Antibacterial foaming insole and preparing method thereof

A technology of insoles and raw materials, applied in insoles, footwear, applications, etc., can solve problems such as single function and poor antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

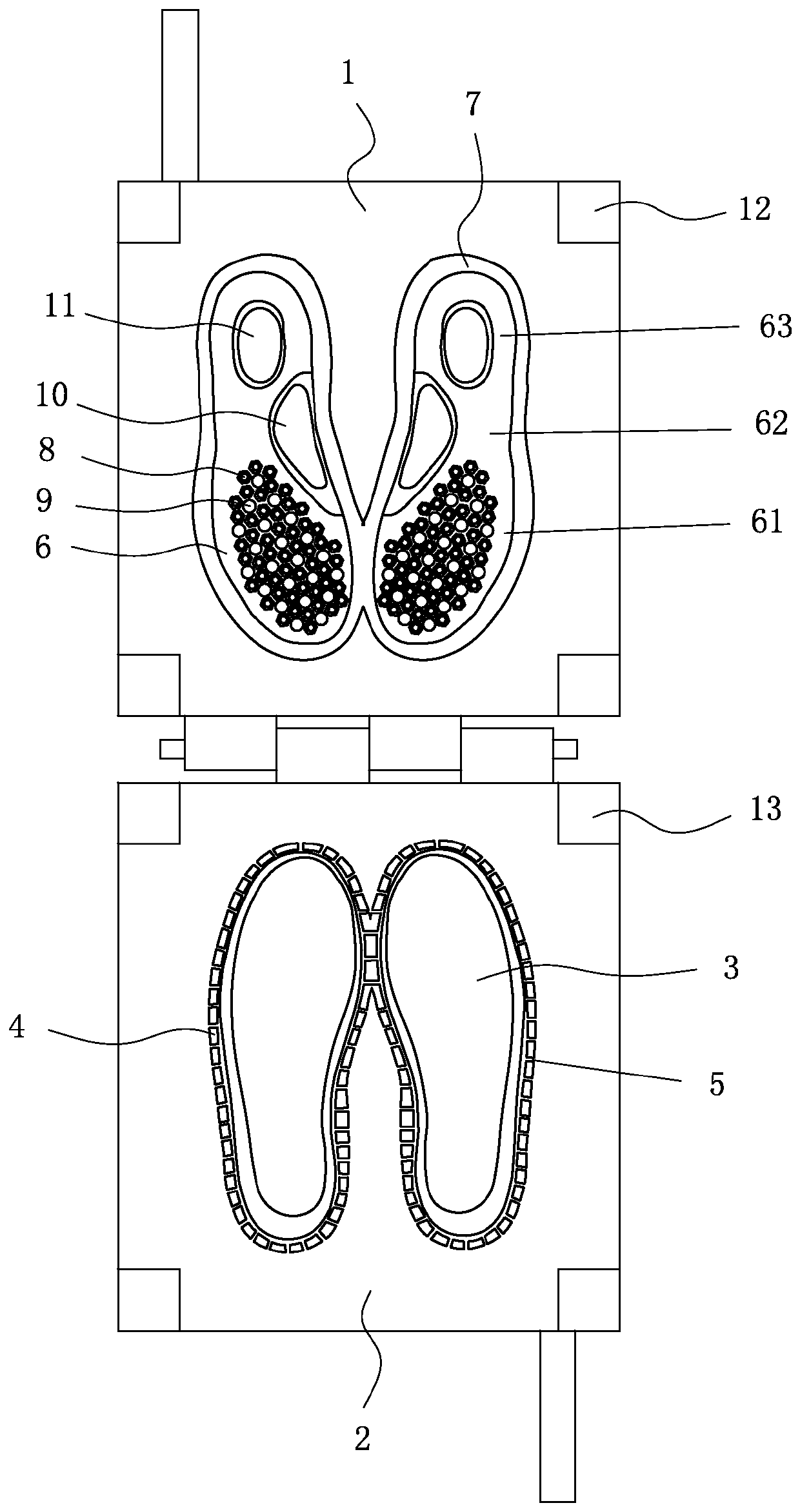

Image

Examples

preparation example Construction

[0029] The preparation method of described antibacterial foaming insole comprises the following processing steps:

[0030] (1) Prepare raw materials: each raw material described in claim 1 is weighed according to proportioning;

[0031] (2) Pretreatment main ingredients: mix natural rubber, butadiene rubber, wear-resistant agent, anti-fungal agent, talcum powder, zinc oxide, accelerator, titanium dioxide, anti-yellowing agent, oxidant, foaming agent, and stir evenly ;

[0032] (3) Banbury mixing: Put the main ingredients mixed evenly in step (2) into the internal mixer preheated to 180°C-185°C, add pure water, Sophora flavescens liquid, Cortex Phellodendri liquid, Scutellaria chinensis liquid, Polygonum cuspidatum liquid , Senecio, Cnidium seed liquid, tea polyphenols and far-infrared powder, the speed of the internal mixer is controlled at 80-100r / min, and the mixer is mixed until it is in a molten state;

[0033] (4) rubber mixing: the article processed in step (3) is refi...

