Modeling method and system for stockyard materials based on 3D laser scanning

A technology of three-dimensional laser and modeling method, which is applied in the field of three-dimensional laser scanning, can solve the problems of mechanical empty running, wear and tear, and low operating efficiency, and achieve the effect of avoiding interference, high-precision scanning, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Modeling method of stockyard materials based on 3D laser scanning

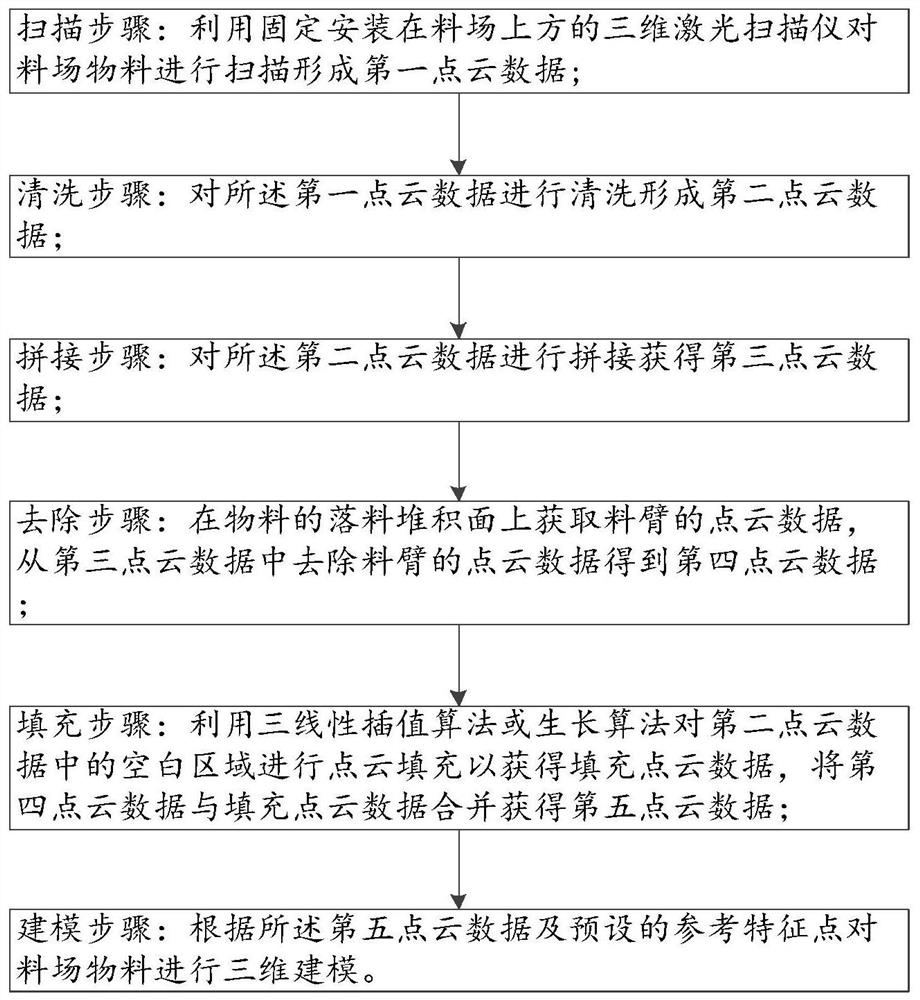

[0066] Such as figure 1 as shown, figure 1 A schematic flow chart of a modeling method for stockyard materials based on three-dimensional laser scanning provided in an embodiment of the present invention, the modeling method for stockyard materials includes the following steps:

[0067] Scanning steps: Use a 3D laser scanner fixedly installed above the stockyard to scan the stockyard materials to form the first point cloud data,

[0068] Cleaning step: cleaning the first point cloud data to form second point cloud data;

[0069] Stitching step: splicing the second point cloud data to obtain the third point cloud data;

[0070] Removal step: Obtain the point cloud data of the material arm on the blanking accumulation surface of the material, remove the point cloud data of the material arm from the third point cloud data to obtain the fourth point cloud data;

[0071] Filling step: use the trilinea...

Embodiment 2

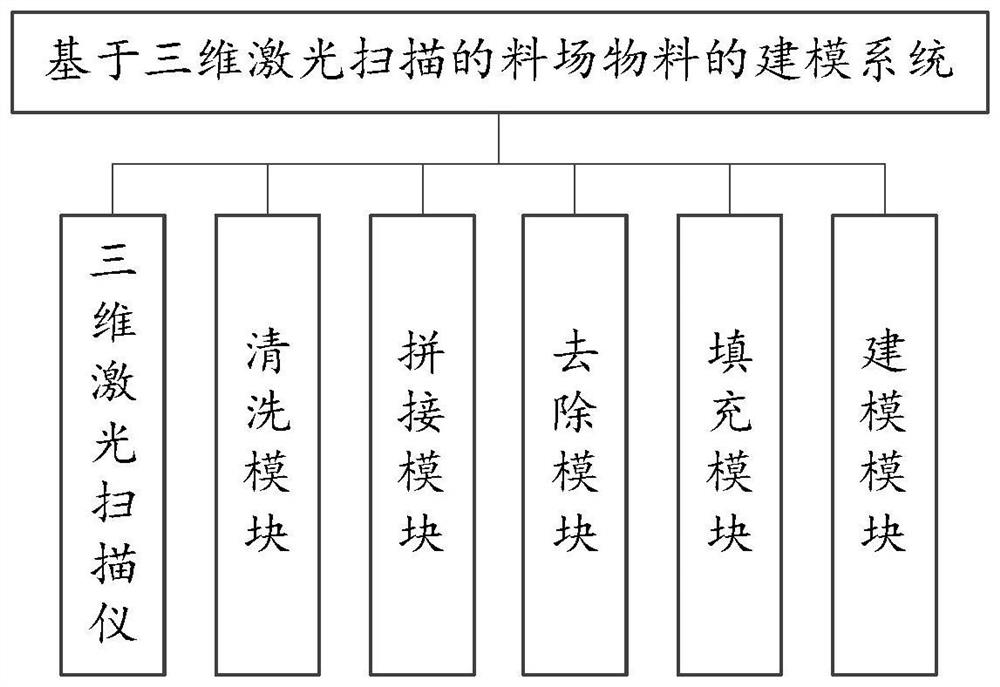

[0116] A specific implementation of a modeling system for a stockyard based on three-dimensional laser scanning provided by the present invention is introduced below.

[0117] Such as figure 2 As shown, it is a schematic structural diagram of a modeling system based on three-dimensional laser scanning provided by an embodiment of the present invention; the modeling system includes a three-dimensional laser scanner, a cleaning module, a splicing module, a removal module, a filling module and modeling module;

[0118] Use the 3D laser scanner fixedly installed above the stockyard to scan the stockyard materials to form the first point cloud data;

[0119] The cleaning module is used to clean the first point cloud data to form second point cloud data;

[0120] The splicing module is used to splice the second point cloud data to obtain the third point cloud data;

[0121] The three-dimensional laser scanner acquires the point cloud data of the material arm on the blanking and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com