A pcb rogowski coil for measuring the chip current of crimping igbt module

A technology of Rogowski coils and measuring coils, which is applied in the directions of measuring current/voltage, measuring electrical variables, transformer/inductor coils/windings/connections, etc. It can solve the problem of only measuring distribution at the edge, chip current cannot be measured, and increasing current Measurement cost and other issues, to achieve the effect of ensuring the accuracy of current measurement, facilitating research, and eliminating electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

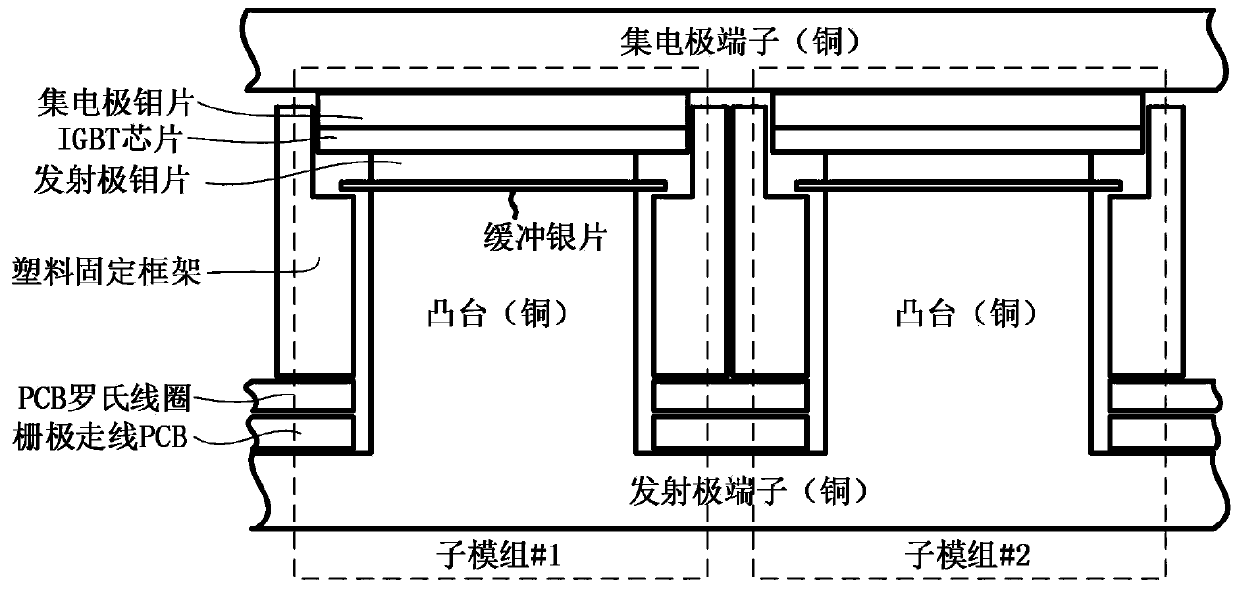

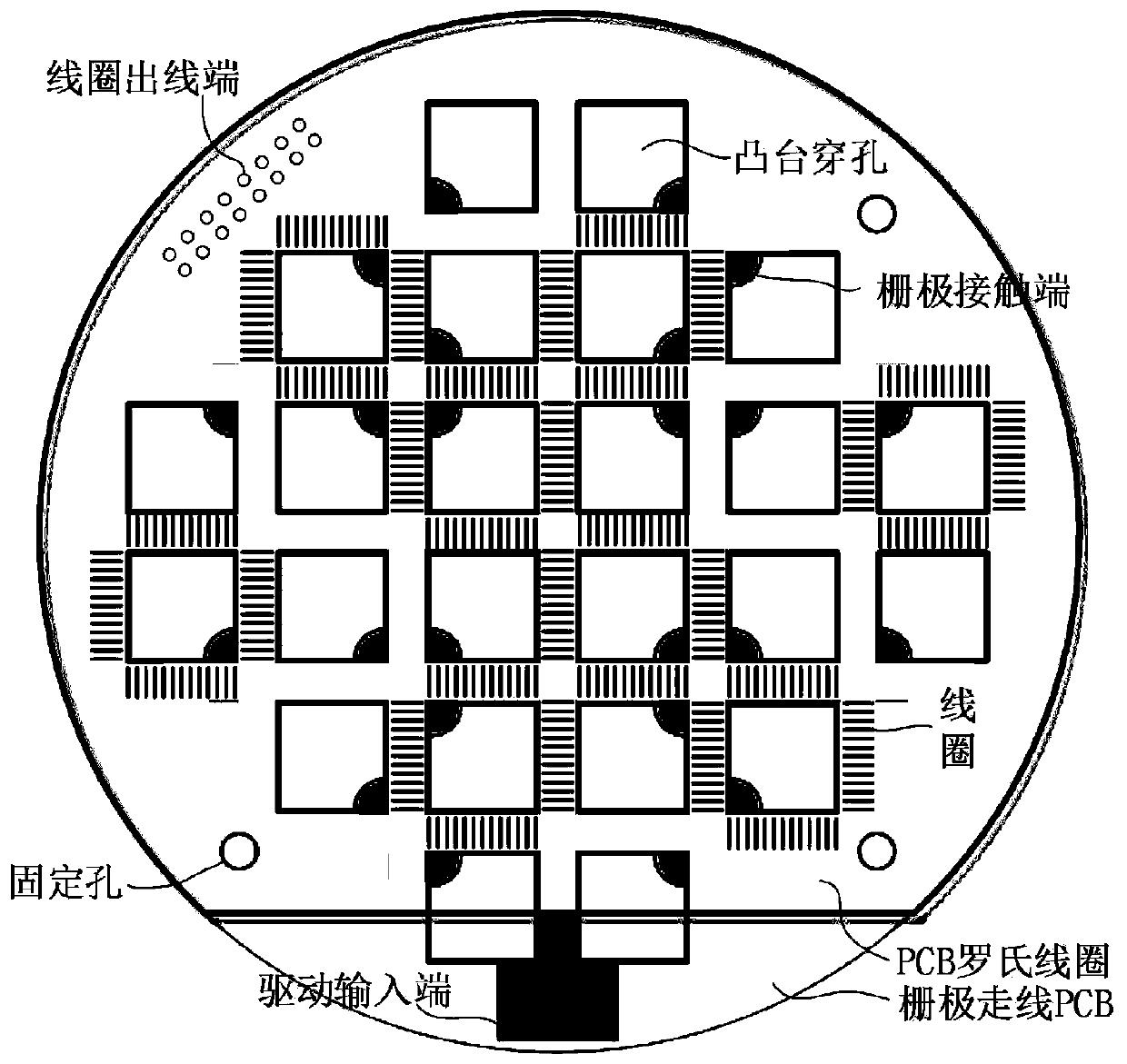

