Preparation method of gradient elastic waist for paper diapers with one-way moisture transfer function

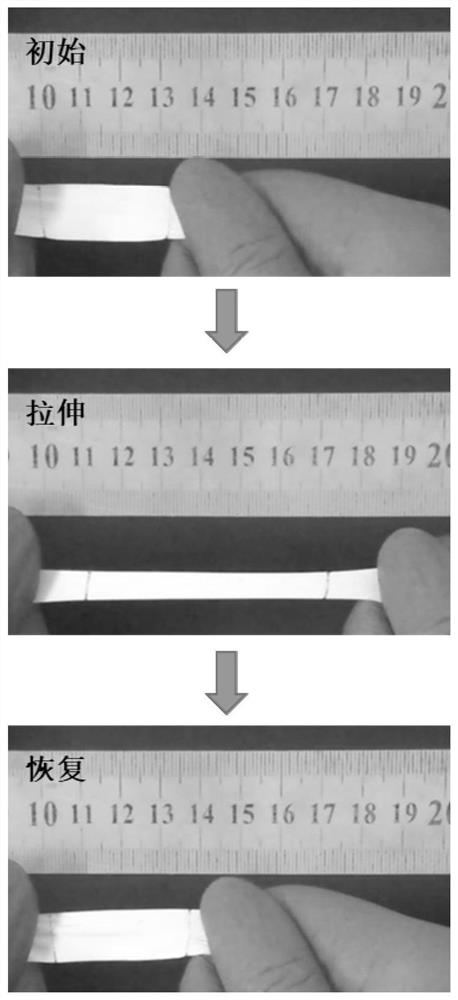

A one-way moisture-guiding and elastic waistline technology, applied in the field of baby hygiene products, can solve the problems of easy sultry sweating, poor air permeability, etc., and achieve the effect of simple process and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a diaper with a unidirectional wet-guiding function of a gradient elastic waistline, the specific steps are:

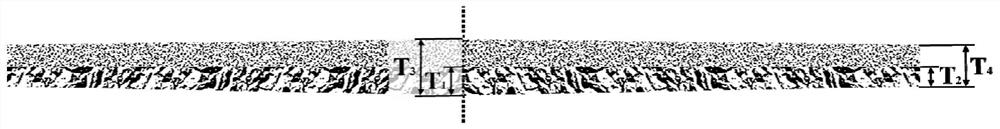

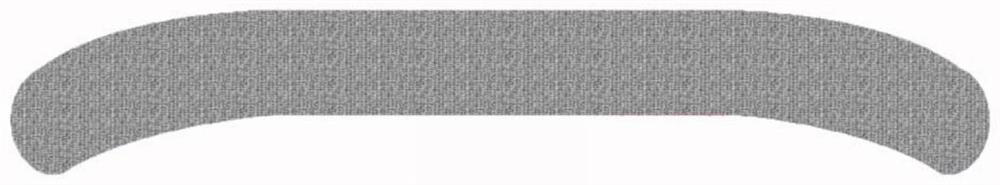

[0039] The first step: add the hydrophobic agent amino silicone oil to the solvent N,N-dimethylformamide, stir evenly, and then add the polyurethane to obtain a hydrophobic polyurethane spinning with a mass fraction of amino silicone oil of 2% and a mass fraction of polyurethane of 10%. Silk dope; the hydrophobic polyurethane spinning dope was spun by an electrospinning device to prepare a hydrophobic fiber membrane with an average pore size of 3.0 μm. The spinning temperature was 26.5°C, the relative humidity was 65%, and the voltage was 40kV. The distance is 20cm, the perfusion speed of the spinning solution is 3ml / h, the obtained fiber diameter is 800nm, and the distance of the sliding table is adjusted step by step from large to small in the spinning process (40cm, 35cm, 30cm, 25cm, 20cm, 15cm, 10cm, 5cm, 0cm) to prepare a fibrous me...

Embodiment 2

[0044] A preparation method of a diaper with a unidirectional wet-guiding function of a gradient elastic waistline, the specific steps are:

[0045] The first step: add the hydrophobic agent cetyltrimethoxysilane to the solvent N,N-dimethylformamide, stir evenly, and then add the polyurethane to obtain a mass fraction of cetyltrimethoxysilane of 3% , a hydrophobic polyurethane spinning dope with a polyurethane mass fraction of 10%; the hydrophobic polyurethane spinning dope was spun by an electrospinning device to prepare a hydrophobic fiber membrane with an average pore size of 2.2 μm, and the spinning temperature was 26.5 ℃ , the relative humidity is 80%, the voltage is 50kV, the receiving distance is 20cm, the perfusion speed of the spinning solution is 3ml / h, the obtained fiber diameter is 700nm, and the distance of the slide table is adjusted step by step from large to small during the spinning process (40cm, 35cm, 30cm, 25cm, 20cm, 15cm, 10cm, 5cm, 0cm) to prepare a fibr...

Embodiment 3

[0050] A preparation method of a diaper with a unidirectional wet-guiding function of a gradient elastic waistline, the specific steps are:

[0051] The first step: add the hydrophobic agent polydimethylsiloxane into the solvent N,N-dimethylformamide, stir evenly, and then add the polyurethane to obtain a polydimethylsiloxane with a mass fraction of 3% and a polyurethane The hydrophobic polyurethane spinning stock solution with a mass fraction of 15%; the hydrophobic polyurethane spinning stock solution was spun by an electrospinning device to prepare a hydrophobic fiber membrane with an average pore size of 2.5 μm, and the spinning temperature was 26.5 °C, relative to The humidity is 85%, the voltage is 50kV, the receiving distance is 20cm, the perfusion speed of the spinning solution is 3ml / h, the diameter of the obtained fiber is 850nm, and the distance of the sliding table is adjusted step by step from large to small during the spinning process (30cm, 25cm, 20cm, 15cm, 10c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com