Auto-developing electrostatic spinning stent and preparation method thereof

An electrospinning and auto-imaging technology, applied in the field of medical devices, can solve the problems of non-degradable metal stents, difficulty in follow-up observation, and inability to display the shape of the stent well, and achieve the effect of preventing thrombosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

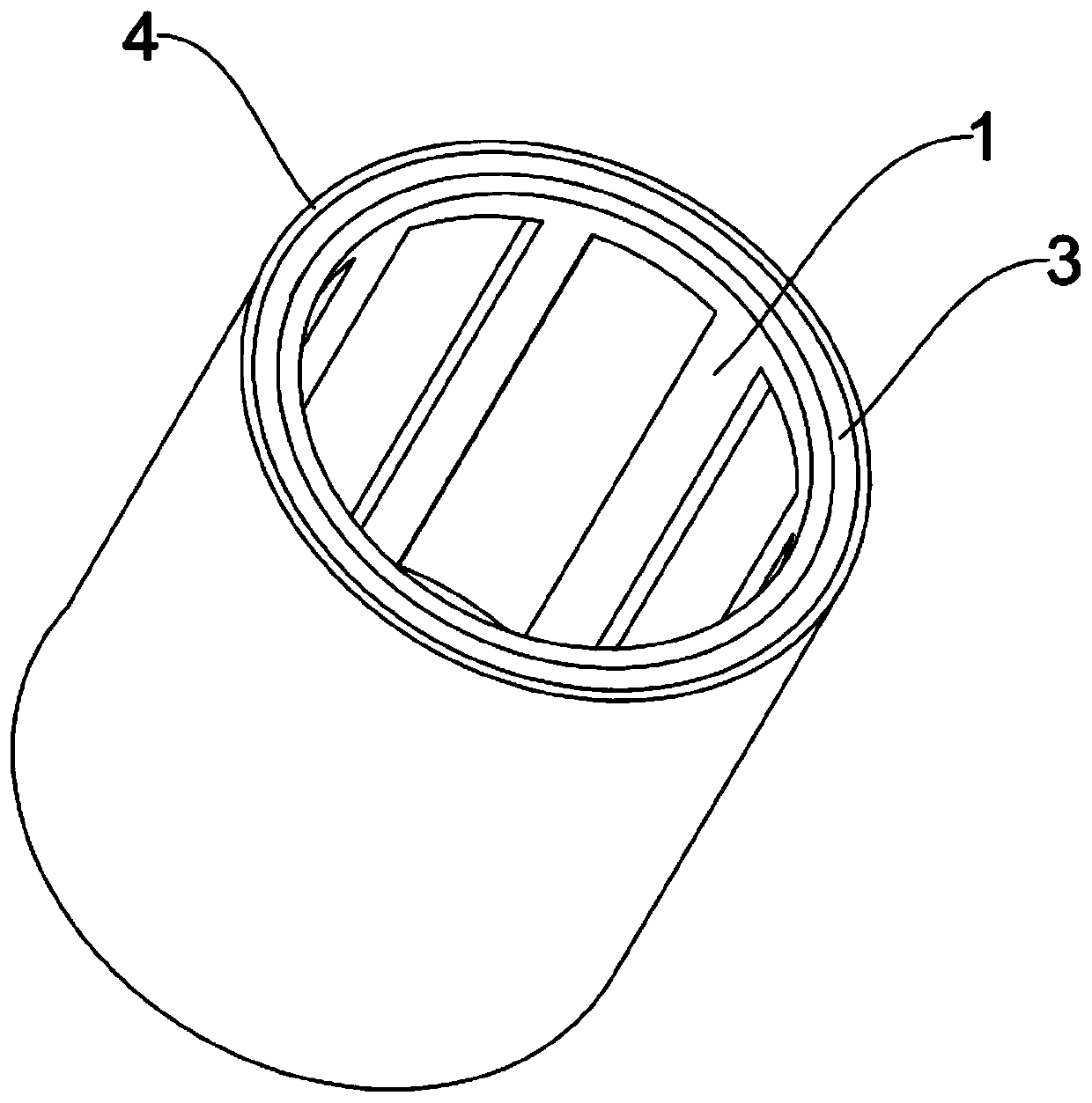

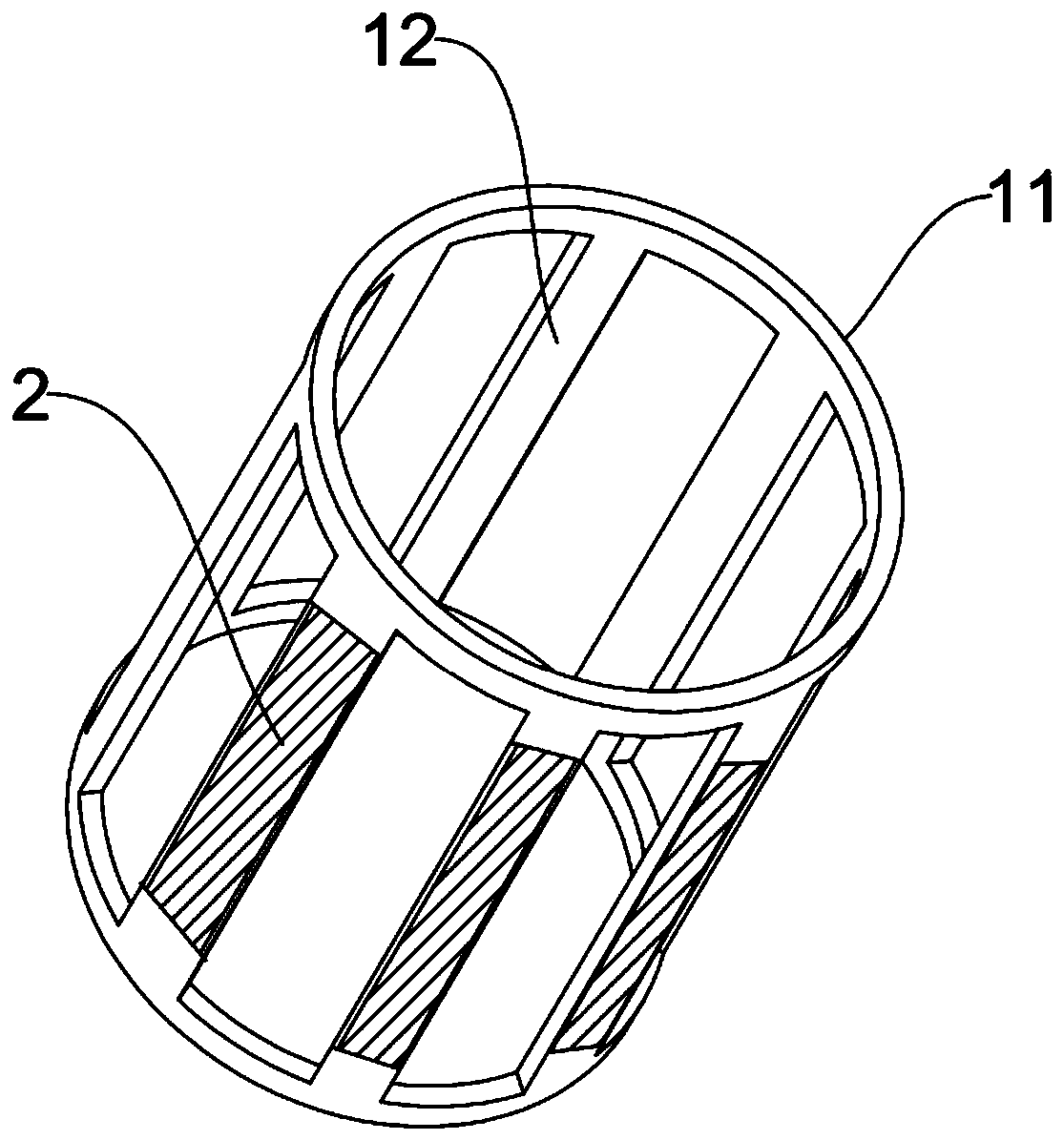

[0026] Embodiment 1: A self-developing electrospinning stent, comprising a stent body 1, a developing layer 2, a spinning layer 3 and a protective layer 4, the stent body 1 includes two symmetrically arranged support rings 11, between the two supports Four support bars 12 are arranged between the rings 11, and the two support rings 11 are coaxially arranged, and the two ends of the support bars 12 are respectively connected with the two support rings 11, as figure 2 As shown, a tubular shape is formed between the support ring 11 and the support bars 12 , and the support bars 12 are evenly distributed on the circumference of the support ring 11 . The developing layer 2 is arranged on the outer surface of the support bar 12, the spinning layer 3 is wrapped around the outer wall of the stent body 1, and the protective layer 4 is coated on the outside of the spinning layer 3 , the thickness of the protection layer 4 is 1um.

[0027] The method for preparing the stent of this emb...

Embodiment 2

[0033] Embodiment 2: A self-developing electrospinning stent, comprising a stent body 1, a developing layer 2, a spinning layer 3 and a protective layer 4, the stent body 1 includes two symmetrically arranged support rings 11, between the two supports Six support bars 12 