Etchant for observation and energy spectrum analysis of sigma phase through scanning electron microscope and using method thereof

An electron microscope and energy spectrum analysis technology, which is applied in the field of etchant, can solve the problems of inability to detect and analyze the σ phase composition and affect the work of failure analysis, and achieve the effect of pollution-free erosion, simple composition and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

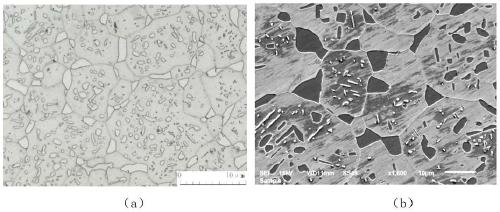

Embodiment 1

[0036] Take 2g of copper sulfate pentahydrate as raw materials, 8g of sodium chloride, 20g of phosphoric acid, 1g of absolute ethanol, and 20g of distilled water. The purity grades of the copper sulfate pentahydrate, sodium chloride, phosphoric acid and absolute ethanol are analytically pure.

[0037] (1) Preparation of etchant: Put copper sulfate pentahydrate and sodium chloride in the container, then add distilled water and stir for 10 minutes, then add phosphoric acid and absolute ethanol, continue to stir for 20 minutes, and then let stand for 20 minutes to obtain the etching agent. etchant;

[0038] (2) Etching: Take the aging and invalid S31008 stainless steel as a sample, grind and polish the sample to be etched, and then immerse it in the etchant. During the etching process, use cotton to wipe the polished surface of the sample for 5 seconds. Take it out after light gray, rinse with water and then with absolute ethanol, and then dry it with hot air or dry it, then use...

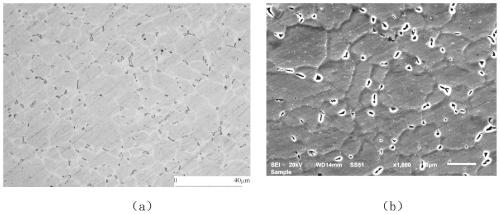

Embodiment 2

[0043] Take 5 g of copper sulfate pentahydrate as raw materials, 12 g of sodium chloride, 30 g of phosphoric acid, 2 g of absolute ethanol, and 50 g of distilled water. The purity grades of the copper sulfate pentahydrate, sodium chloride, phosphoric acid and absolute ethanol are analytically pure.

[0044] (1) Preparation of etchant: Put copper sulfate pentahydrate and sodium chloride in the container, then add distilled water and stir for 10 minutes, then add phosphoric acid and absolute ethanol, continue to stir for 20 minutes, and then let stand for 20 minutes to obtain the etching agent. etchant;

[0045] (2) Etching: Take the aging and invalid 06Cr19Ni10 stainless steel as a sample, grind and polish the sample to be etched, and then immerse it in the etchant. During the etching process, use cotton to wipe the polished surface of the sample for 15 seconds. Take it out after light gray, rinse with water and then with absolute ethanol, and then dry it with hot air or dry i...

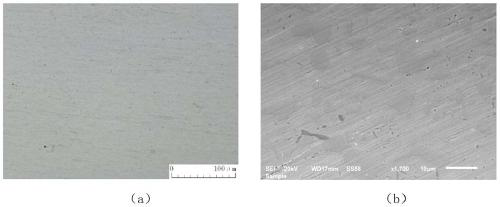

Embodiment 3

[0050] Take 10 g of copper sulfate pentahydrate as raw materials, 18 g of sodium chloride, 40 g of phosphoric acid, 4 g of absolute ethanol, and 70 g of distilled water. The purity grades of the copper sulfate pentahydrate, sodium chloride, phosphoric acid and absolute ethanol are analytically pure.

[0051] (1) Preparation of etchant: Put copper sulfate pentahydrate and sodium chloride in the container, then add distilled water and stir for 10 minutes, then add phosphoric acid and absolute ethanol, continue to stir for 20 minutes, and then let stand for 20 minutes to obtain the etching agent. etchant;

[0052] (2) Etching: Take aging and invalid TP347HFG stainless steel as a sample, grind and polish the sample to be etched, and then immerse it in the etchant. During the etching process, use cotton to wipe the polished surface of the sample for 20 seconds. Take it out after light gray, rinse with water and then with absolute ethanol, and then dry it with hot air or dry it, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com