Magnesium alloy anode sheet and preparation method thereof

A magnesium alloy and anode technology, applied in metal rolling, temperature control, elongation control, etc., can solve the problems of poor plastic deformation ability, increase the difficulty of plastic deformation of magnesium alloy, and less movable slippage, etc., and achieve stable performance, The effect of fine and uniform microstructure grains and uniform distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

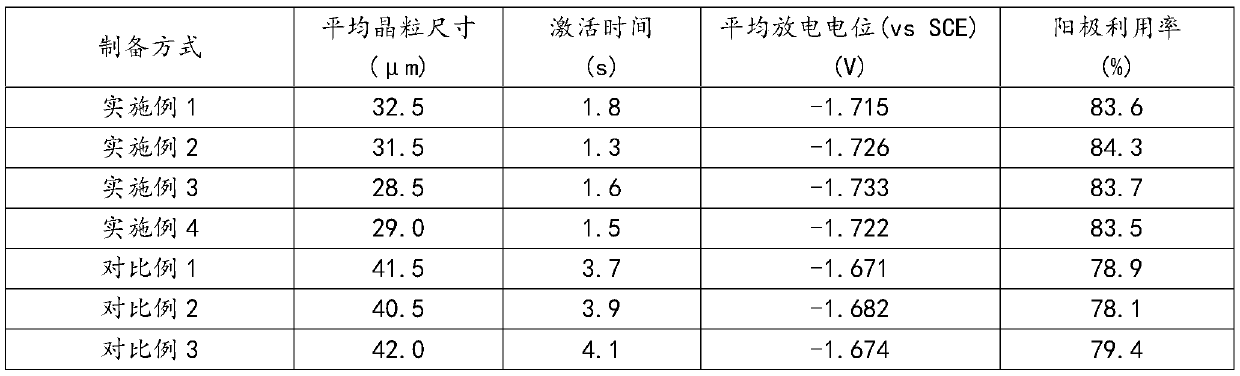

Examples

preparation example Construction

[0016] An embodiment of the present invention provides a method for preparing a magnesium alloy anode sheet, including:

[0017] S1. Extruding the semi-continuous casting annealed cast rod into an extruded plate with a thickness of 1 to 2.5 mm, with an extrusion ratio of 70 to 170.

[0018] First, the pure magnesium ingot with a magnesium content of 99.99% is heated and melted, and the temperature is raised to 700-750°C under the protection of the flux. The alloy elements are added in the form of pure metal or intermediate alloy according to the alloy composition ratio to be obtained. After refining, Stir, remove slag, and stand still. When the melt temperature is stable at 690~740℃, it is poured. The magnesium alloy casting rod is prepared by semi-continuous casting process. The cooling rate is controlled by adjusting the cooling water flow rate and temperature to obtain the semi-continuous casting. Long cast rod.

[0019] The long cast rods obtained by semi-continuous casting are ...

Embodiment 1

[0030] A magnesium alloy anode sheet provided in this embodiment includes:

[0031] The magnesium alloy semi-continuous cast rod was cut into cast rods with a length of 400mm, and homogenized annealing was carried out at a temperature of 410°C and a holding time of 22h; then the oxide layer on the surface of the cast rod was removed.

[0032] The cast rod was heated again to 280°C and held for 30 minutes, and then extruded at an extrusion ratio of 100 to form an extruded plate. The thickness of the extruded plate was 2.0 mm and the width of the extruded plate was 100 mm. The extruded plate was then slit longitudinally into 400 mm samples.

[0033] After that, the slitted extruded plate was heated to 250℃ and then kept for 40 minutes for rolling. The temperature of the roll was controlled at 200℃, and the deformation of the rolling pass was set to 20%; after each rolling pass, an intermediate annealing was carried out. The annealing temperature is 220°C, and the annealing time is 20m...

Embodiment 2

[0036] A magnesium alloy anode sheet provided in this embodiment includes:

[0037] The magnesium alloy semi-continuous cast rod was cut into cast rods with a length of 300mm, and homogenized annealing was carried out at a temperature of 320°C and a holding time of 26h; then the oxide layer on the surface of the cast rod was removed.

[0038] The cast rod was heated again to 180°C and held for 60 minutes, and then extruded at an extrusion ratio of 70 to form an extruded plate. The thickness of the extruded plate was 2.5 mm and the width of the extruded plate was 80 mm. Subsequently, the extruded plate was slit longitudinally into 400 mm samples.

[0039] After that, the slitted extruded plate is heated to 300°C and kept for 20 minutes for rolling. The temperature of the roll is controlled at 120°C, and the deformation of the rolling pass is set to 10%; intermediate annealing is performed after each rolling pass. The annealing temperature is 120°C, and the annealing time is 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com