Preparation method of electrical insulation material for inhibiting reduction of flashover voltage

A technology of electrical insulating materials and flashover voltage, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of high surface resistivity and low surface electric strength, and achieve low surface resistivity and high surface electric strength , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

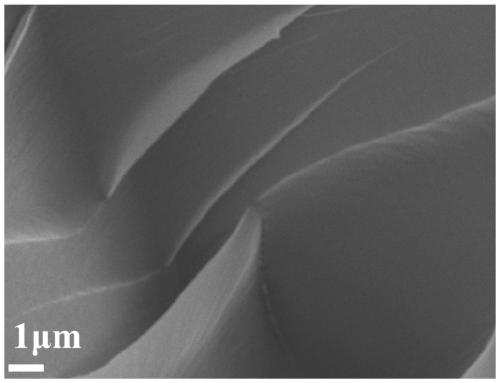

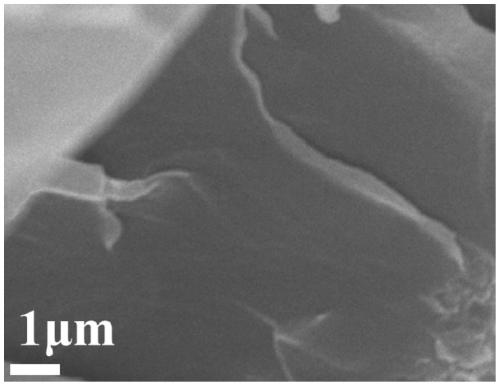

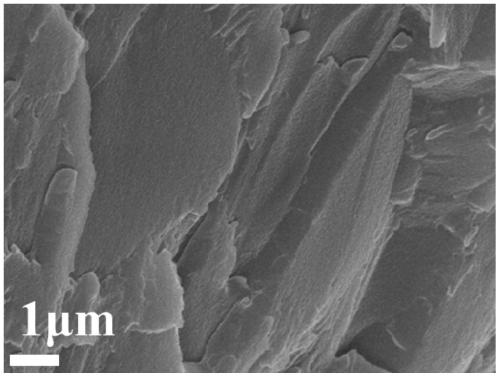

Image

Examples

specific Embodiment approach 1

[0033] Embodiment 1: In this embodiment, a method for preparing an electrical insulating material that suppresses the reduction in flashover voltage is specifically carried out in the following steps:

[0034] 1. TiO 2 Heat the particles to 90-100°C and keep for 30-50min, heat the epoxy resin to 80-90°C and keep for 2-3h, heat the curing agent to 80-90°C and keep for 2-3h;

[0035] 2. Mix the epoxy resin processed in step 1 with the curing agent, add diluent, stir evenly, and then add the TiO treated in step 1 2 Granules, stirred evenly to obtain a mixed solution;

[0036] 3. Coat the surface of the mold with a layer of release agent, put it in an oven, control the temperature at 50-60°C, preheat it for 2-3 hours, then pour the mixed solution obtained in step 2, and then control the temperature at 50-60°C , keep warm for 30-50min, put it into a vacuum drying oven, and evacuate until there are no air bubbles on the surface of the mixed liquid; then raise the temperature to 90...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment is different from Embodiment 1 in that the epoxy resin in step 1 is bisphenol A type epoxy resin. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the curing agent in step 1 is methyltetrahydrophthalic anhydride. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com