Cooling system for vehicle fuel cell system

A fuel cell system and cooling system technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of inability to control large and small cycle temperature fluctuations, inability to achieve accurate flow control, and inability to accurately control coolant flow and other issues, to achieve the effect of high-efficiency working temperature range, improving life, and reducing temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

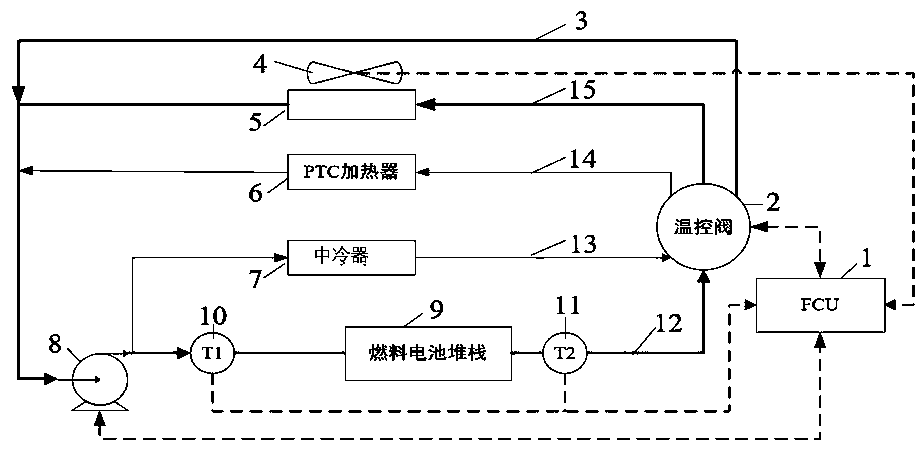

[0053] The invention aims at the deficiencies of the cooling system of the existing vehicle fuel cell system. The present invention provides a cooling system for a vehicle fuel cell system, which is used for heat dissipation of the fuel cell system. Such as figure 1As shown, the cooling system includes: a circulation pump 8; a temperature control valve 2 with five openings corresponding to five flow channels; The opening of the fuel cell control unit (FCU) 1. Among them, the first flow channel 12 connects the circulation pump 8, the fuel cell stack 9 and the first opening of the temperature control valve 2 sequentially from the upstream; the second flow channel 13 connects the circulation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com