Nozzle of straw burner

A burner and burner technology, applied in the field of components on straw burners, can solve the problems of increased equipment cost, low combustion temperature, low flame combustion temperature, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

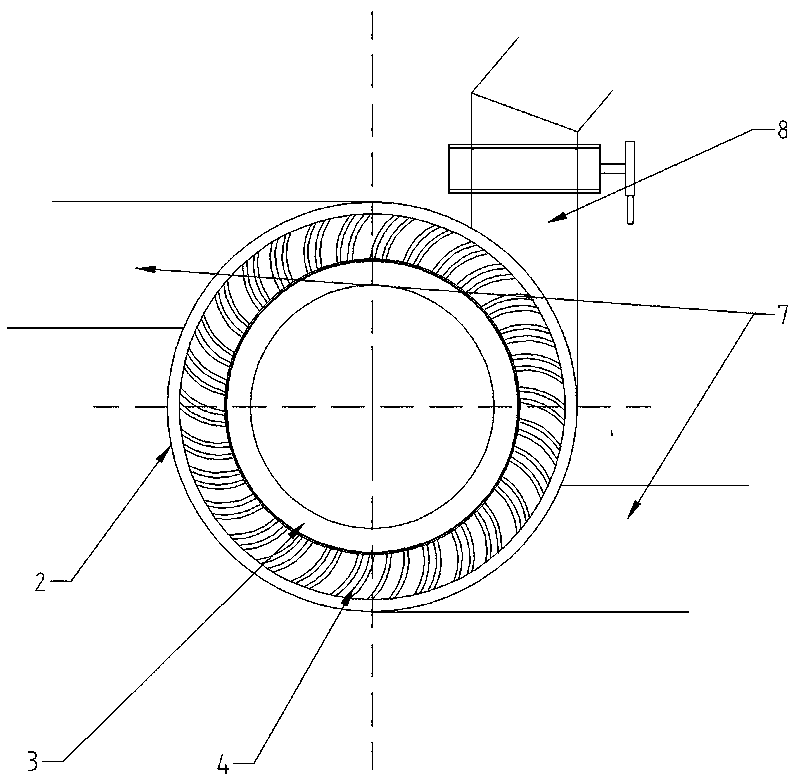

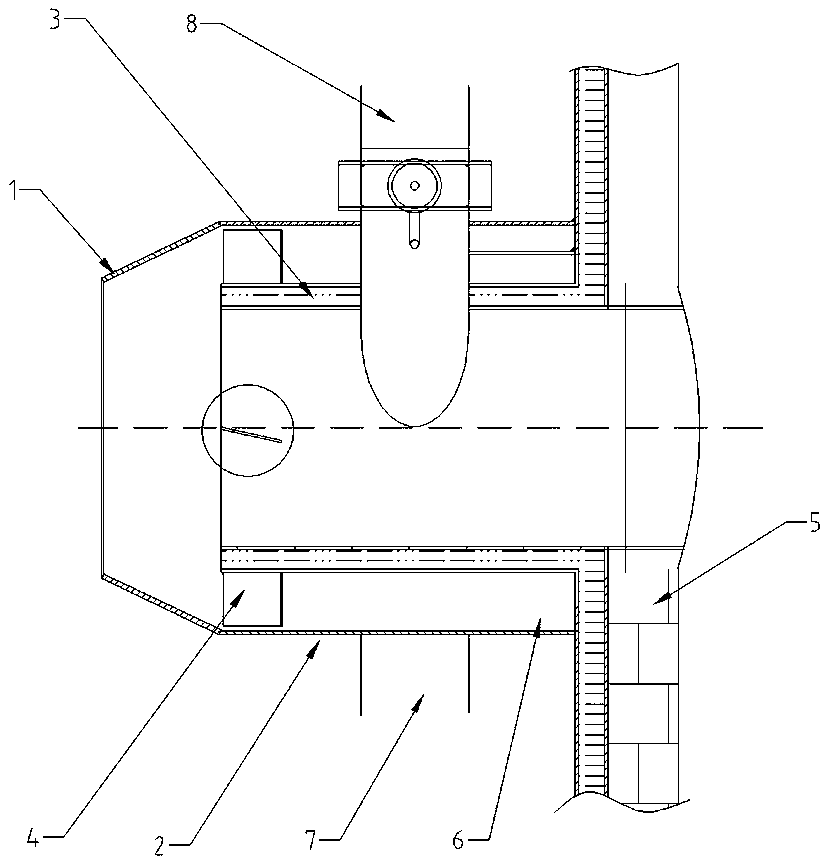

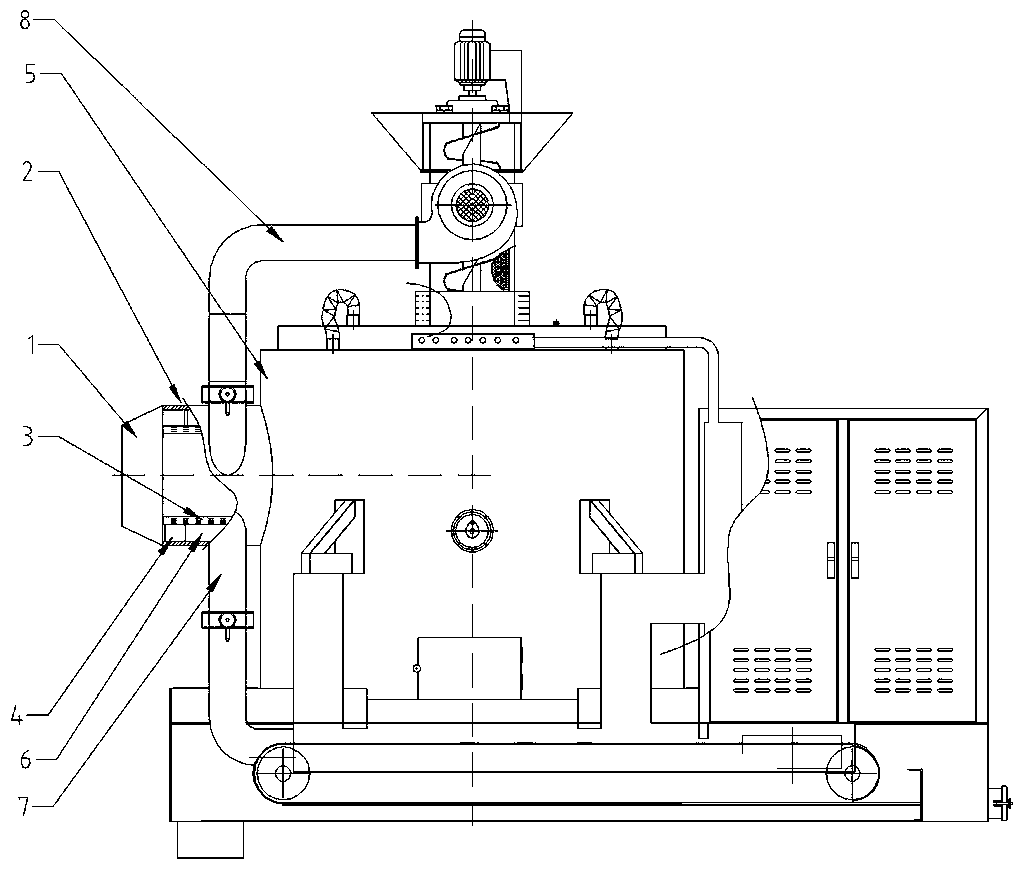

[0012] The following describes the embodiment in detail in conjunction with the accompanying drawings: This embodiment provides a plant straw particle burner, please refer to the description in the accompanying drawings Figure 1 to Figure 3 .

[0013] Such as figure 1 with image 3 As shown, a burner of a straw burner is composed of a high temperature resistant nozzle head 1, a burner outer cylinder 2 and a water jacket inner cylinder 3. The cone bottom of nozzle 1 is connected; a water jacket inner cylinder 3 is concentrically socketed inside the burner outer cylinder 2; in the annular gap between the end of the water jacket inner cylinder 3 near the high temperature resistant nozzle 1 and the burner outer cylinder 2 The cyclone deflector 4 is installed, and the other end of the water jacket inner cylinder 3 is fixed on the outer wall 5 of the upper part of the straw burner furnace and communicated with the furnace, and the inner wall of the burner outer cylinder 2, the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com