Tunnel supporting lining with buffer performance and construction method of tunnel supporting lining

A tunnel and lining technology, which is applied in the field of tunnel support lining and construction with cushioning performance, can solve problems such as easy deformation or fracture, easy softening, and large deformation of soft rock, so as to improve connection strength and stability, and improve support Strength and the effect of improving support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

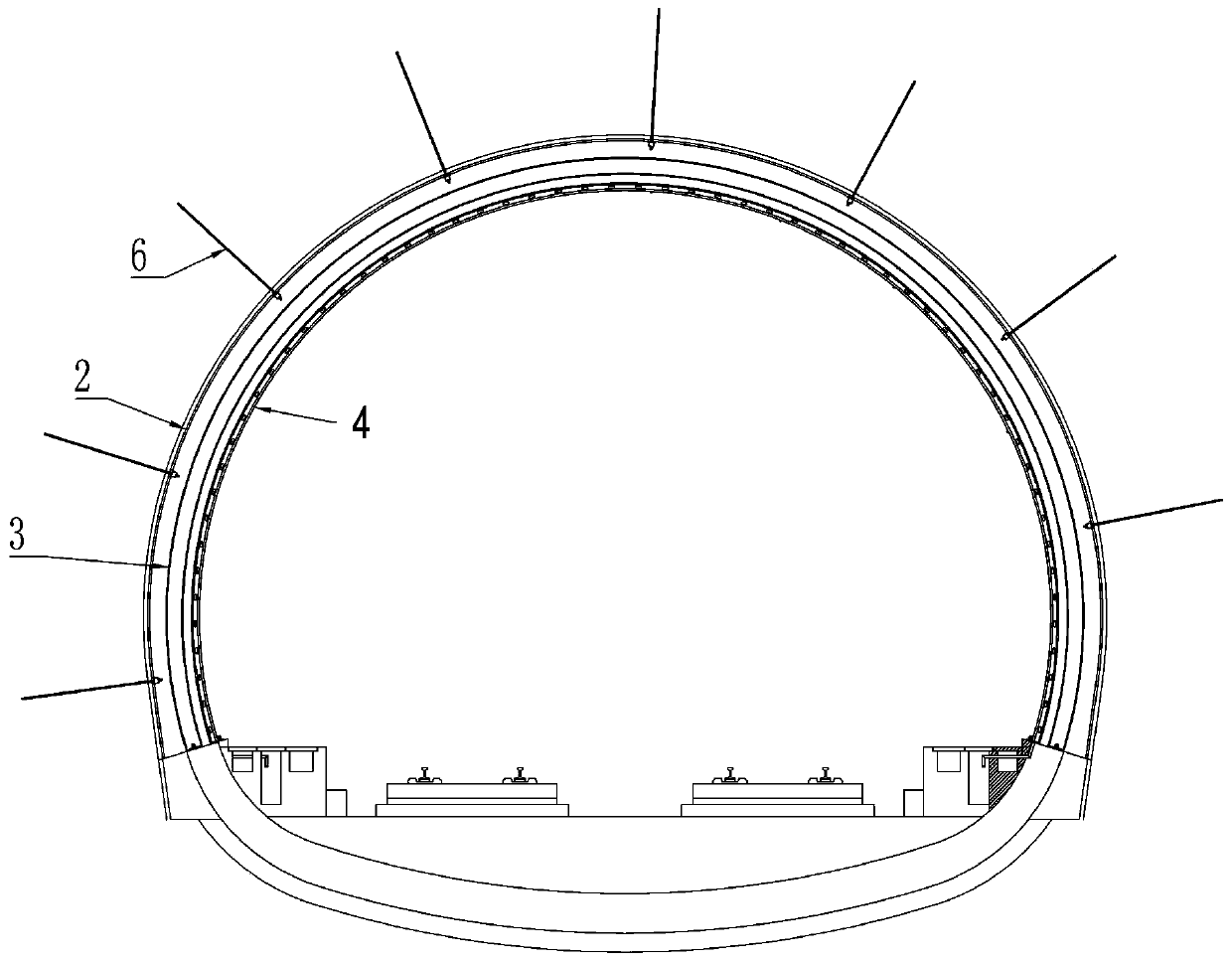

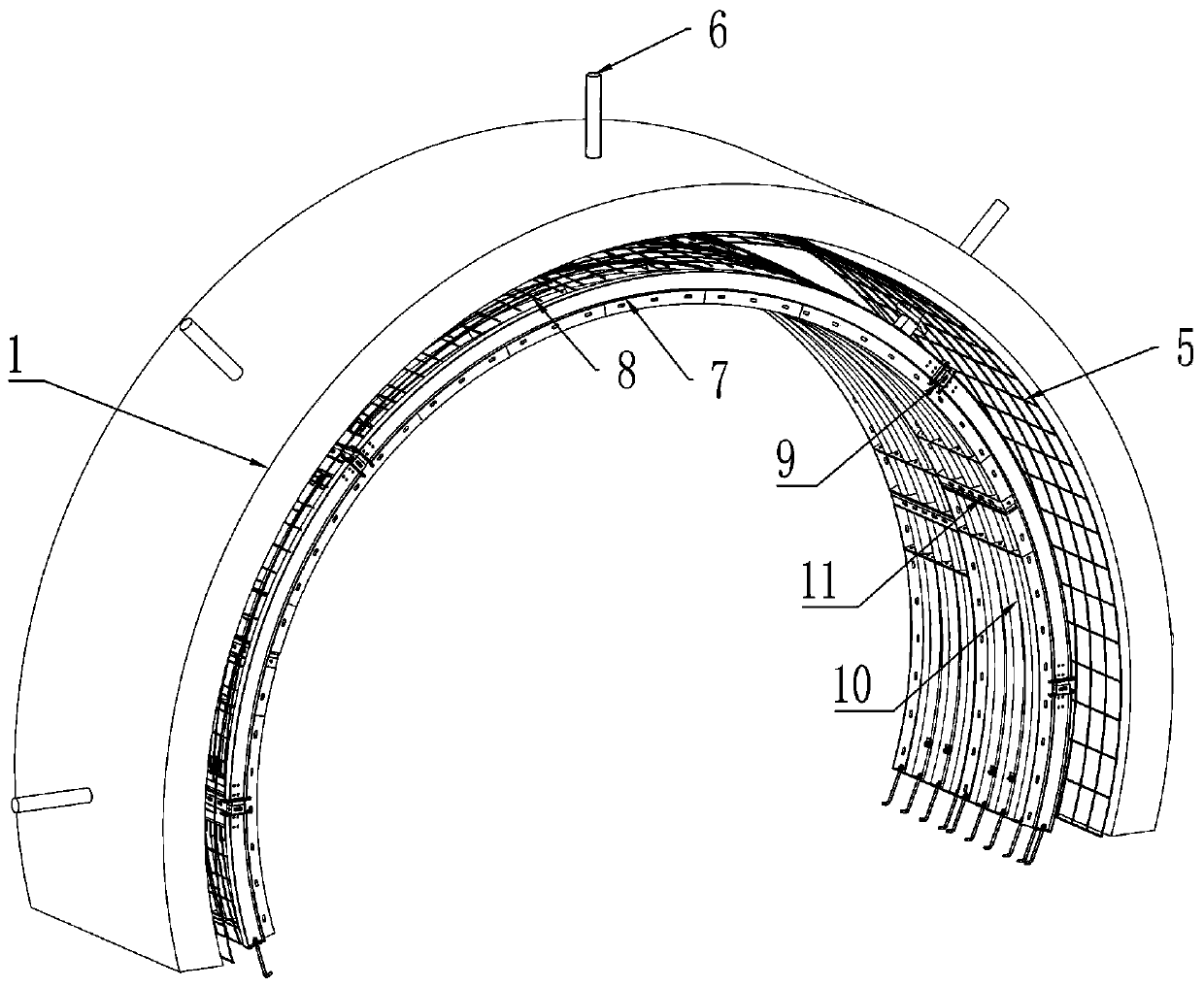

[0043] Such as Figure 1 to Figure 8 As shown, a tunnel support lining with cushioning performance includes a support body located in the tunnel rock wall 1 and matching its arch shape. The support body includes an outer layer support body 2 arranged from outside to inside, a middle layer The supporting body 3 and the inner layer supporting body 4, the two ends of the middle layer supporting body 3 and the inner layer supporting body 4 are fixed with the tunnel invert; the outer layer supporting body 2 includes a flexible net 5 , the flexible net 5 is in contact with the tunnel rock wall 1, and fixed with the tunnel rock wall 1 by means of a plurality of decompression bolts 6 arranged at intervals; one end of the decompression bolt 6 is embedded in the tunnel rock wall 1, and the other end is connected to the tunnel rock wall 1 The flexible net 5 is fixed.

[0044] Such as figure 2 As shown, the flexible net 5 of the outer support body 2 is a steel wire net, and the decompr...

Embodiment 2

[0067] On the basis of Example 1, such as Figure 9As shown, the decompression anchor rod 6 is provided with a top plate 601, a decompression member 602 and a nut 603; the top plate 601 is inside the flexible net 5 and is in contact with it; the nut 603 is threadedly connected with the decompression anchor rod 6; The decompression piece 602 is located between the top plate 601 and the nut 603; the top plate 601 is used to make the flexible net 5 fit the tunnel rock wall 1, the decompression piece 602 can play a buffering role when the tunnel deforms, and the decompression piece 602 can be It can be a spring, rubber or a composite of spring and rubber.