are arranged between the rings 11, and the two support rings 11 are coaxially arranged, and the two ends of the support bars 12 are respectively connected with the two support rings 11, as figure 2 As shown, a tubular shape is formed between the support ring 11 and the support bars 12 , and the support bars 12 are evenly distributed on the circumference of the support ring 11 . The developing layer 2 is arranged on the outer surface of the support bar 12, the spinning layer 3 is wrapped around the outer wall of the stent body 1, and the protective layer 4 is coated on the outside of the spinning layer 3 , the thickness of the protective layer 4 is 2um.

[0034] The method for preparing the stent of this embo...

Embodiment 3

[0039] Embodiment 3: A self-developing electrospinning stent, including a stent body 1, a developing layer 2, a spinning layer 3 and a protective layer 4, the stent body 1 includes two symmetrically arranged support rings 11, between the two support rings Eight support bars 12 are arranged between the rings 11, and the two support rings 11 are coaxially arranged, and the two ends of the support bars 12 are respectively connected with the two support rings 11, as figure 2 As shown, a tubular shape is formed between the support ring 11 and the support bars 12 , and the support bars 12 are evenly distributed on the circumference of the support ring 11 . The developing layer 2 is arranged on the outer surface of the support bar 12, the spinning layer 3 is wrapped around the outer wall of the stent body 1, and the protective layer 4 is coated on the outside of the spinning layer 3 , the thickness of the protection layer 4 is 3um.

[0040] The method for preparing the stent of thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com