Degradable random copolymerization BOPP composition and application thereof

A technology of random copolymerization and composition, applied in flexible covering, packaging, wrapping paper, etc., can solve the problems of poor degradation performance and high rigidity of cigarette film, and achieve fast crystallization speed, good biocompatibility, and good synergy. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

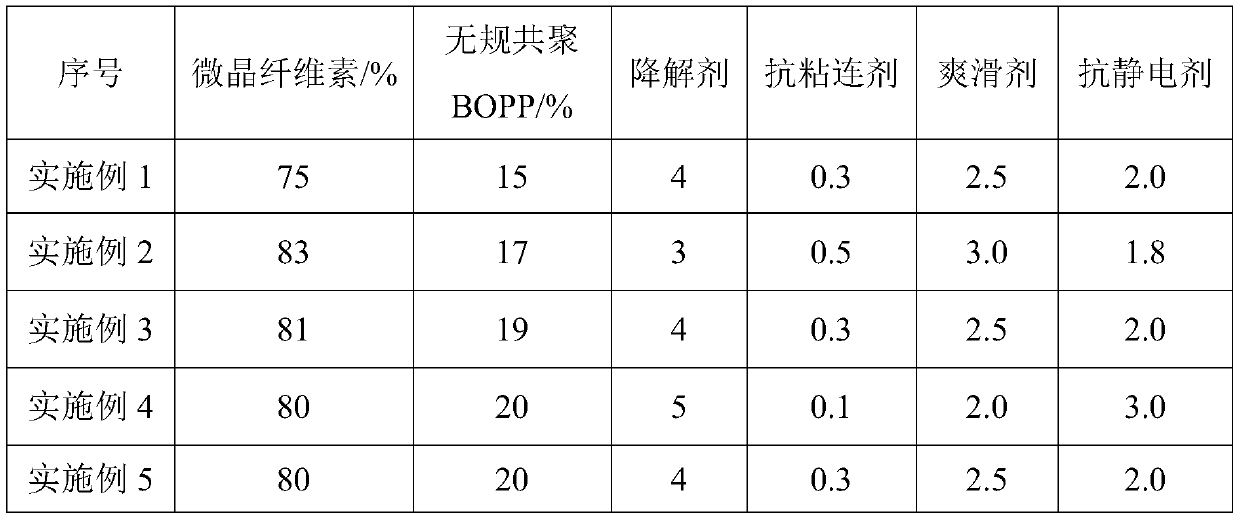

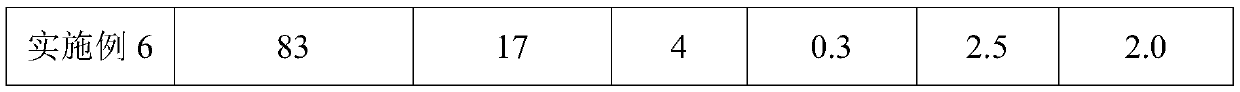

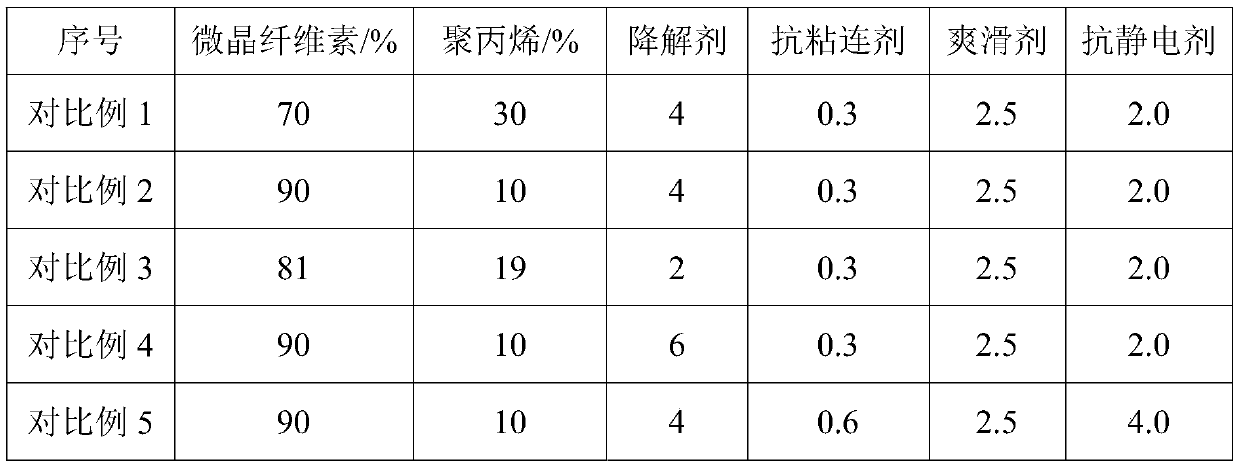

[0029] A degradable random copolymerized BOPP composition prepared from the components in parts by mass shown in Table 1, wherein 100 parts of microcrystalline cellulose and propylene / ethylene-1 random copolymerized BOPP.

[0030] Table 1 Random copolymerization BOPP composition component

[0031]

[0032]

[0033] Wherein the smooth agent is silicone, and the antistatic agent is glycerol monostearate.

Embodiment 7

[0035] A random copolymerized BOPP composition prepared from the components in parts by mass of Example 1, the difference being that the haze of the propylene / ethylene-1 random copolymerized BOPP is 0.8%.

Embodiment 8

[0037] A random copolymerized BOPP composition prepared from the components in parts by mass of Example 1, the difference being that the haze of the propylene / ethylene-1 random copolymerized BOPP is 1.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| isotactic index | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com