Special blend oil special for crisp frying and applications thereof

A technology for reconciling oil and oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

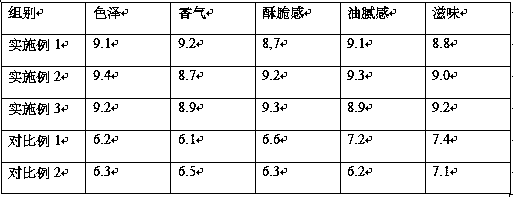

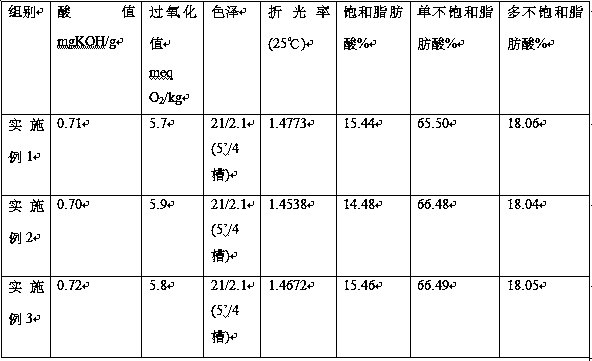

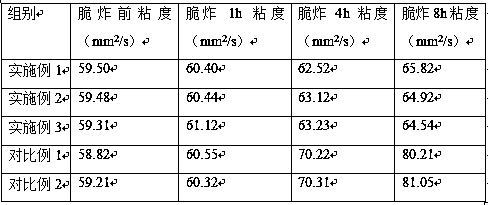

Examples

Embodiment 1

[0029] A special blending oil for crispy frying. In terms of weight percentage, the special blending oil for crispy frying includes: 40% rice oil, and 60% high oleic sunflower oil.

[0030] The application of the special blending oil for crispy frying on crispy fried potatoes comprises the following steps: S11. cutting the potatoes into potato sticks with a width of 0.5-1 cm and a length of 4-5 cm; S12. washing the potato sticks in step S11, The retained moisture is 30-40%; S13. Heat the blended oil to 170-180°C, and fry the potato sticks in step S12 in the blended oil for 3 minutes; S14. Cool the fried potato sticks in step S13 to room temperature; S15 .Fry the cooled potato strips in oil for 30~35s.

Embodiment 2

[0032] A special blending oil for crispy frying. In terms of percentage by weight, the special blending oil for crispy frying includes: 45% rice oil and 55% high oleic sunflower oil.

[0033] The application of the special blending oil for crispy frying on crispy fried potatoes comprises the following steps: S11. cutting the potatoes into potato sticks with a width of 0.5-1 cm and a length of 4-5 cm; S12. washing the potato sticks in step S11, The retained moisture is 30-40%; S13. Heat the blended oil to 170-180°C, and fry the potato sticks in step S12 in the blended oil for 3 minutes; S14. Cool the fried potato sticks in step S13 to room temperature; S15 .Fry the cooled potato strips in oil for 30~35s.

Embodiment 3

[0035] A special blending oil for crispy frying. In terms of weight percentage, the special blending oil for crispy frying includes: 35% of rice oil and 65% of high oleic sunflower oil.

[0036] The application of the special blending oil for crispy frying on crispy fried potatoes comprises the following steps: S11. cutting the potatoes into potato sticks with a width of 0.5-1 cm and a length of 4-5 cm; S12. washing the potato sticks in step S11, The retained moisture is 30-40%; S13. Heat the blended oil to 170-180°C, and fry the potato sticks in step S12 in the blended oil for 3 minutes; S14. Cool the fried potato sticks in step S13 to room temperature; S15 .Fry the cooled potato strips in oil for 30~35s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com