Gas stove control method based on pressing type rotary knob

A control method and technology for gas stoves, applied in the field of gas stoves, can solve problems such as reduced convenience experience, reduced safety, fire occurrence, etc., and achieve the advantages of reducing unnecessary gas air-burning time, improving operation convenience, and reducing mechanical wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

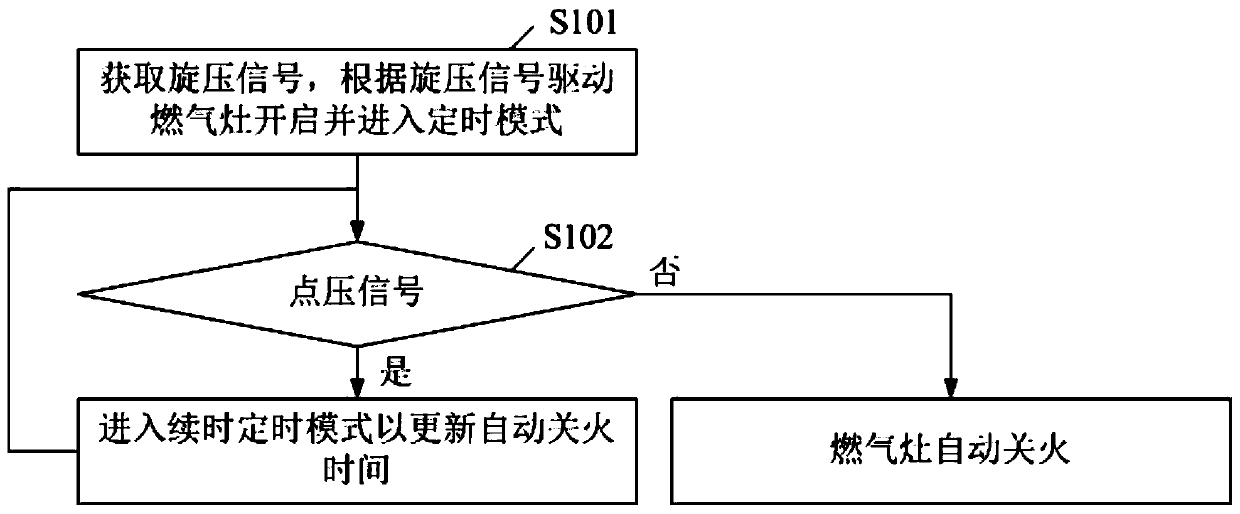

[0048] see figure 1 , figure 1 It shows the flow chart of the first embodiment of the gas stove control method based on the push knob of the present invention, which includes:

[0049] S101. Obtain a spinning signal, and drive the gas stove to turn on and enter a timing mode according to the spinning signal.

[0050] In this embodiment, the timing mode is a point pressing continuous time mode.

[0051] S102. In the point pressure continuation mode, if the controller acquires the point pressure signal, enter the continuation timing mode to update the automatic fire-off time.

[0052] For example, if the preset time of the press-on-time mode is 6 minutes, the automatic fire-off time needs to be updated to 10 minutes. In the state of releasing the electronic child lock, press the knob counterclockwise and cross the self-locking limit position of the cock valve, the gas stove will ignite immediately and start to burn. At this time, the gas stove enters the continuous pressure m...

