Spark plug electrode, spark plug and method for manufacturing spark plug electrode

A technology of spark plugs and electrodes, applied in spark plug manufacturing, spark plugs, circuits, etc., can solve problems such as material loss, and achieve the effects of improving corrosion resistance and erosion resistance, improving connectivity, and high corrosion and erosion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be described in detail with the aid of embodiments. Only the main aspects of the invention are shown in the drawings. All other aspects have been left out for clarity. Furthermore, the same reference numerals denote the same components.

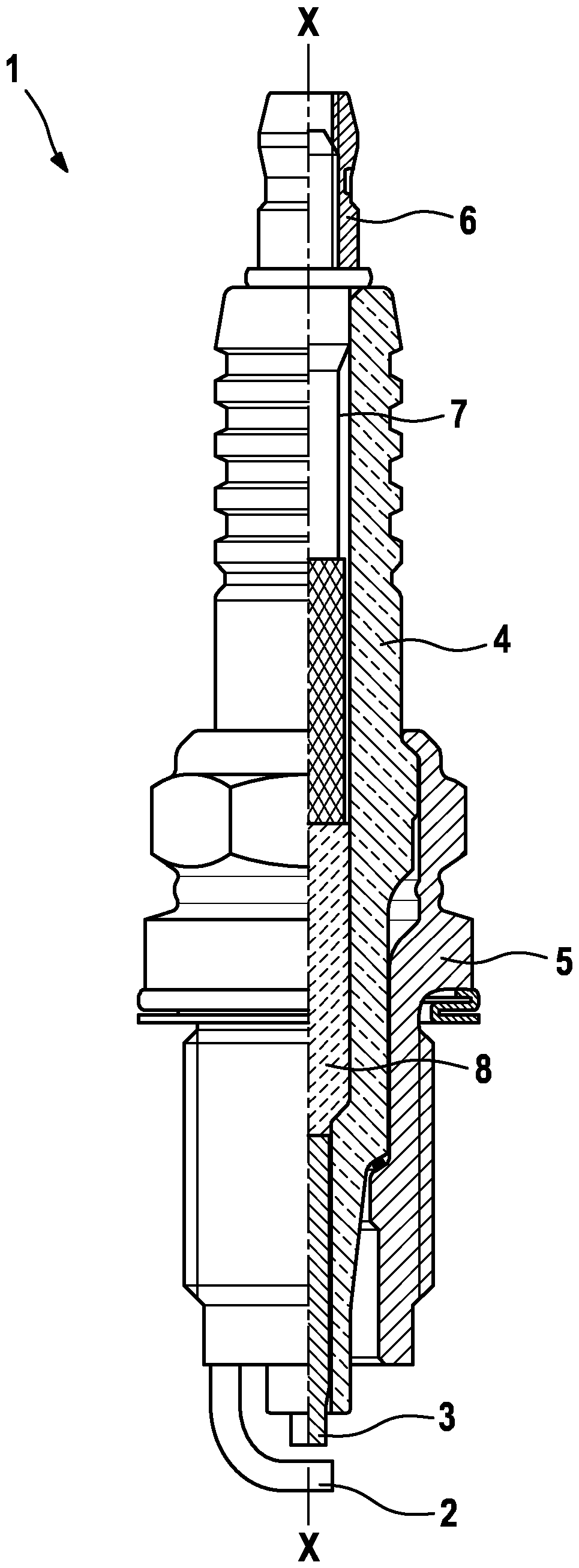

[0024] as by figure 1 It can be seen that the spark plug 1 according to one embodiment comprises a ground electrode 2 and a center electrode 3 . The insulator 4 is arranged such that the intermediate electrode 3 protrudes slightly from the insulator 4 in a known manner. The insulator 4 itself is partially surrounded by a housing 5 . Reference numeral 6 denotes an electrical connection nut. An electrically conductive connection is provided by an electrical connection nut 6 via a connection screw 7 and a connection element 8 made of conductive glass to the intermediate electrode 3 is provided.

