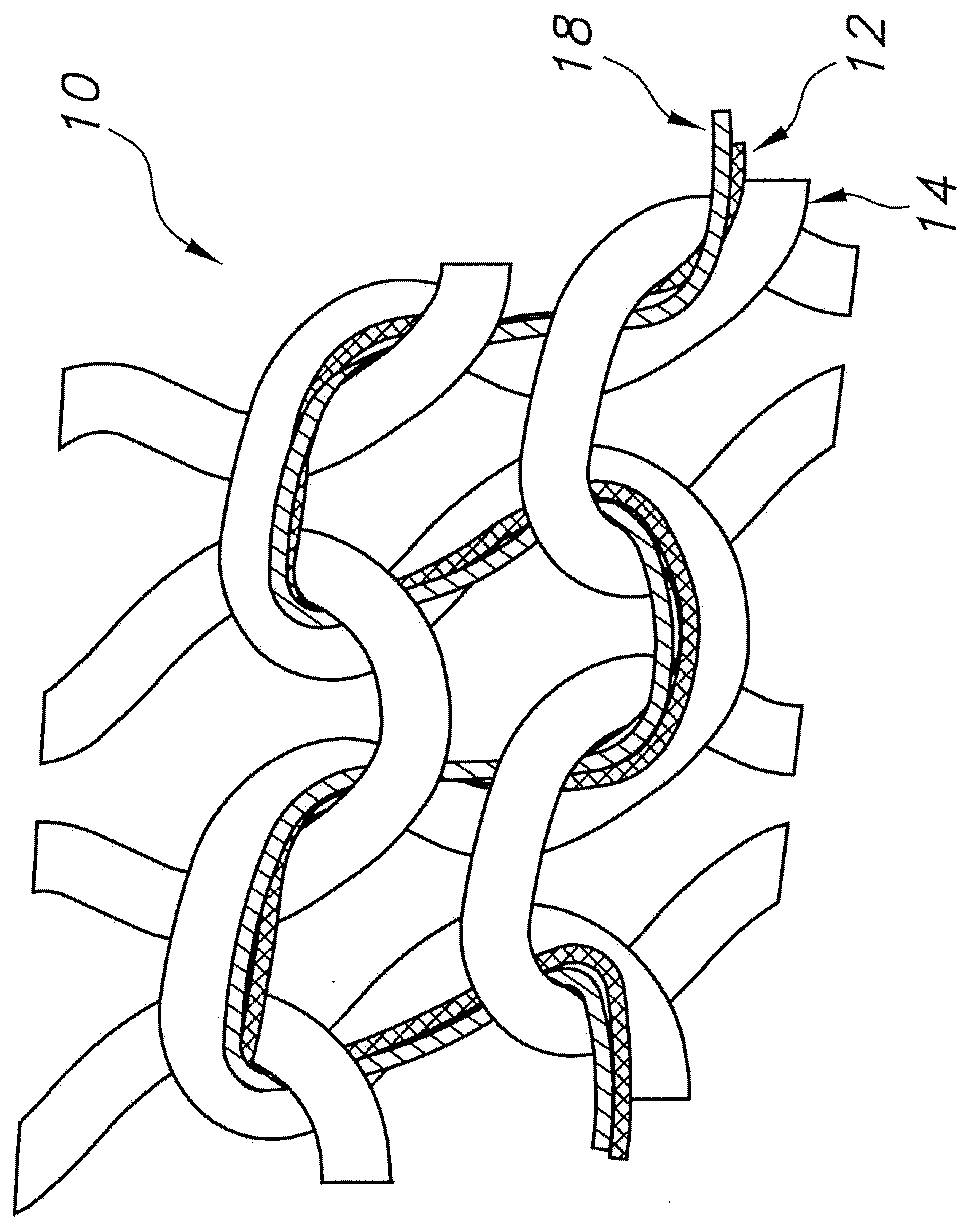

Stretch circular knit fabrics containing elastomeric fiber and polyester bi-component filament, garments made therefrom and a method of making same

An elastomer fiber, circular weaving technology, used in weft knitting, textiles and papermaking, knitting, etc., can solve the problems of severe display, randomness, and undesired appearance and touch of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0127] The following non-limiting examples illustrate the invention and its ability to be used to make a variety of fabrics. The invention is capable of other and different embodiments, and its several details can be modified in various obvious respects, all without departing from the scope and spirit of the invention. Accordingly, these embodiments are to be regarded as illustrative rather than restrictive in nature.