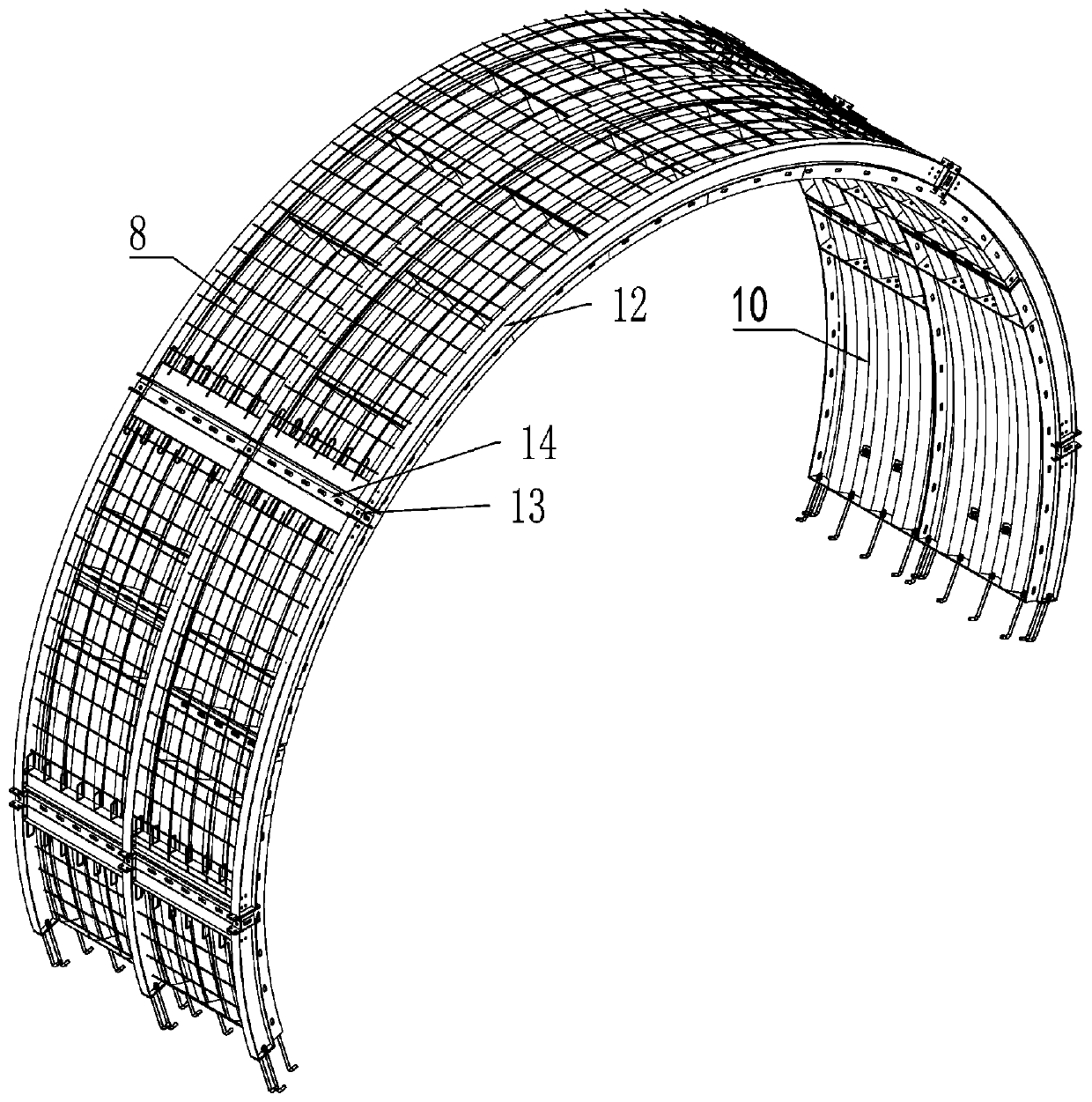

[0068] The section steel 12 is in the shape of "I", and the end of the steel mesh 8 is fixed to the web of the section steel 12; after the spraying treatment, the steel mesh 8 and the concrete form a high-strength support, and the steel mesh 8 is located in the middle of the concrete , to play a better supporting effect.

[0...

Embodiment 3

[0074] On the basis of Embodiment 2, in step S4, in the process of splicing the corrugated board 101, install a water-permeable layer 119 and a perforated water guide pipe 118 in the outer trough of the corrugated board 101, and install the water guide pipe 118 in its A heating belt 120 is worn inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com