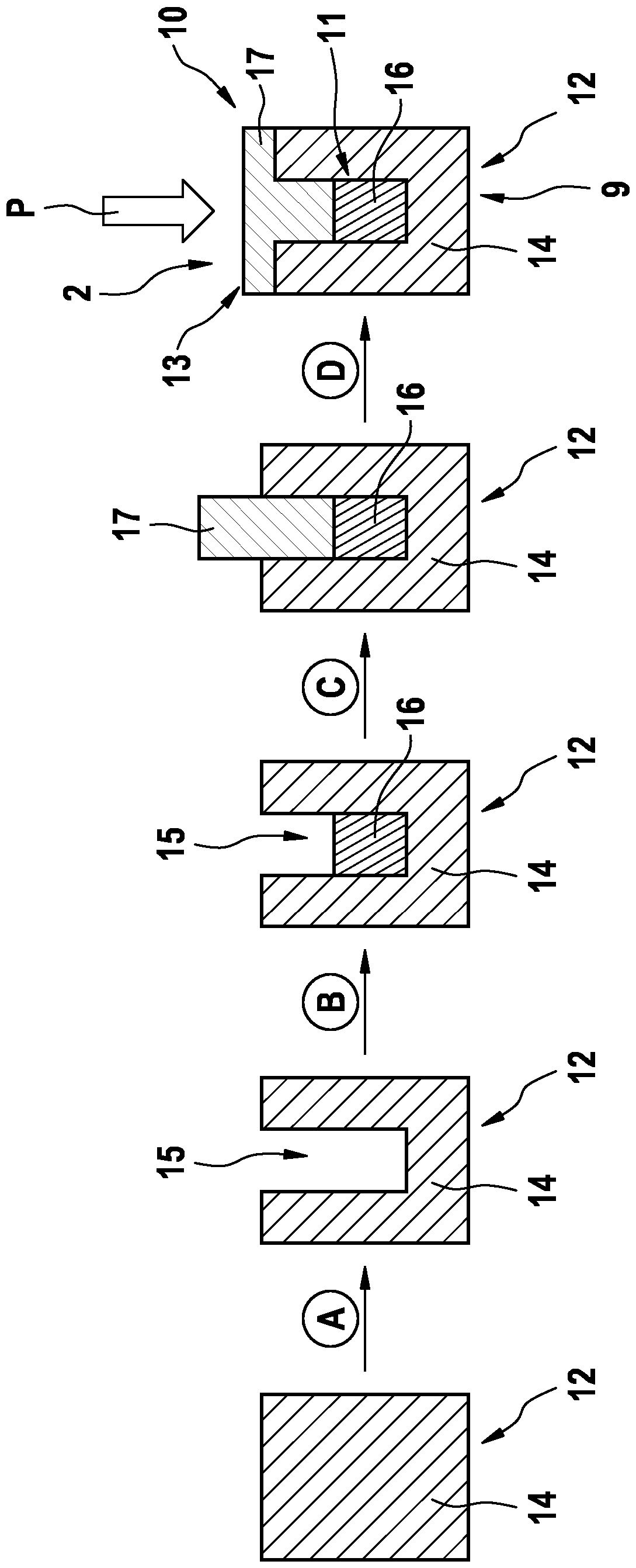

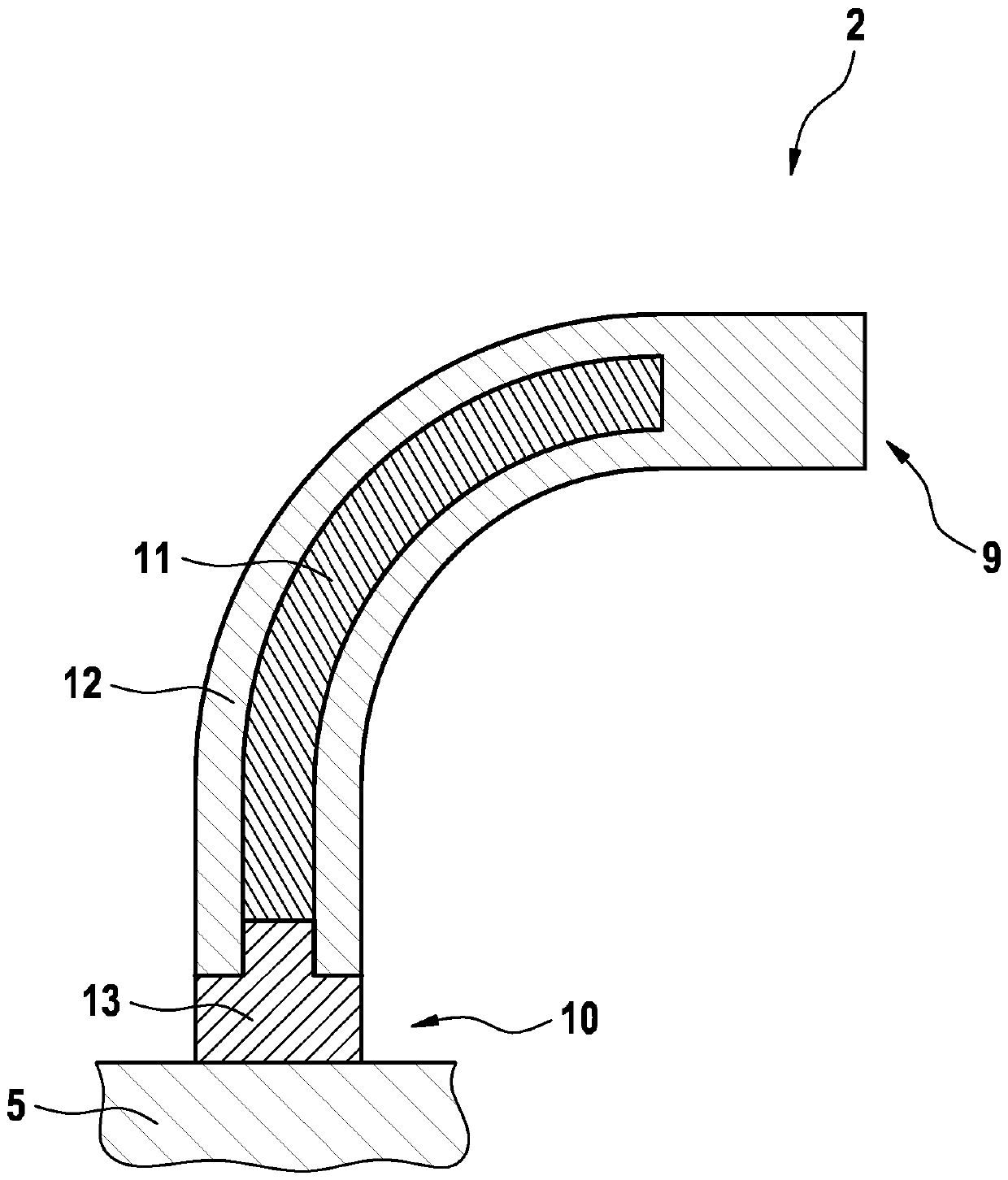

[0025] According to the invention, at least one of the electrodes is now specially designed. to this end, figure 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com