Preparation method of flexible heating sheet and heating sheet prepared thereby

A heating sheet, flexible technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., to achieve the effects of human body heating and comfort, long service life, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing a flexible heating sheet, comprising the following steps:

[0039] (1) Dilute the silicone high-temperature adhesive with a diluent to prepare a silicone high-temperature adhesive with a glue content of 45%. The diluent is an aromatic solvent, such as toluene solution;

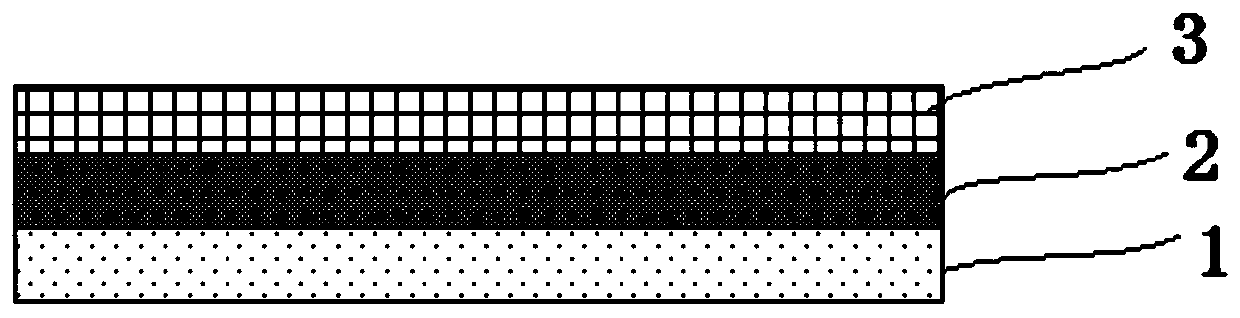

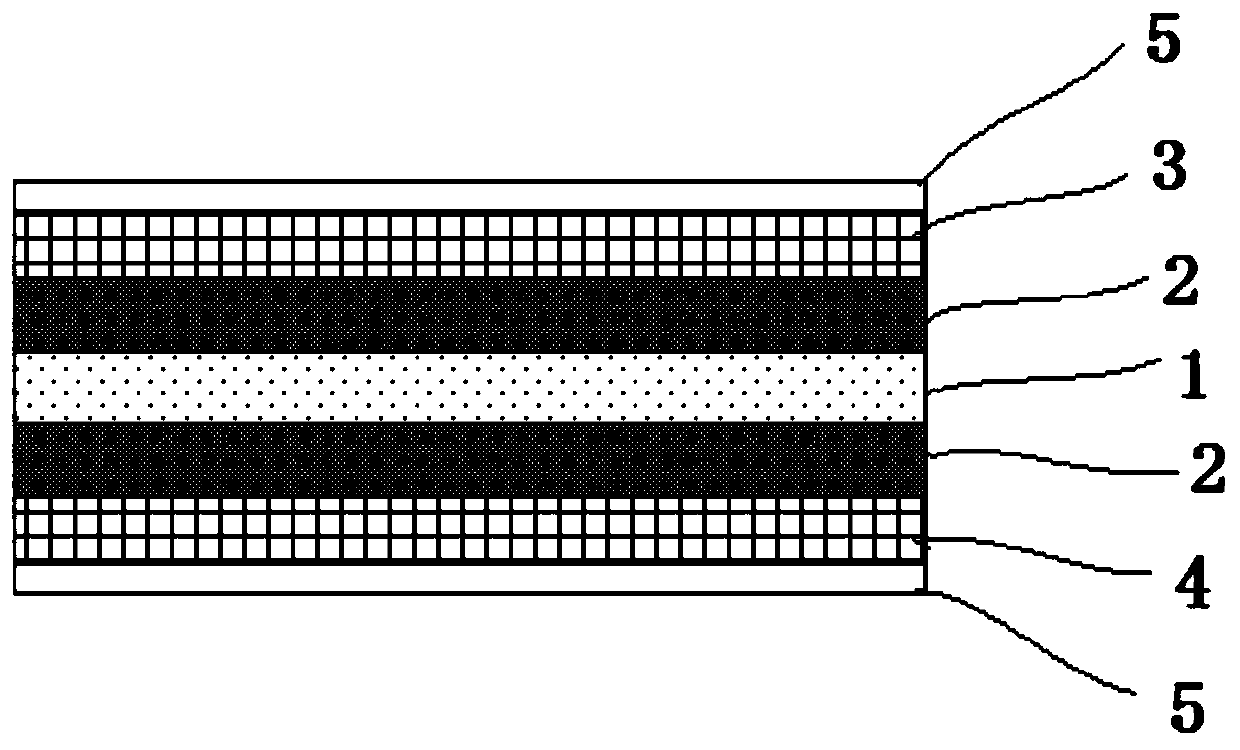

[0040] (2) Spray the silicone high-temperature adhesive diluted in step (1) on the carbon fiber heating cloth to form a silicone high-temperature adhesive layer 2, and the carbon fiber heating cloth is the carbon fiber heating cloth layer 1;

[0041] (3) Lay a layer of calcined mica paper on the organic silicon high temperature adhesive layer formed in step (2), i.e. the first mica paper layer 3, to obtain the initial product of the heating sheet;

[0042] (4) The primary product of the heating sheet obtained in step (3) is dried and compounded by a dry compound machine, and sent into a drying box at a speed of 3 / meter per second, and the temperature of the ...

Embodiment 2

[0045] This embodiment provides a method for preparing a flexible heating sheet, comprising the following steps:

[0046] (1) Dilute the silicone high-temperature adhesive with a diluent to prepare a silicone high-temperature adhesive with a glue content of 15%. The diluent is an aromatic solvent, such as xylene solution;

[0047] (2) Spray the silicone high-temperature adhesive diluted in step (1) on the carbon fiber heating cloth to form a silicone high-temperature adhesive layer;

[0048] (3) spreading a layer of calcined mica paper on the organic silicon high-temperature adhesive layer formed in step (2), to obtain the initial product of the heating sheet;

[0049] (4) Dry and compound the initial product of the heating sheet obtained in step (3) through a dry compound machine, and send it into the drying box at a speed of 3 / meter per second, adjust the temperature of the drying box to 65 ° C, and keep it warm for 2 minutes ; After that, adjust the temperature of the dryi...

Embodiment 3

[0052] This embodiment provides a method for preparing a flexible heating sheet, comprising the following steps:

[0053] (1) Dilute the silicone high-temperature adhesive with a diluent to prepare a silicone high-temperature adhesive with a glue content of 20%;

[0054] (2) Spray the silicone high-temperature adhesive diluted in step (1) on the carbon fiber heating cloth to form a silicone high-temperature adhesive layer;

[0055] (3) spreading a layer of calcined mica paper on the organic silicon high-temperature adhesive layer formed in step (2), to obtain the initial product of the heating sheet;

[0056] (4) The primary product of the heating sheet obtained in step (3) is dried and compounded by a dry compound machine, and sent into a drying box at a speed of 3 / meter per second, and the temperature of the drying box is adjusted to 60 ° C, and the temperature is kept for 2 minutes ; After that, adjust the temperature of the drying box to 120°C and keep it warm for 2 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com