Embodiment 1

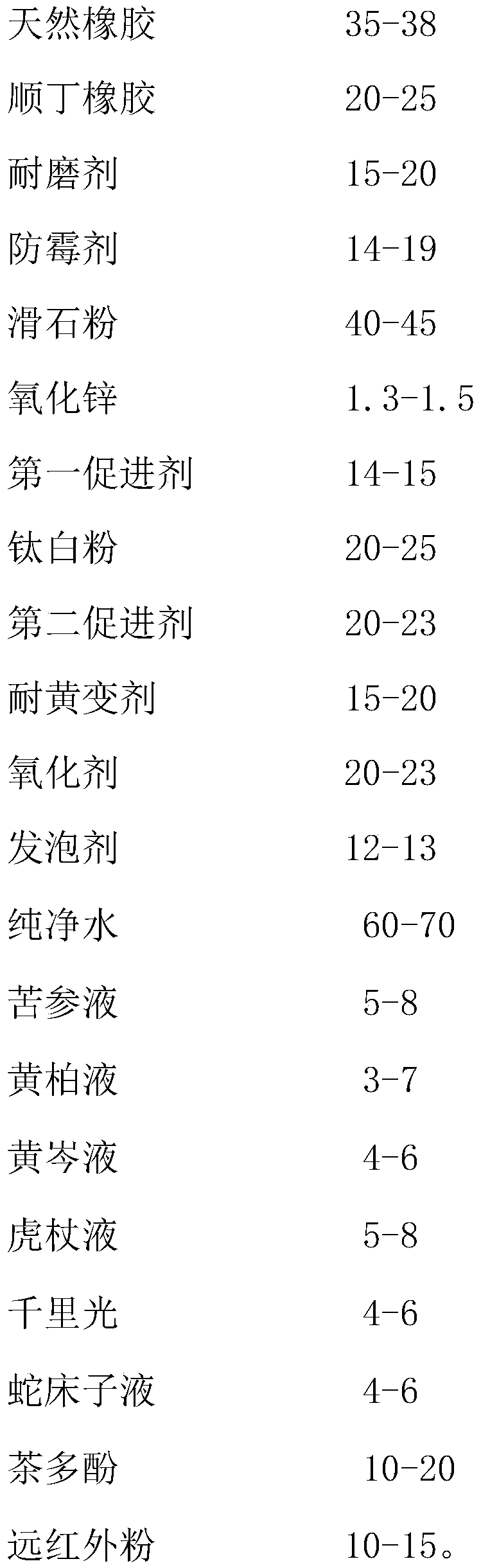

[0038] A kind of antibacterial foaming insole, is made up of each raw material of following parts by weight:

[0039] 36 parts of natural rubber, 24 parts of butadiene rubber, 18 parts of anti-wear agent, 16 parts of antifungal agent, 42 parts of talc powder, 1.4 parts of zinc oxide, 14.5 parts of accelerator DM, 22 parts of titanium dioxide, 20 parts of accelerator M particles 18 parts of anti-yellowing agent, 20 parts of oxidizing agent, 12.5 parts of foaming agent, 70 parts of pure water, 5 parts of Sophora flavescens, 5 parts of Cortex Phellodendron, 5 parts of Scutellaria chinensis, 5 parts of Polygonum cuspidatum, 5 parts of Senecio , 5 parts of cnidium seed liquid, 15 parts of tea polyphenols, and 12 parts of far-infrared powder. Zinc oxide has the effect of improving the fluidity of each component. The foaming agent is used to make the insole bulky. The foaming thickness is controlled at 5-8mm. In this embodiment, the foaming thickness is 6mm. Accelerator DM and accele...

Embodiment 2

[0052] Referring to Example 1, the parts by weight of the raw materials used in this example are different from those in Example 1, and the other parts are the same. An antibacterial foamed insole, which is composed of the following raw materials in parts by weight: 36 parts by weight of natural rubber, 22 parts by butadiene rubber, 17 parts of wear-resistant agent, 18 parts of antifungal agent, 42 parts of talcum powder, 1.3 parts of zinc oxide, 14 parts of accelerator, and 23 parts of titanium dioxide , accelerator M grains 20, anti-yellowing agent 17, oxidizing agent 20, foaming agent 12, purified water 65, flavescens liquid 6, cork cypress liquid 4, scutellaria chinensis liquid 5, knotweed liquid 5, Senecio 5, cnidium seed liquid 5. Tea polyphenols 15, far infrared powder 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com