Production formula of spinning rubber roll for chemical fiber double core-spun yarn

A technology for producing formulas and cots, which is applied in spinning machines, textiles, papermaking, and drafting equipment, etc. It can solve the problems of sticky tapes, unsteady pre-drawing tension, oily wear and grooving, etc., and achieve extended use The effect of lifespan, reduction of maintenance difficulty, and reduction of damage consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

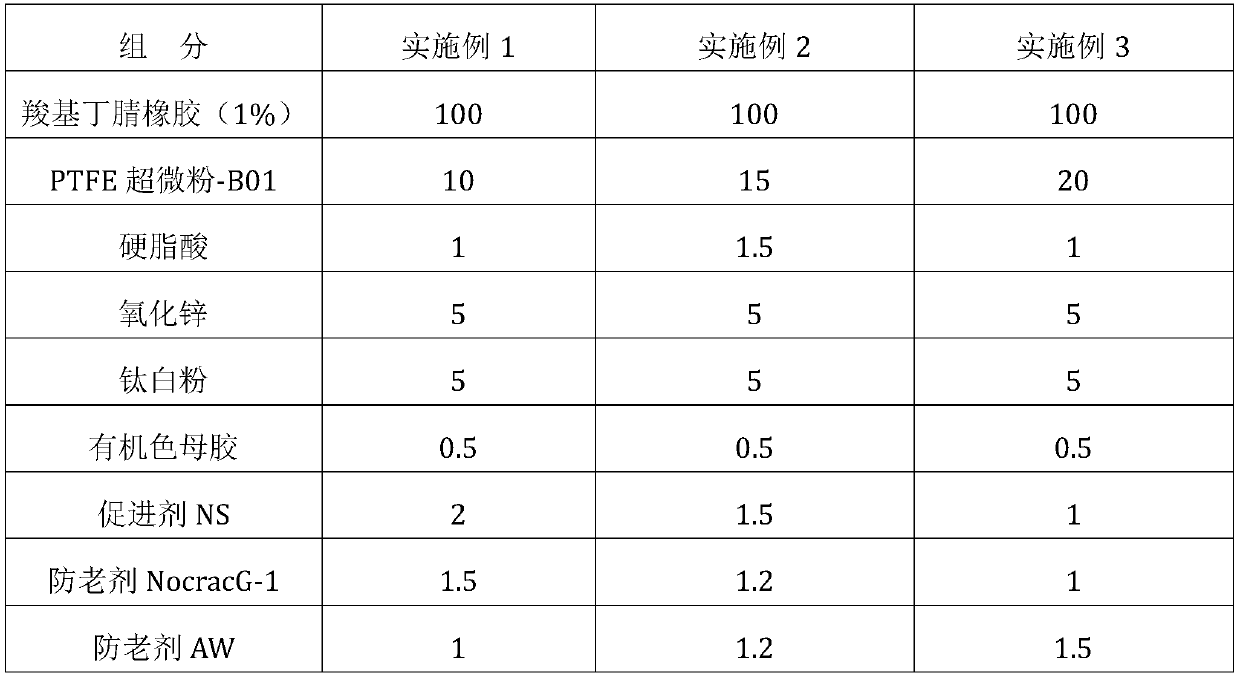

[0018] Embodiment 1~Example 3 Weigh the raw materials according to the parts by weight ratio shown in Table 1, then use a closed rubber mixer to prefabricate nitrile rubber and PTFE ultrafine powder-B01 pre-dispersed mixed rubber, and then pass through a closed type rubber mixer. The rubber mixer is mixed to make rubber products.

