Emission-reduction plasma dyeing and finishing process

A plasma and plasma technology, applied in the field of dyeing and finishing technology, can solve the problems of dye dyeing, fading, and large emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

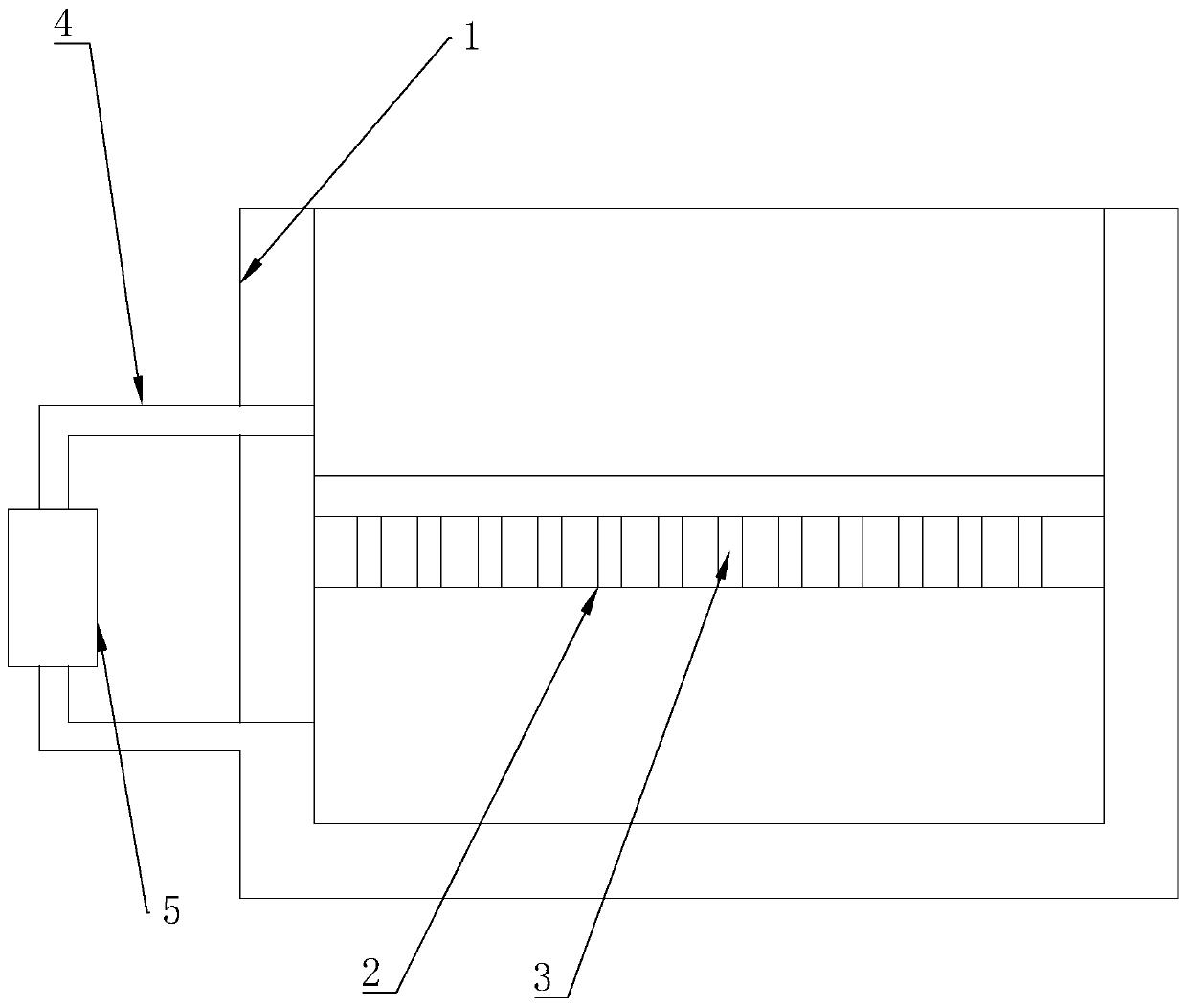

Image

Examples

Embodiment

[0069] An emission-reducing plasma dyeing and finishing process,

[0070] step one:

[0071]Put the polyester cotton cloth in the plasma treatment machine for plasma treatment;

[0072] Step two:

[0073] Dip the polyester-cotton fabric in disperse dyes and dye it under negative pressure cycle conditions;

[0074] Step three:

[0075] washing the fabric to be dyed;

[0076] Step four:

[0077] Dip the completed cleaning cloth into the reduction cleaning solution, and add composite hydrogel to the reduction cleaning solution. The second padding process is still under the condition of negative pressure circulation, and then stand still;

[0078] The composite hydrogel is acrylamide / nano silicon dioxide hydrogel;

[0079] Step five:

[0080] Wrap the cloth after the second dipping with plastic film, and steam it under 100°C steam for 2 minutes;

[0081] Step six:

[0082] Wash and ventilate, then soap and dry.

[0083] In the first step, the plasma treatment parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com