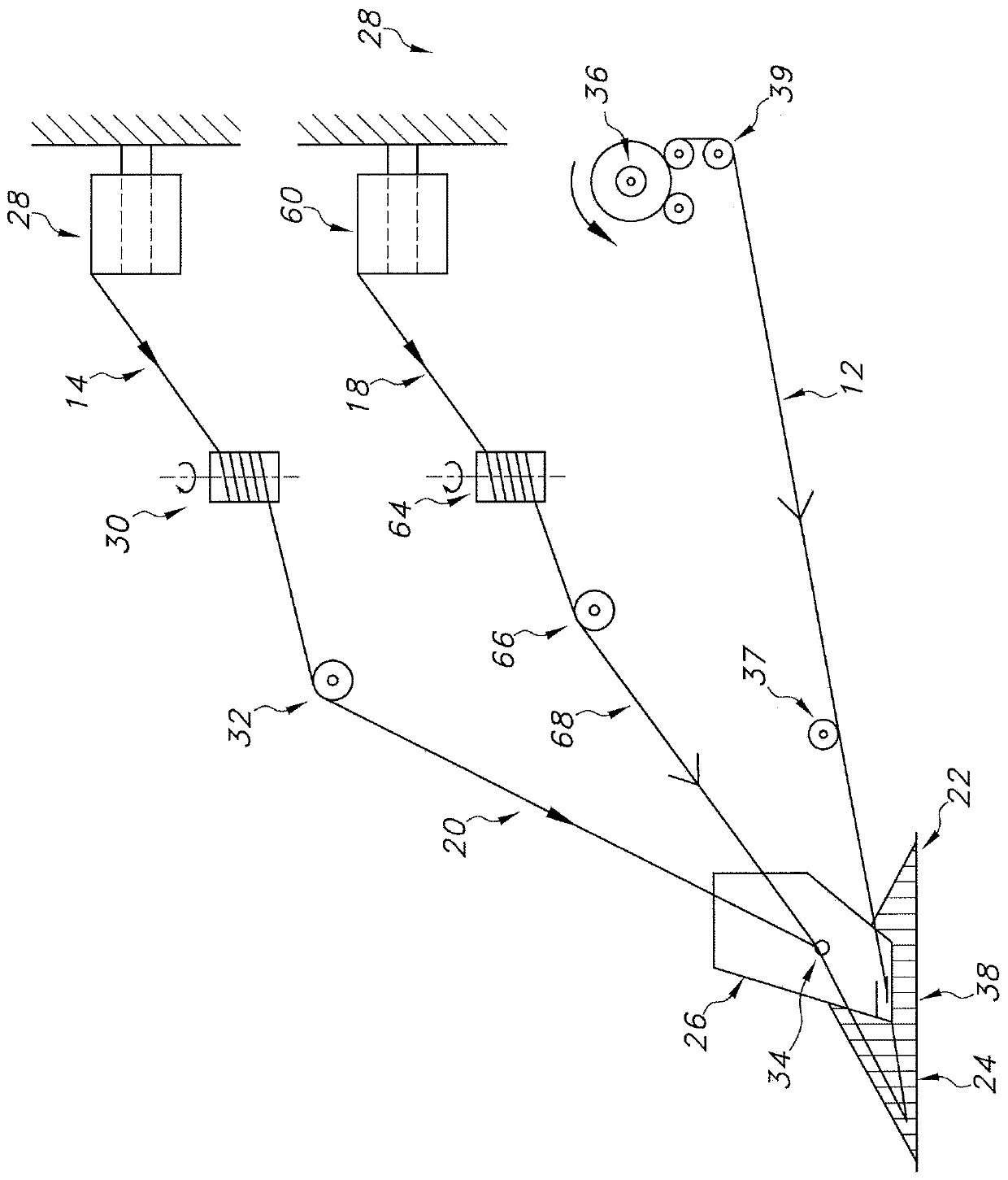

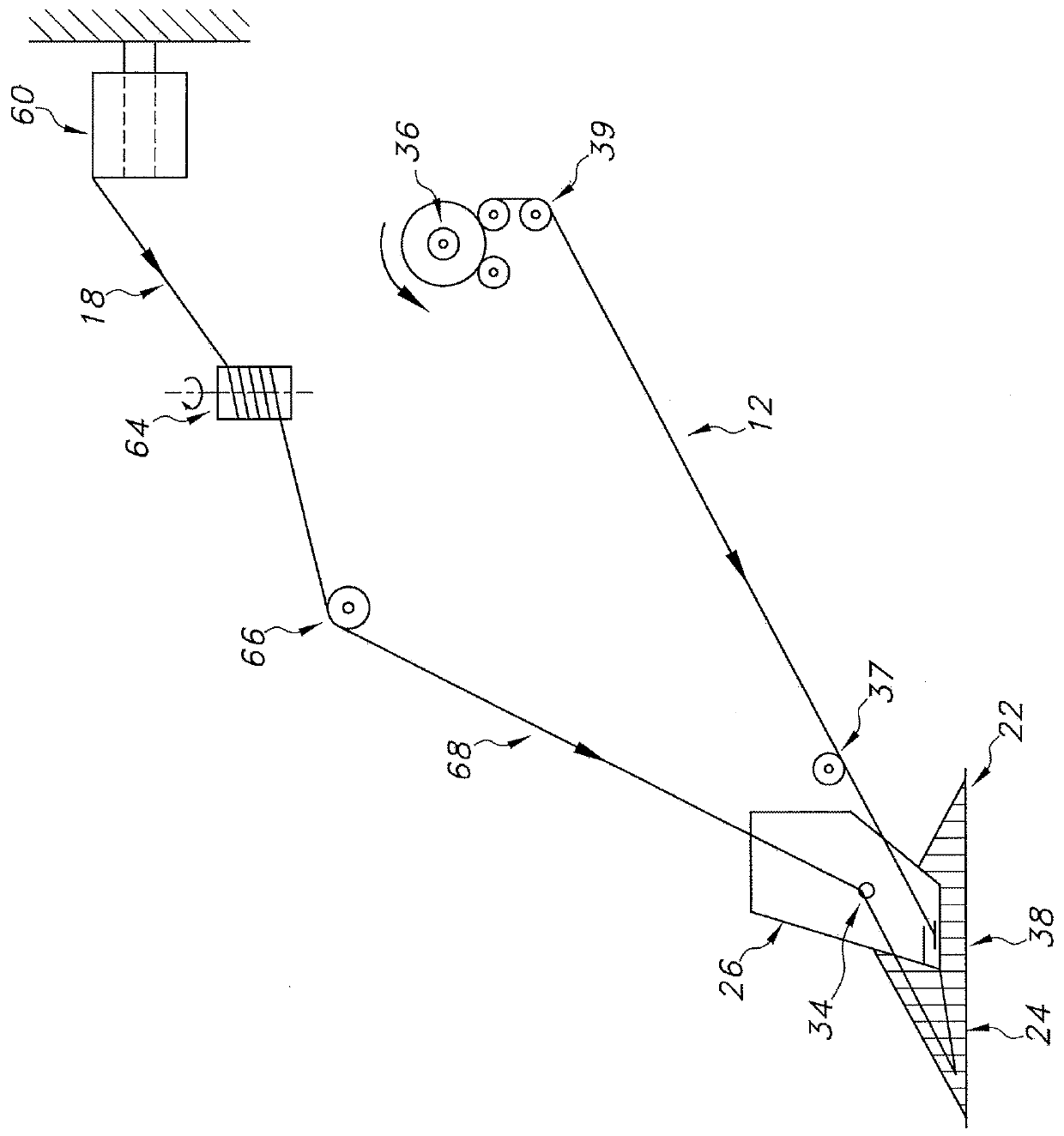

[0128] 28 Gauge Single Ply Circular Knit Fabric with Two Elastane Yarns Plated with Hard Yarns Used in the Examples in Type VX-RDS, 26 Inch Cylindrical Diameter, 28 Gauge (Stitches per Circumference Inches) ), 2232 needles and 42 yarn feeding positions on a Monarch circular knitting machine to be knitted. The circular knitting machine was run at 16 revolutions per minute (rpm). 44 gauge single ply circular knitting fabric was knitted in a Monarch circular knitting machine model VX-3S, 30 inches in diameter, needle 4152, feeder 90, and approximately RPM 20.

...

Embodiment 2

[0139] Example 2: Cotton plain weave fabric with two different elastic fibers

[0140] This sample has the same fabric construction as Example 1C, but incorporates 50D Fibers are excluded. The fabric contains two elastic yarns according to the invention: 40D Spandex and Polyester bicomponent filament. The cotton yarn is a yarn with a count of 50 Ne. Table 1 summarizes the test results. It is evident that the sample has good stretchability (length 85.3% X width 116.4%). The fabric also has low shrinkage. The fabric also had improved recovery (length 205.9% X width 146.2%). The addition of polyester bicomponent filaments significantly increases the retention of the plain weave and limits additional elongation along the width, while increasing recovery along both directions. The fabric exhibits high dimension stability and strong shape retention. The fabric contains fiber, Bicomponent fibers and 67.4% cotton.

Embodiment 3

[0141] Example 3: Single Ply Braid Containing Bielastic Fibers

[0142] This sample has the same fabric construction as in Example 2, except Outer Denier of Fiber: Use 40D T162B with 2.7X draft Fiber and 75d / 34f with 1.10X draft fiber. The hard yarns are 50Ne 100% cotton ring spun yarns with single weave construction. After treatment fabrics have 6.1oz / yard respectively 2 Weight and elongation of 84.5% and 118.3% along the length and width directions. The fabric recovery force was 314.6 grams x 214.6 grams along the length and width directions. As shown, the high denier The fibers help improve fabric recovery in both directions. The fabric contains fiber, Bicomponent fibers and 54.6% cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com