High-bandwidth two-freedom-degree parallel flexible precision positioning platform

A precise positioning, high-bandwidth technology, applied in the parts and instruments of the instrument, can solve problems such as difficulty in preloading, and achieve the effects of improving connection stiffness, reducing coupling error, and large preloading force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the present invention will be further elaborated below in conjunction with the accompanying drawings.

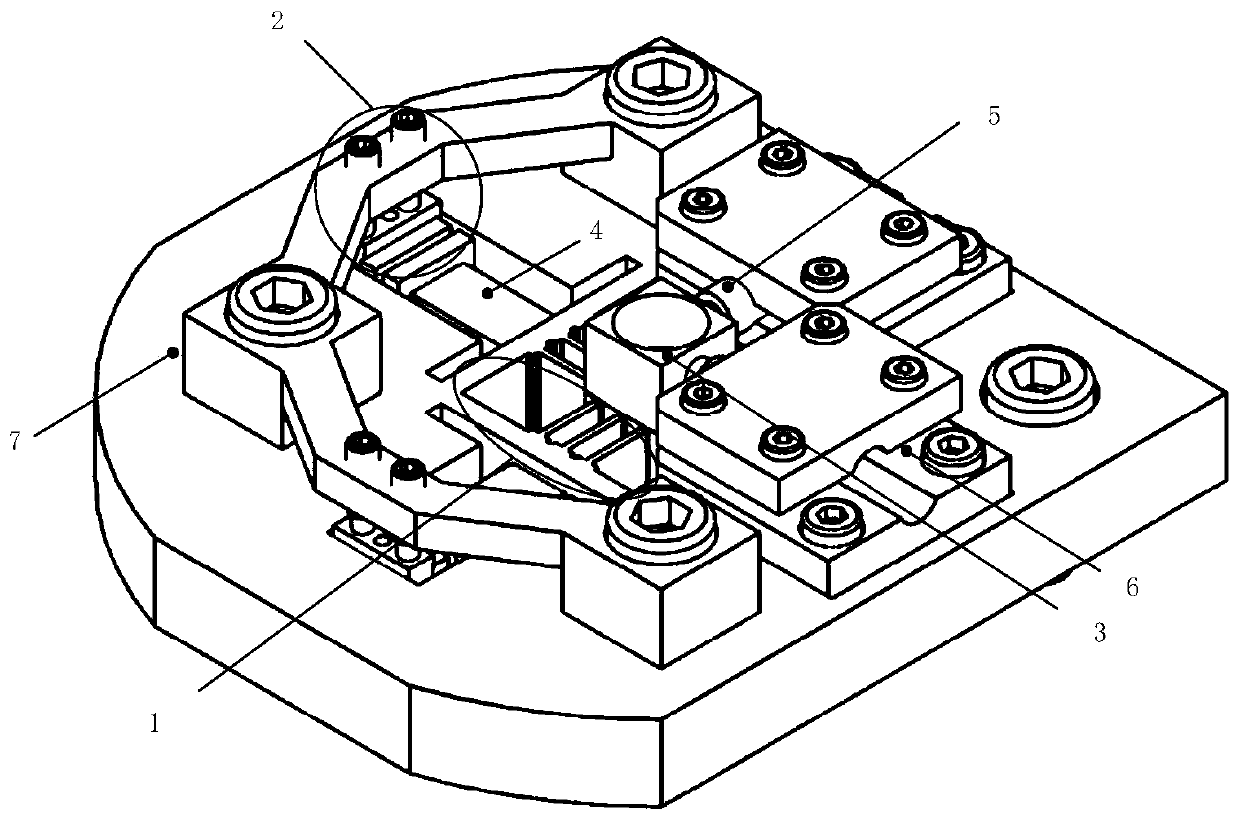

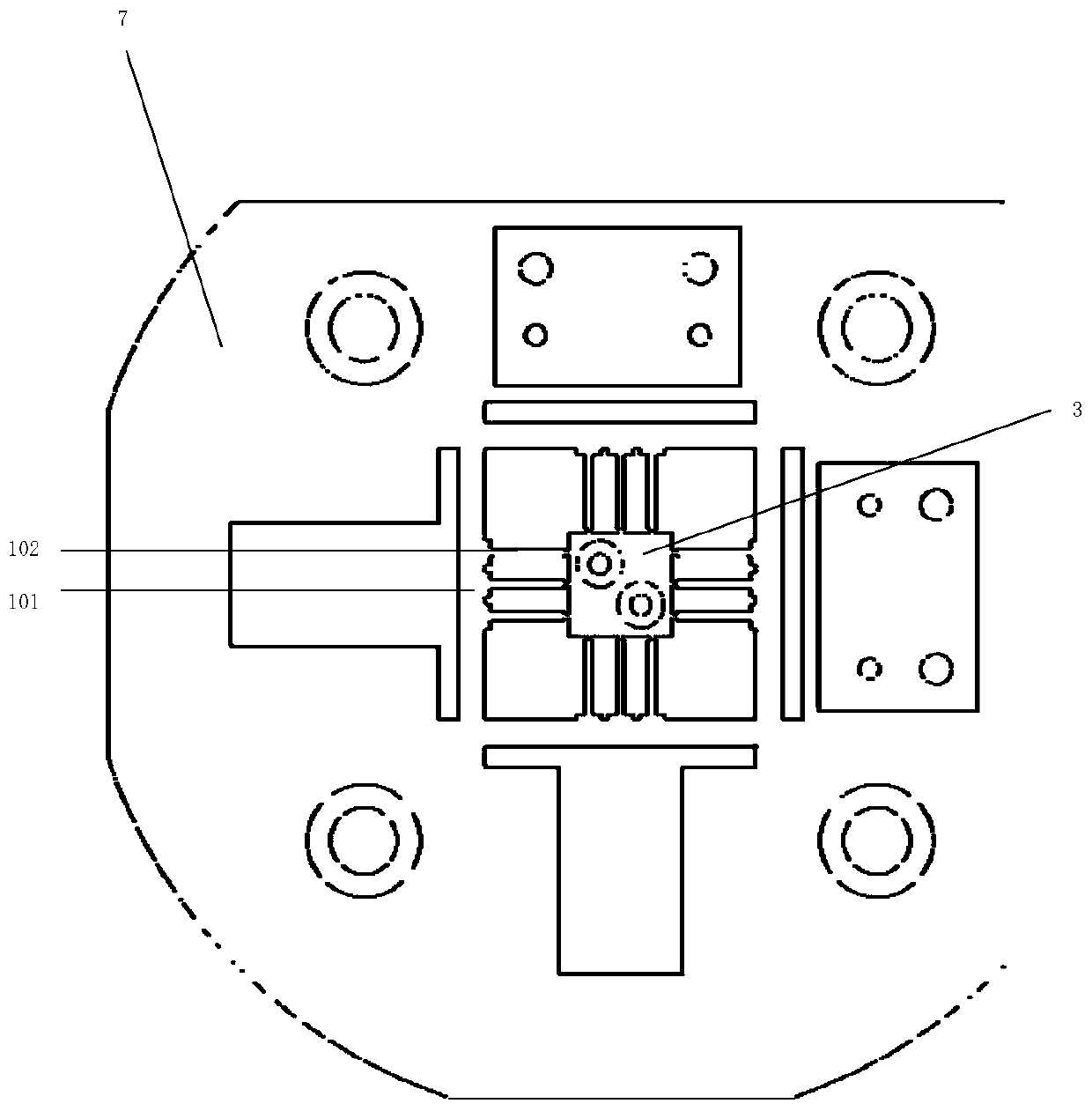

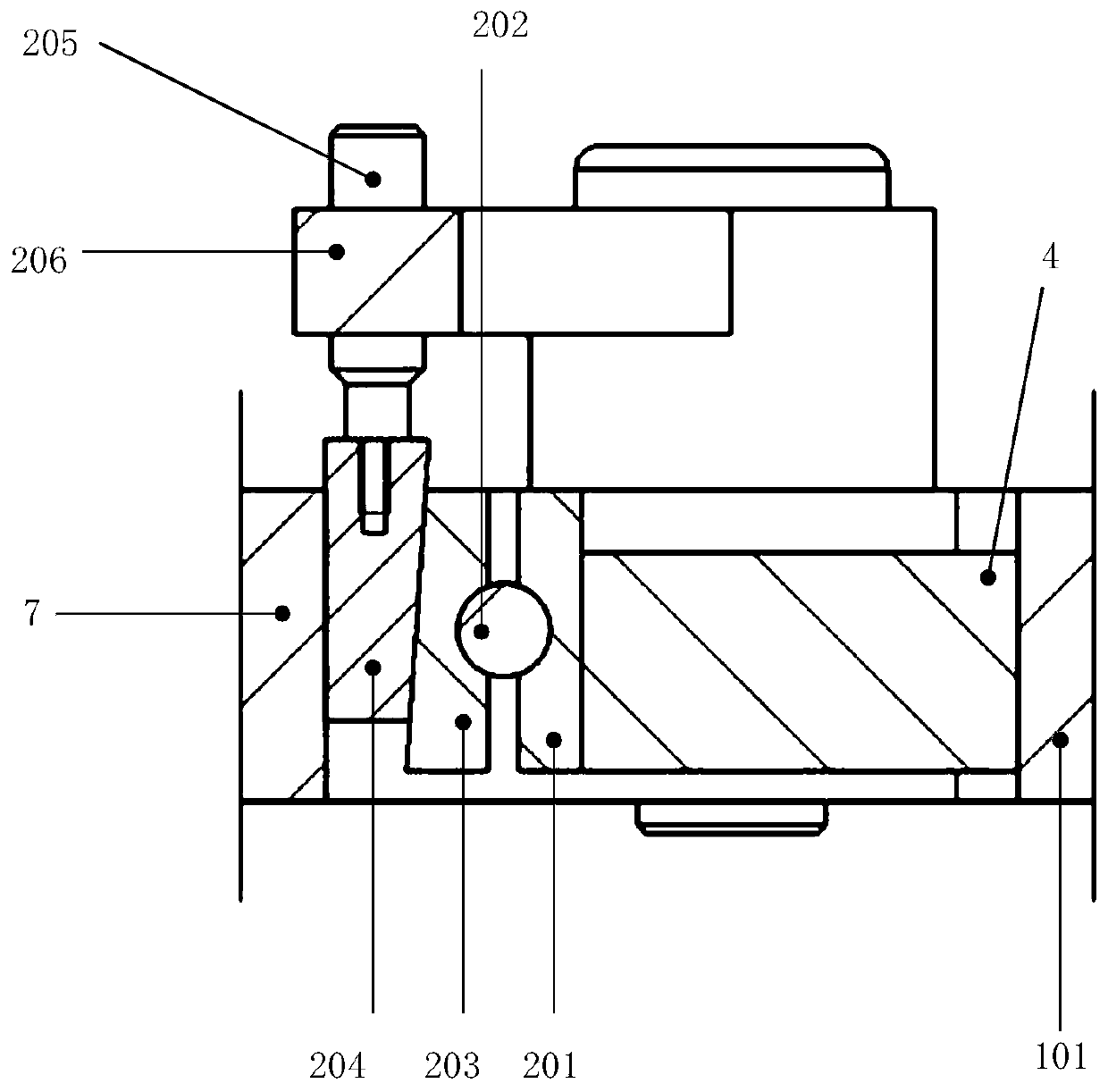

[0033] Such as figure 1 , 2 , 3, a high-bandwidth two-degree-of-freedom parallel flexible precision positioning platform, including:

[0034] The fixed frame 7 has a central hollow part in the middle, and an offset hollow part is respectively arranged along the X and Y centerline directions of the central hollow part;

[0035] Four groups of compliant units 1 are arranged on the inner wall of the central hollow part in a cross-shaped symmetrical connection with each other;

[0036] The end mobile platform 3 is located in the center of the central hollow part and the four sides are respectively connected with the flexible hinge ends of each compliant unit 1 pointing to the center of the central hollow part, and is used as a displacement output of the compliant positioning platform to provide loading conditions for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com