Vacuum pump vibration signal noise reduction method based on EEMD (ensemble empirical mode decomposition) and wavelet threshold

A technology of vibration signal and wavelet threshold value, which is applied in character and pattern recognition, measurement of ultrasonic/sonic wave/infrasonic wave, measuring device, etc., can solve problems affecting noise reduction effect, improve signal-to-noise ratio, remove noise signal, reduce The effect of root mean square error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

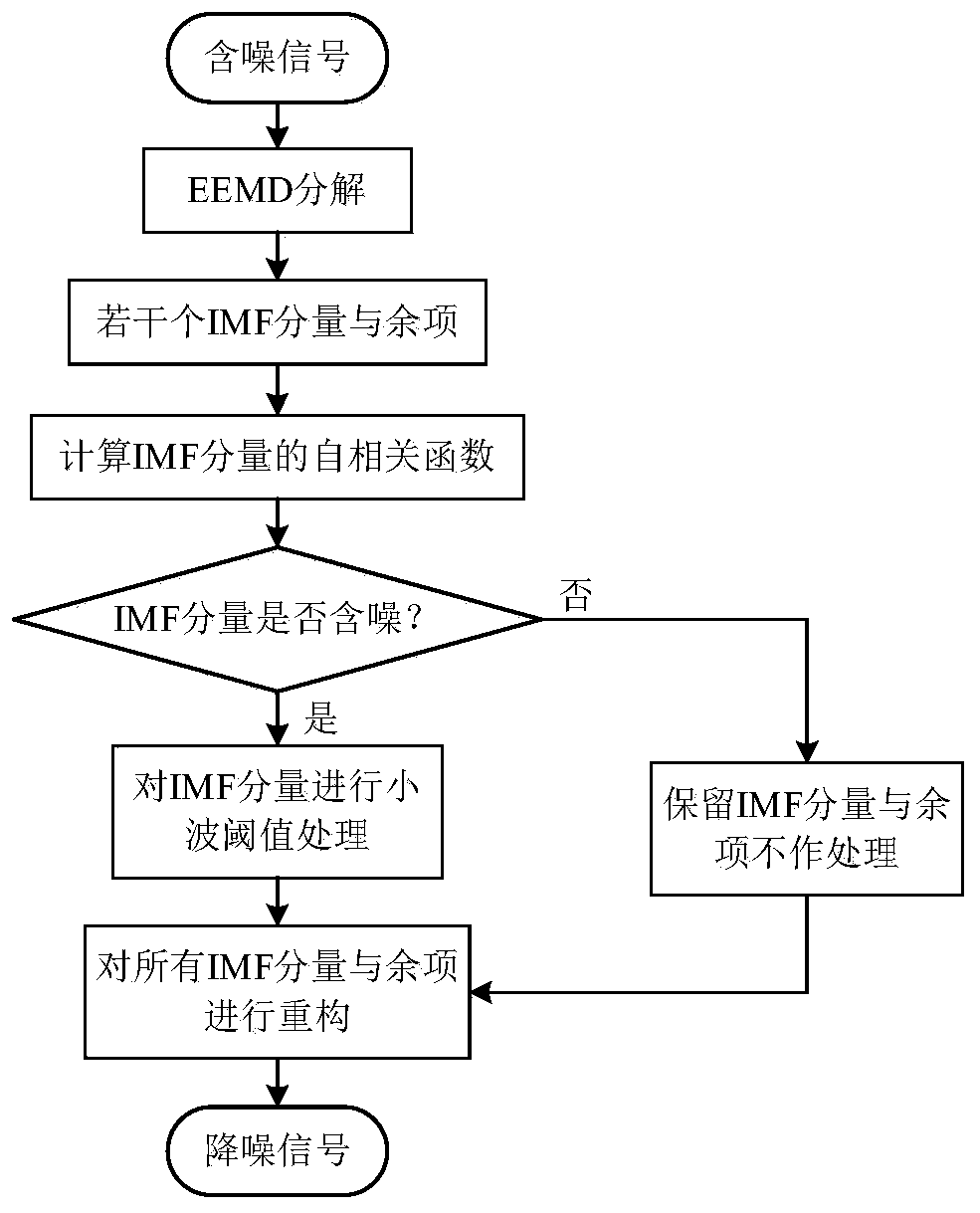

Method used

Image

Examples

Embodiment 1

[0102] The simulation analysis of the above vacuum pump vibration signal noise reduction method based on EEMD and wavelet threshold value is carried out: the mathematical model of the original signal and its noise signal is established, and the Blocks wave commonly used in MATLAB noise reduction experiments is used as the simulation signal. Gaussian white noise with a signal-to-noise ratio of 8.2955dB is added to the Blocks wave, the signal sampling rate is 1Hz, and the number of sampling points is set to 1024, as Figure 3a and 3b As shown, it is the simulated Blocks signal and its noise-added signal: where, Figure 3a is the original Blocks signal, Figure 3b is the noisy Blocks signal.

[0103] Perform EEMD decomposition on the noise-added Blocks signal (the number of decompositions M is 150, and the standard deviation k of white noise is 0.5), and a total of 9 IMF components and 1 remainder are obtained, as Figures 4a to 4jShown is the result of EEMD decomposition of t...

Embodiment 2

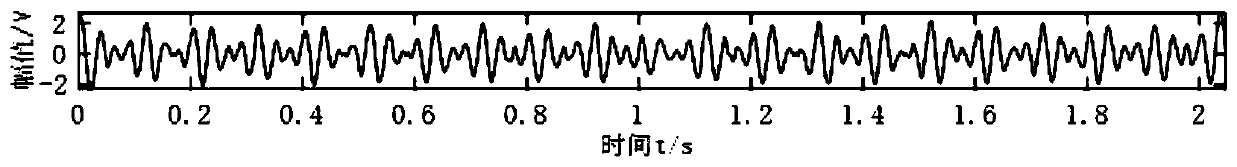

[0113] An example analysis of the above vacuum pump vibration signal noise reduction method based on EEMD and wavelet threshold value is carried out: the noise reduction method proposed by the present invention is applied to the noise reduction processing of a certain type of vacuum pump vibration data signal. The data acquisition system consists of host computer, NI-USB 6366 data acquisition card, pre-charge amplifier and acoustic emission sensor. In the experiment, the center of the vacuum pump casing is used as the vibration signal collection point for real-time data collection. By setting the sampling rate to 100kHz and the sampling time to 0.5s, the data sampling of the vibration signal of the vacuum pump is performed. The original vibration signal of the vacuum pump is as follows: Figure 7 shown.

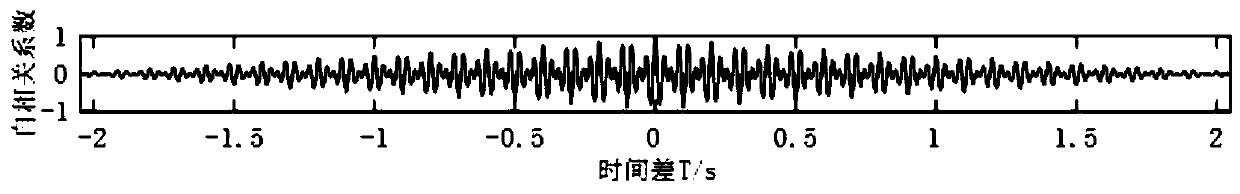

[0114] The denoising method based on EEMD and wavelet threshold is used to denoise the noisy vibration signal. After the noise-containing signal is decomposed by EEMD, a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com