A thick gauge 450hb wear-resistant steel plate with a large reduction and its rolling method

A wear-resistant steel plate and high reduction technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive effects, inconspicuous effects, etc. Efficiency has little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

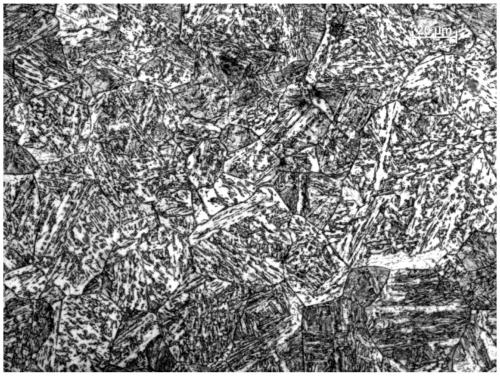

[0034] A thick gauge 450HB grade wear-resistant steel plate with a large reduction. The chemical composition and weight percentage (%) of the steel plate are: C: 0.19%, Si: 0.28%, Mn: 0.96%, Al≤0.055%, Nb: 0.02%, Ti: 0.018%, Ni: 0.49%, Cr: 1.13%, Mo: 0.32%, V: 0.03%, the rest is Fe and trace impurities;

[0035] Among them, Ni, Cr, and Mo elements are added separately;

[0036] The thickness of the steel plate is 100mm.

[0037] The rolling method of the wear-resistant steel plate comprises the following steps:

[0038] (1) The cross-sectional size of molten iron is 300*2200mm after KR pretreatment, 120-ton top-bottom combined blowing converter smelting, 120-ton LF ladle furnace refining, 120-ton RH vacuum degassing refining and slab continuous casting machine, etc. Slow cooling of stacks;

[0039] (2) Evenly heat the blank in the heating furnace, the heating time is controlled according to 11min / cm, and the temperature of the furnace is controlled at 1230°C;

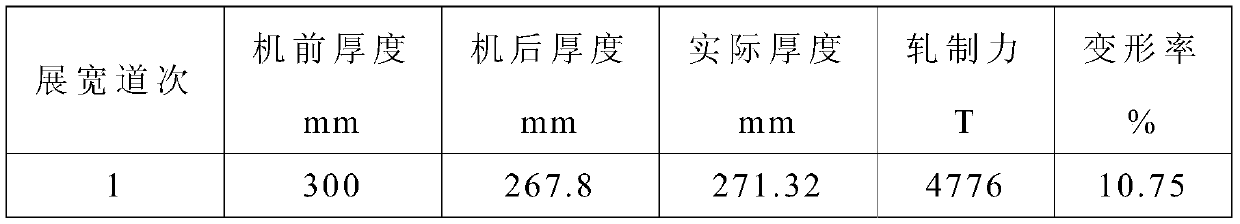

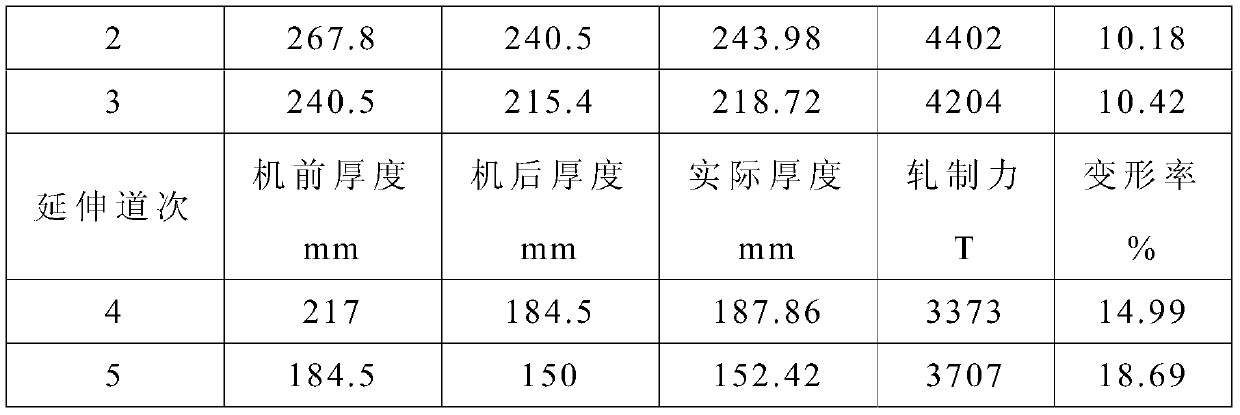

[0040] (3) ...

Embodiment 2

[0053] A thick gauge 450HB grade wear-resistant steel plate with a large reduction. The chemical composition and weight percentage content (%) of the steel plate are: C: 0.33%, Si: 0.28%, Mn: 1.05%, Al≤0.055%, Nb: 0.02%, Ti: 0.025%, Ni: 0.50%, Cr: 1.20%, Mo: 0.37%, V: 0.03%, the rest is Fe and trace impurities;

[0054] Among them, Ni, Cr, and Mo elements are added separately;

[0055] The thickness of the steel plate is 75mm.

[0056] The rolling method of the wear-resistant steel plate comprises the following steps:

[0057] (1) Select a blank of smelted 450HB grade wear-resistant steel plate, the thickness of which is 250mm, and stack and slowly cool;

[0058] (2) Evenly heat the blank in the heating furnace, the heating time is controlled according to 11min / cm, and the temperature of the furnace is controlled at 1210°C;

[0059] (3) Expanding along the width direction of the billet in 2 passes, rolling with a large reduction of 25mm, and controlling the rolling speed to...

Embodiment 3

[0066] A thick gauge 450HB grade wear-resistant steel plate with a large reduction. The chemical composition and weight percentage content (%) of the steel plate are: C: 0.22%, Si: 0.37%, Mn: 1.05%, Al≤0.055%, Nb: 0.04%, Ti: 0.026%, Ni: 0.53%, Cr: 1.24%, Mo: 0.36%, V: 0.04%, the rest is Fe and trace impurities;

[0067] Among them, Ni, Cr, and Mo elements are added in combination;

[0068] The thickness of the steel plate is 80mm.

[0069] The rolling method of the wear-resistant steel plate comprises the following steps:

[0070] (1) Select a blank of smelted 450HB grade wear-resistant steel plate, the thickness of which is 265mm, and stack and slowly cool;

[0071] (2) Evenly heat the blank in the heating furnace, the heating time is controlled according to 11min / cm, and the temperature of the furnace is controlled at 1220°C;

[0072] (3) Expanding along the width direction of the billet in 2 passes, rolling with a large reduction of 25mm, and controlling the rolling spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com