[0019] Table 1:

[0020]

[0021]

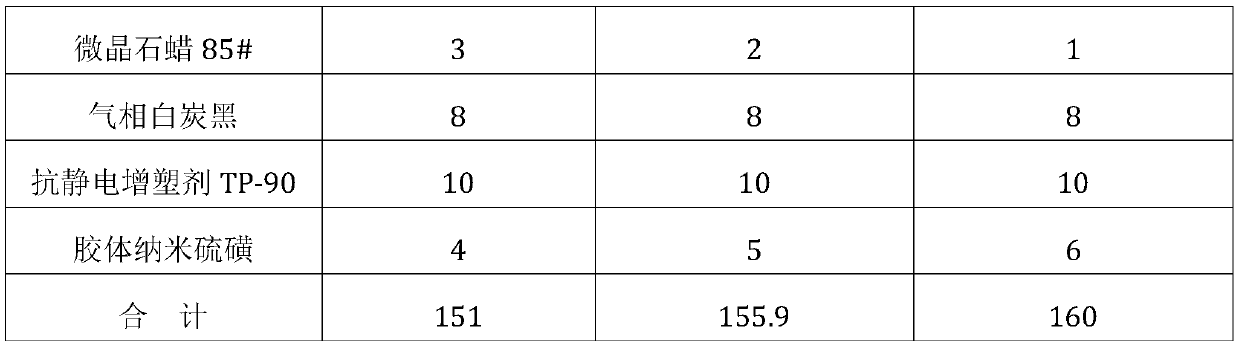

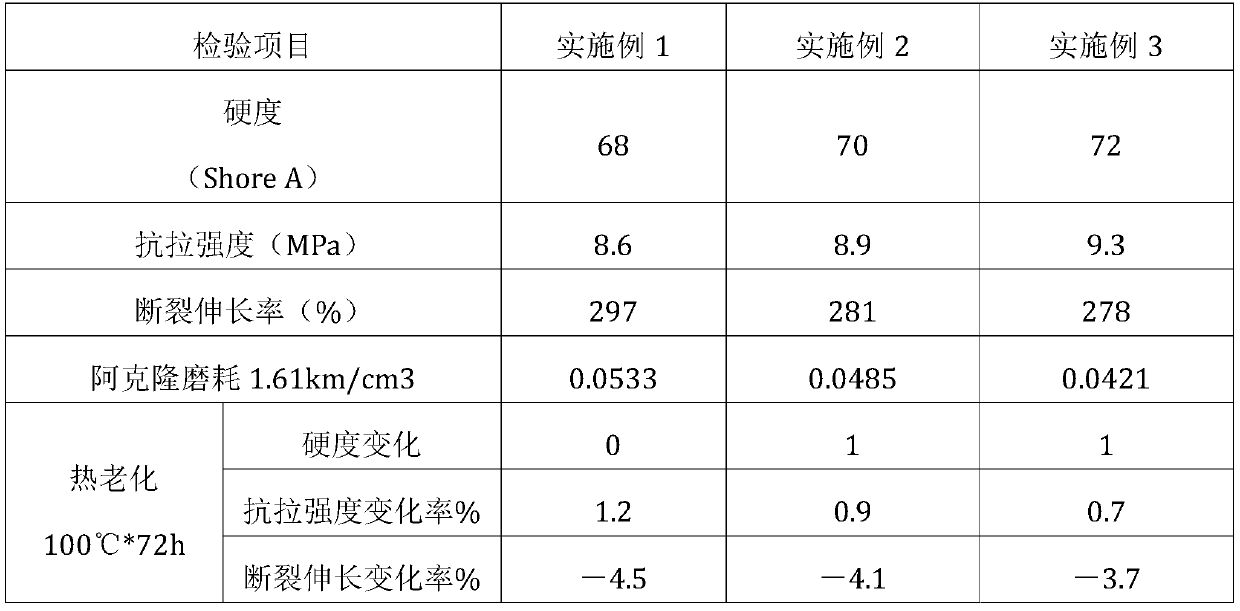

[0022] The rubber products obtained in Examples 1 to 3 are tested according to the testing standards of "GB / T528-2009", "GB / T531.1-2008", "GB / T1689-1998", and "GB / T3512-2001" Test, the results are shown in Table 2:

[0023] Table 2:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com