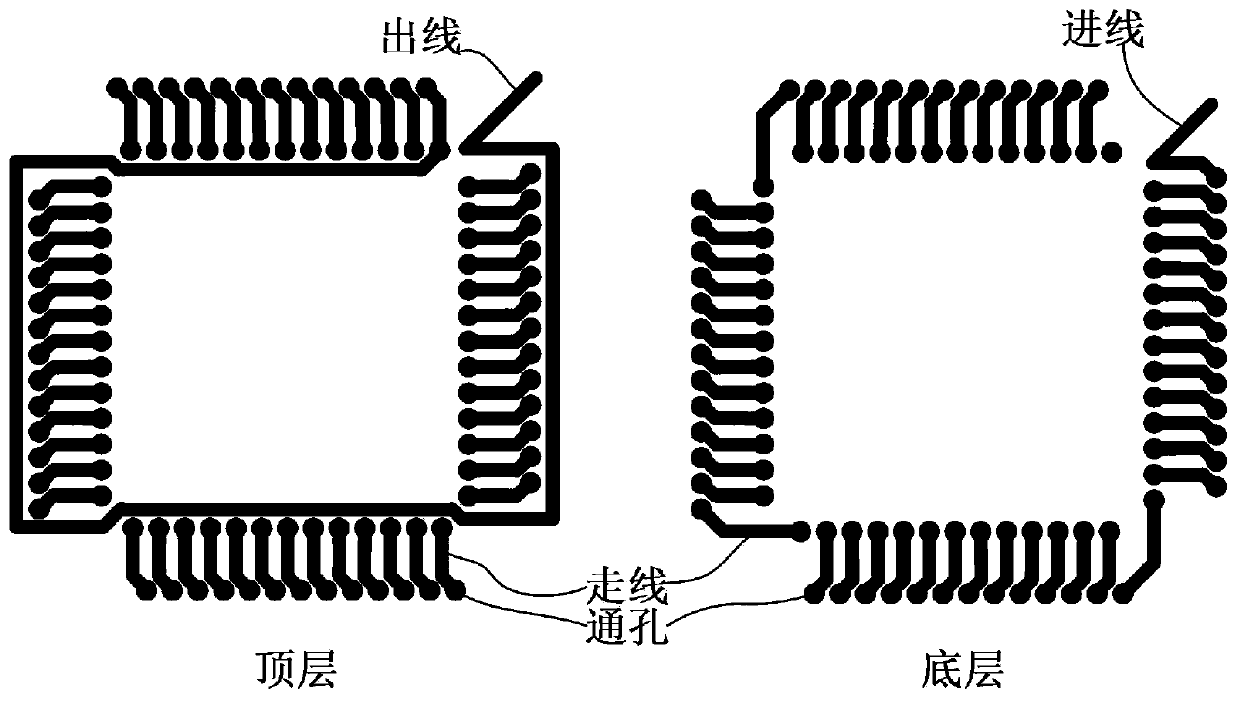

[0029] The collector molybdenum sheet, IGBT chip, emitter molybdenum sheet, silver sheet boss and plastic fixing frame in the crimping IGBT module are collectively referred to as sub-modules as a subunit. figure 1 A cross-sectional view of two sub-modules of a crimped IGBT module is shown. The upper and lower layers of molybdenum sheets can maintain uniform contact pressure on both sides and reduce the thermal expansion of the IGBT chip at high temperature, and as a good conductor of electricity and heat, it can conduct current and device loss well. The buffer silver sheet can well alleviate the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com