Tellurium Addition Technology of Free Cutting Steel Containing Tellurium

A technology of free-cutting steel and process method, which is applied in the field of iron and steel metallurgy to achieve the effects of reducing production costs, uniform distribution and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

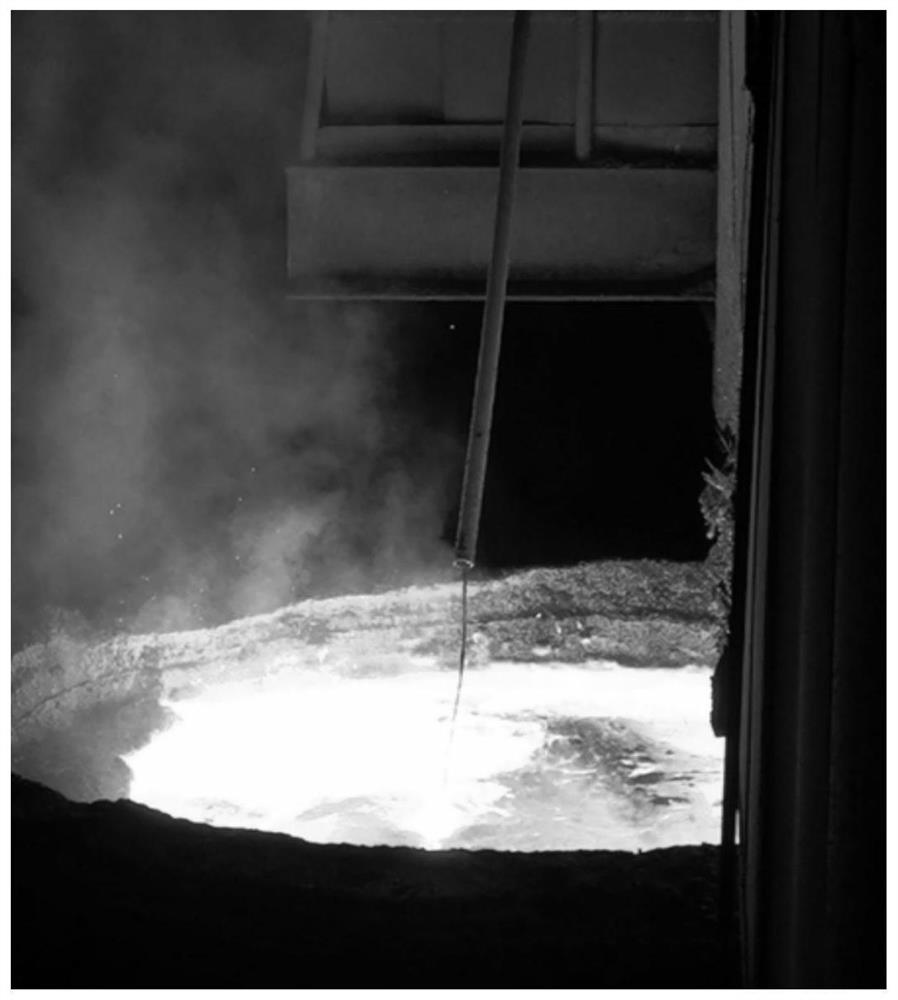

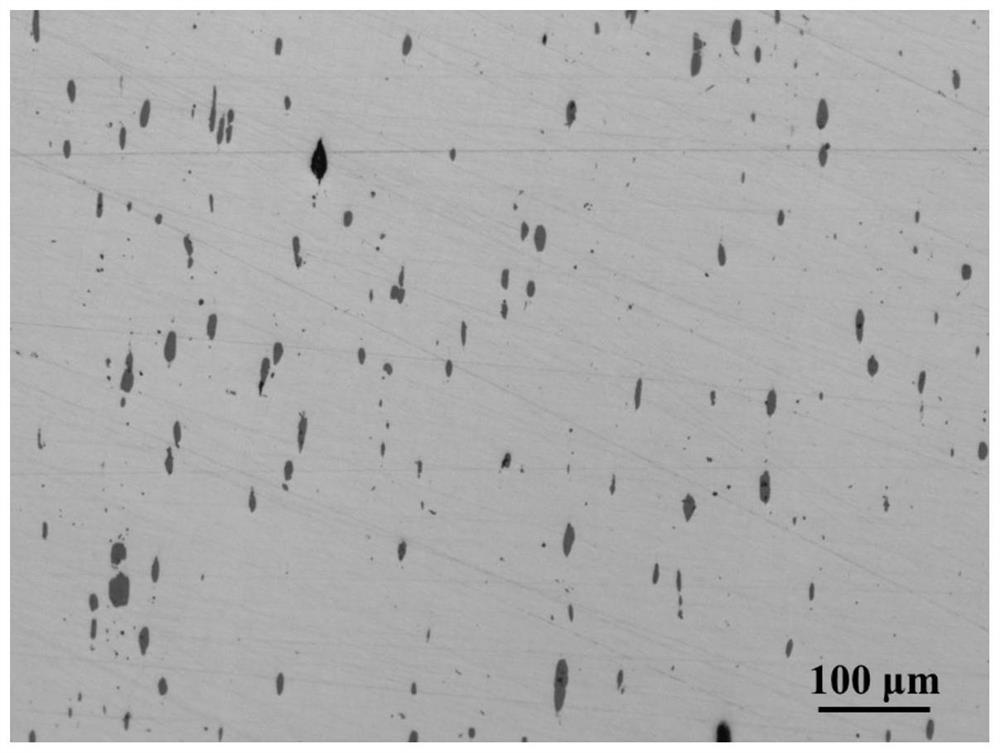

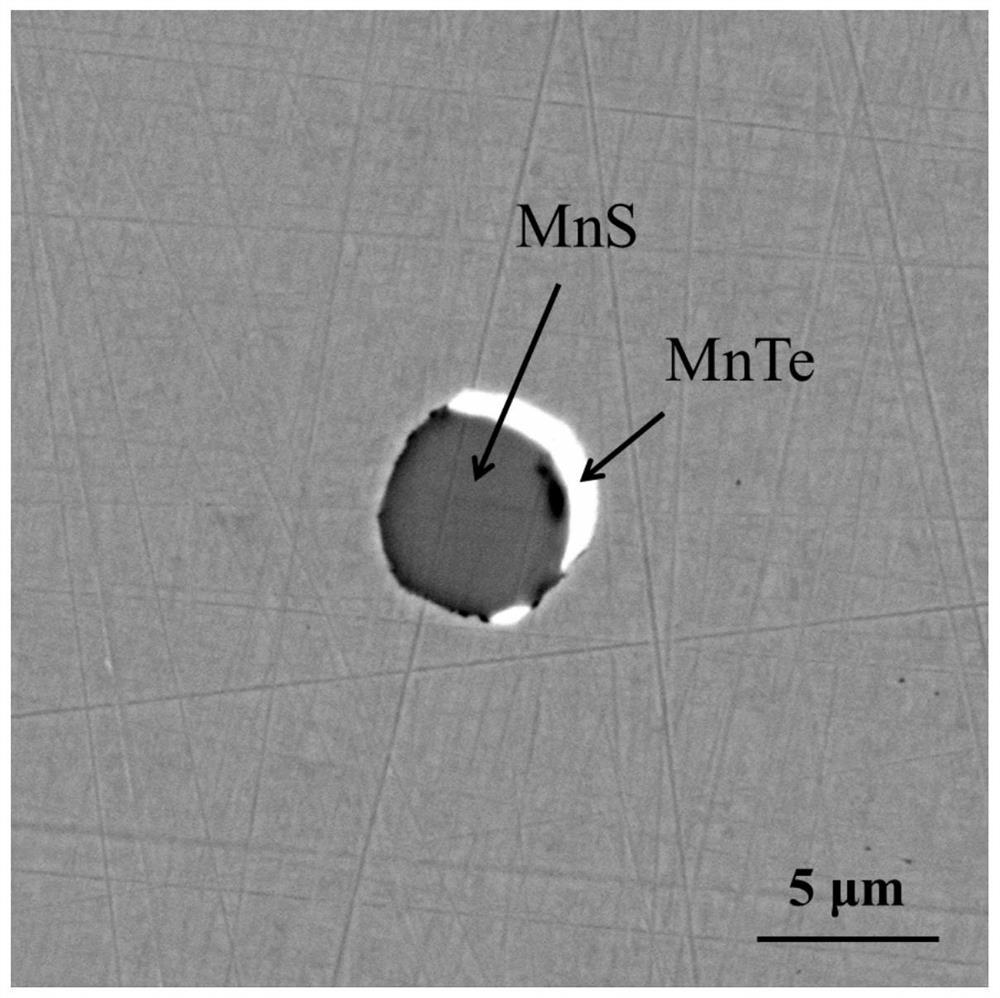

Image

Examples

Embodiment 1

[0062] In this embodiment, a tellurium-containing free-cutting steel process method, the production process of tellurium-containing carbon free-cutting steel is primary smelting→refining→line feeding→continuous casting→rolling. The liquid composition is C: 0.08%, Si: 0.04%, Mn: 1.2%, P: 0.06%, S: 0.32%, and the balance is iron and unavoidable trace elements. The liquid steel composition meets the requirements of this free-cutting steel grade , at the end of molten steel refining, when the other components except tellurium are adjusted, the feeding wire addition process of tellurium-containing cored wire is carried out to prepare the target tellurium-containing free-cutting molten steel. The feeding wire addition process includes the following steps :

[0063] a. Control the production conditions before feeding the line, mainly to control the molten steel slag layer, temperature and oxygen activity to meet certain conditions:

[0064] The thickness of the molten steel slag lay...

Embodiment 2

[0081] This embodiment is basically the same as Embodiment 1, especially in that:

