mixer 7, an on-off valve 3, a delivery pump 4, a pressure measurement and control 5 and a flow measurement and control 6 are arranged ...

Embodiment 2

[0094] A method for treating dirty oil with ultrasonic sulfur-containing sewage, specifically injecting sulfur-containing sewage into the dirty oil for mixed demulsification, then strengthening the demulsification with ultrasonic waves, and finally settling in a settling tank to realize the three-phase separation of oil, water and slag, and the treated dirty oil The moisture content of the dirty oil is <5%, and the mechanical impurity content of the dirty oil is <1%.

[0095] According to the technical solution of the present invention, the sulfur-containing sewage is wastewater containing dissolved hydrogen sulfide and dissolved ammonia nitrogen produced in the petrochemical production process.

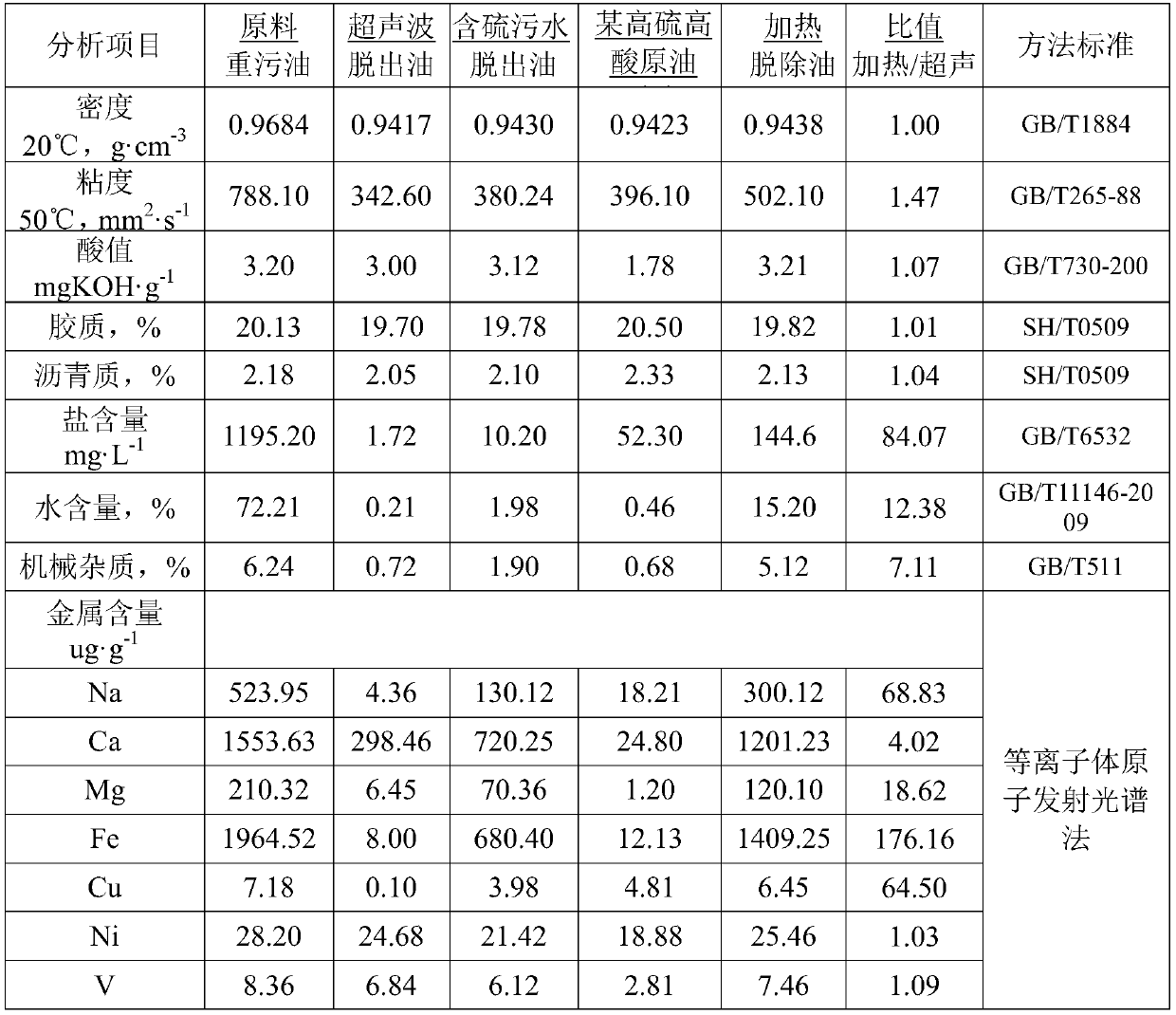

[0096] In this embodiment, material properties and process parameters:

[0097] Sulfur-containing sewage is wastewater containing dissolved hydrogen sulfide and dissolved ammonia nitrogen produced in the petrochemical production process. The sulfide (S 2- ) content 2530.3mg / L, ammon...

Embodiment 3

[0135]A method for treating dirty oil with ultrasonic sulfur-containing sewage, specifically injecting sulfur-containing sewage into the dirty oil for mixed demulsification, then strengthening the demulsification with ultrasonic waves, and finally settling in a settling tank to realize the three-phase separation of oil, water and slag, and the treated dirty oil The moisture content of the dirty oil is <5%, and the mechanical impurity content of the dirty oil is <1%.

[0136] Material properties and process parameters:

[0137] Sulfur-containing sewage is wastewater containing dissolved hydrogen sulfide and dissolved ammonia nitrogen produced in the petrochemical production process. The sulfide (S 2- ) content 12170.8mg / L, ammonia nitrogen (NH 3 -N) content 8341.6mg / L.

[0138] The mass ratio of sulfur-containing sewage to sewage oil is 2 / 10.

[0139] Preheat to 80-95°C before mixing dirty oil with sulfur-containing sewage.

[0140] The mixing strength of the mixing valve f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com