Intelligent dry separator of stainless steel machine body

A dry sorter, stainless steel technology, applied in the parts of the instrument, shielding, reactors, etc., can solve the problems of high mechanical strength, easy rust of steel structure materials, and shortened service life of sorting equipment, so as to avoid clogging, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

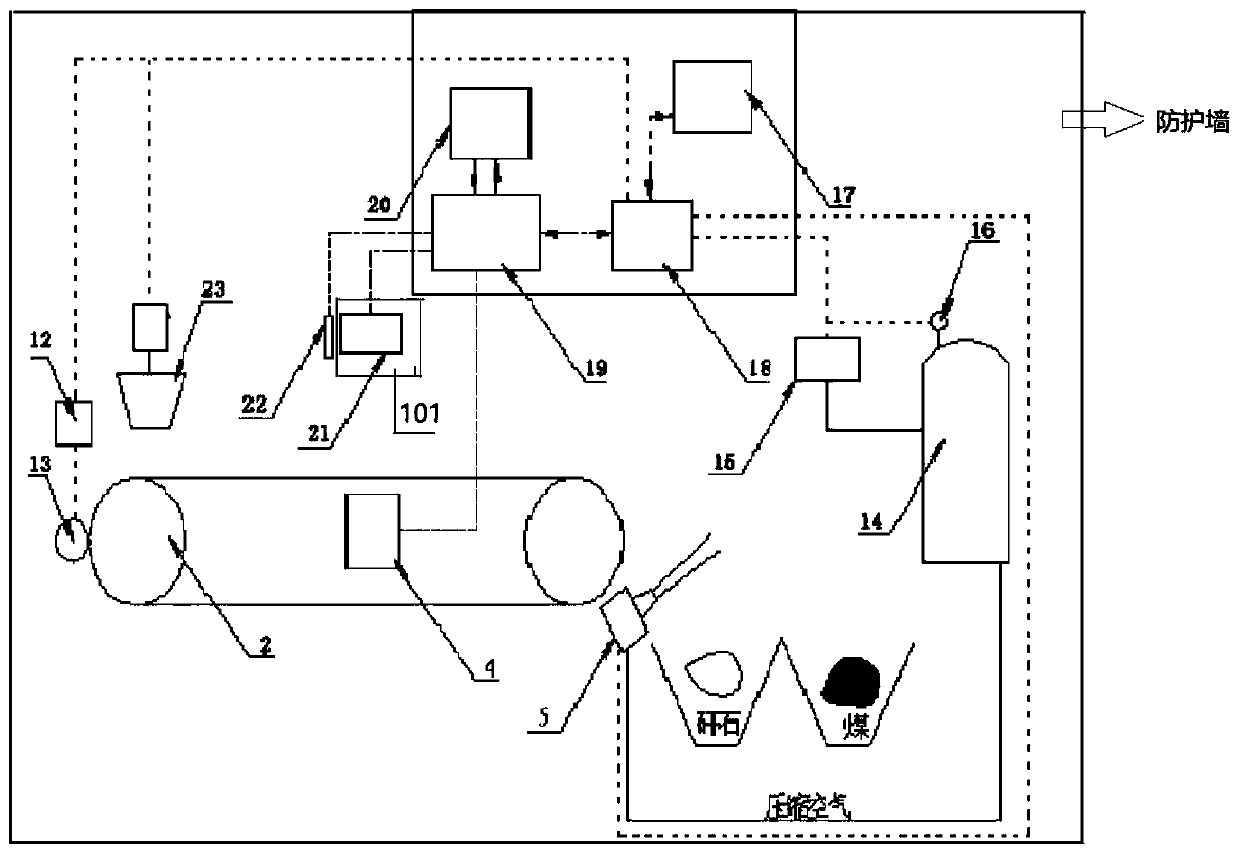

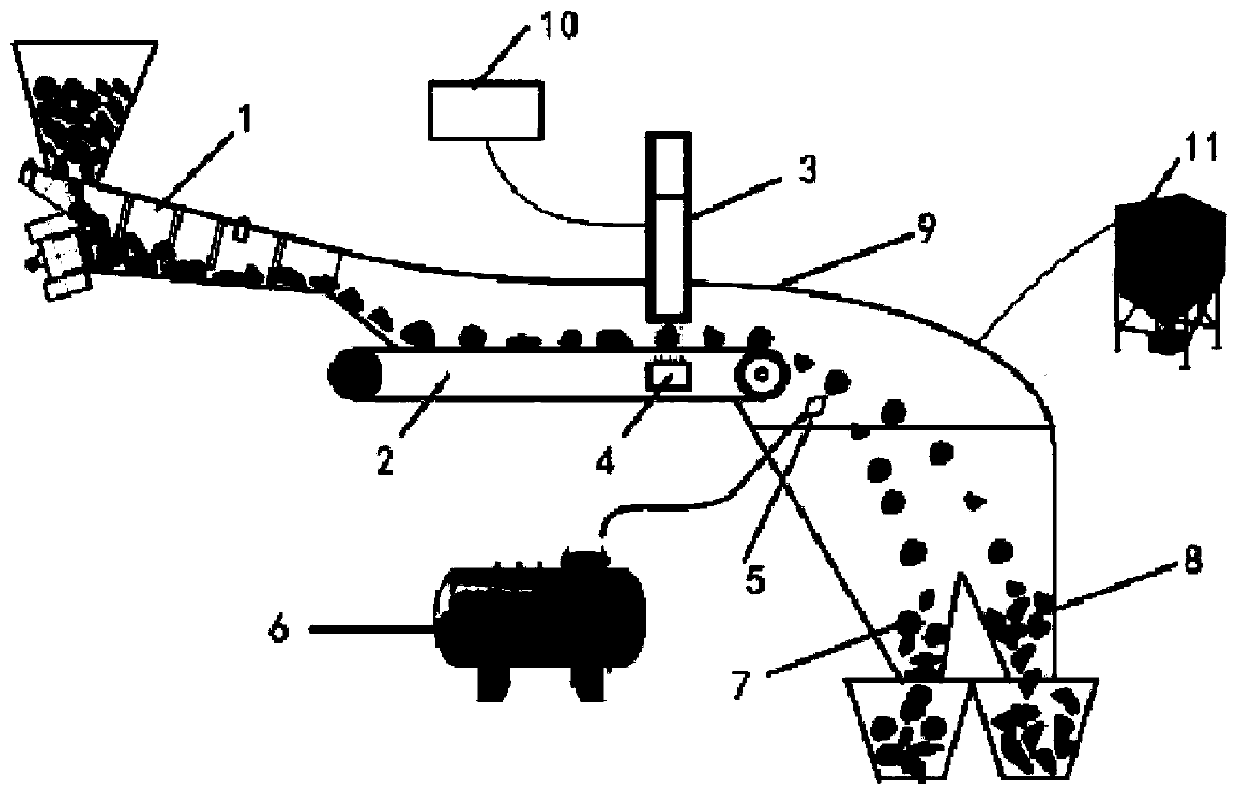

[0020] refer to Figure 1 to Figure 2 An embodiment of an intelligent dry separation machine with a stainless steel body of the present invention will be further described.

[0021] An intelligent dry separator with a stainless steel body, the whole body of which is made of stainless steel, the X-ray source 21 is placed in the protective shell 101, and the protective shell is preferably a radiation-proof lead bag. Further, a protective wall is provided around the intelligent dry separator for secondary shielding of the X-ray source.

[0022] The protective walls are made of lead plates and concrete walls, or barium cement walls with cement added with barium sulphate or barite powder. The thickness of the protective wall or shielding material is estimated using half-value layers or half-value layers. Preferably, the concrete wall is made of a material obtained by sintering a compound of S.Pb.Fe.

[0023] Furthermore, the protective wall is made of lead rubber or radiation-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com