no. 2 example

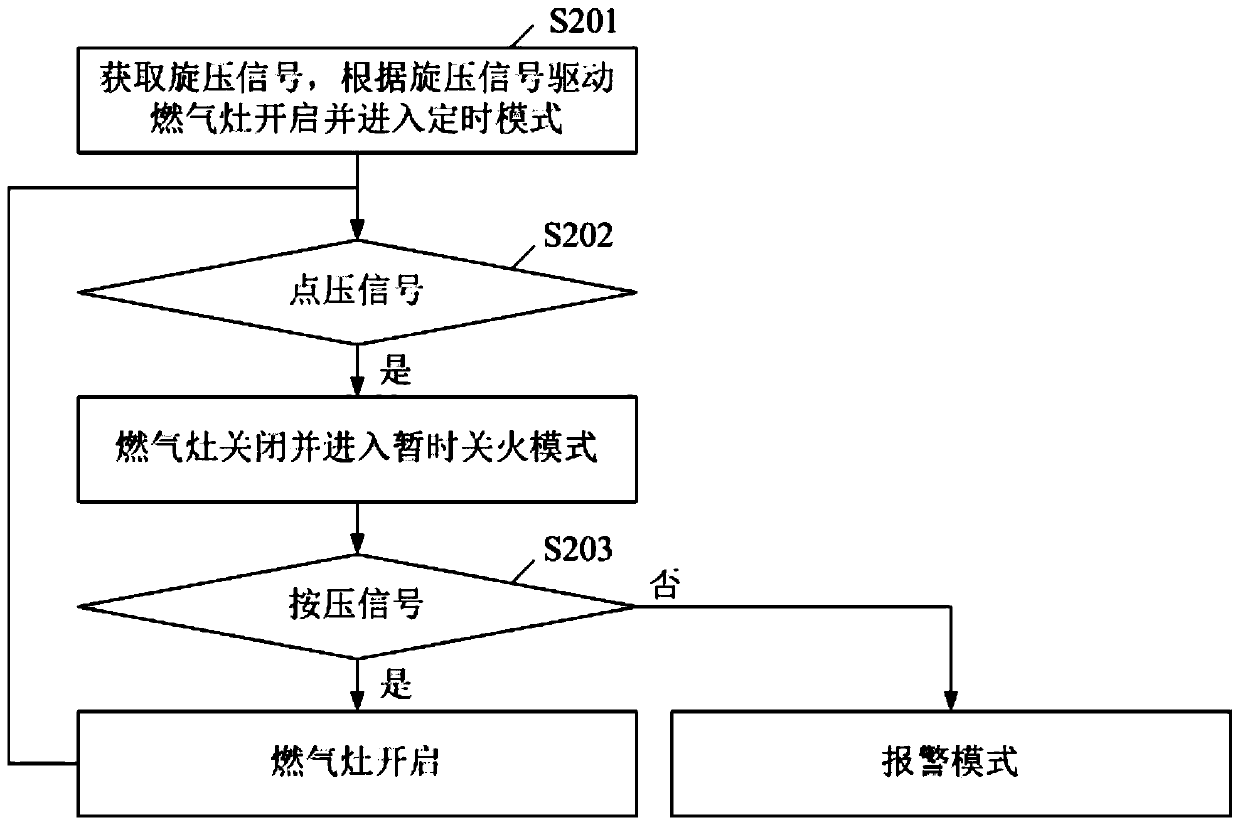

[0055] see figure 2 , figure 2 It shows the flow chart of the second embodiment of the gas stove control method based on the push knob of the present invention, which includes:

[0056] S201. Obtain a spinning signal, and drive the gas stove to turn on and enter a timing mode according to the spinning signal.

[0057] In this embodiment, the timing mode is a pressure-on-fire-off mode.

[0058] S202. In the ignition-off mode with pressure, if a pressure signal is obtained, the gas stove is turned off and enters a temporary ignition-off mode.

[0059] S203. In the temporary fire-off mode, if a pressing signal is obtained, the gas stove is turned on and enters the point-press fire-off mode, otherwise, enters an alarm mode.

[0060] For example, if the preset time of the click-to-fire mode is 6 minutes and the preset time of the temporary fire-off mode is 10 minutes. In the state of releasing the electronic child lock, press the knob counterclockwise and cross the self-locki...

no. 3 example

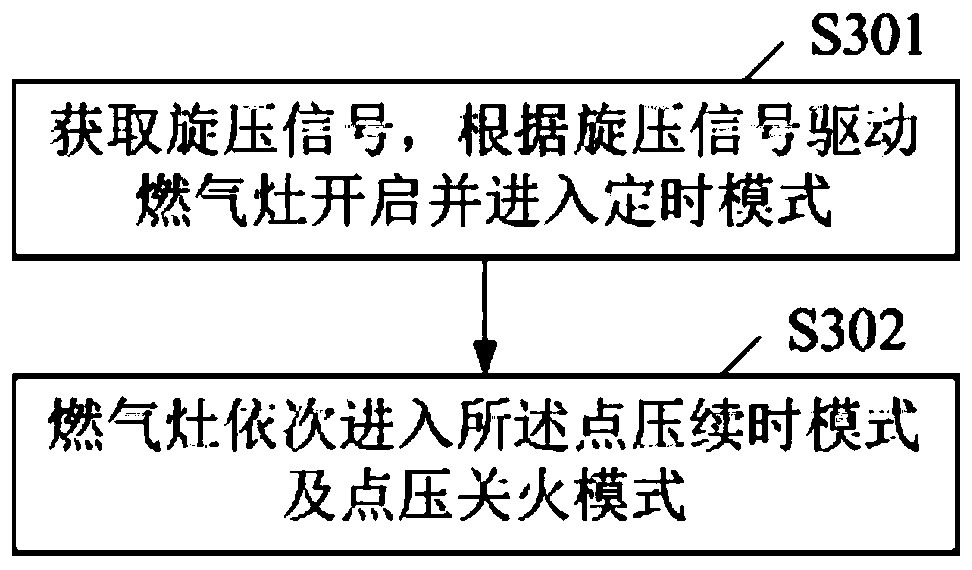

[0063] see image 3 , image 3 It shows the flow chart of the third embodiment of the gas stove control method based on the push knob of the present invention, which includes:

[0064] S301. Obtain a spinning signal, and drive the gas stove to turn on and enter a timing mode according to the spinning signal.

[0065] In this embodiment, the timing mode is a continuous-fire-off mode;

[0066] S302. In the continuation-fire-off mode, the gas cooker sequentially enters the pressure-on-time mode and the pressure-off mode.

[0067] For example, if the preset time of the click-on-time mode is 2 minutes, the preset time of the click-off fire mode is 5 minutes. In the state of releasing the electronic child lock, press the knob counterclockwise and cross the self-locking limit position of the cock valve, the gas stove will ignite immediately and start to burn. At this time, the gas stove enters the continuous pressure mode; Within 2 minutes, if no pressure signal is received, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com