[0082] In this embodiment, a tellurium-containing free-cutting steel process method, the production process of tellurium-containing carbon free-cutting steel is primary smelting→refining→line feeding→continuous casting→rolling. The liquid composition is C: 0.14%, Si: 0.05%, Mn: 1.3%, P: 0.10%, S: 0.33%, and the balance is iron and unavoidable trace elements. The liquid steel composition meets the requirements of this free-cutting steel type , at the end of molten steel refining, when the other components except tellurium are adjusted, the feeding wire addition process of tellurium-containing cored wire is carried out to prepare the target tellurium-containing free-cutting molten steel. The feeding wire addition process includes the following steps :

[0083] a. Control the production conditions before feeding the line, mainly to control the molten steel slag layer, temperature and oxygen activ...

Embodiment 3

[0101] This embodiment is basically the same as the previous embodiment, and the special features are:

[0102] In this embodiment, a tellurium-containing free-cutting steel process method, the production process of tellurium-containing carbon free-cutting steel is primary smelting→refining→line feeding→continuous casting→rolling. The liquid composition is C: 0.14%, Si: 0.05%, Mn: 0.8%, P: 0.10%, S: 0.25%, and the balance is iron and unavoidable trace elements. The liquid steel composition meets the requirements of this free-cutting steel type , at the end of molten steel refining, when the other components except tellurium are adjusted, the feeding wire addition process of tellurium-containing cored wire is carried out to prepare the target tellurium-containing free-cutting molten steel. The feeding wire addition process includes the following steps :

[0103] a. Control the production conditions before feeding the line, mainly to control the molten steel slag layer, tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com