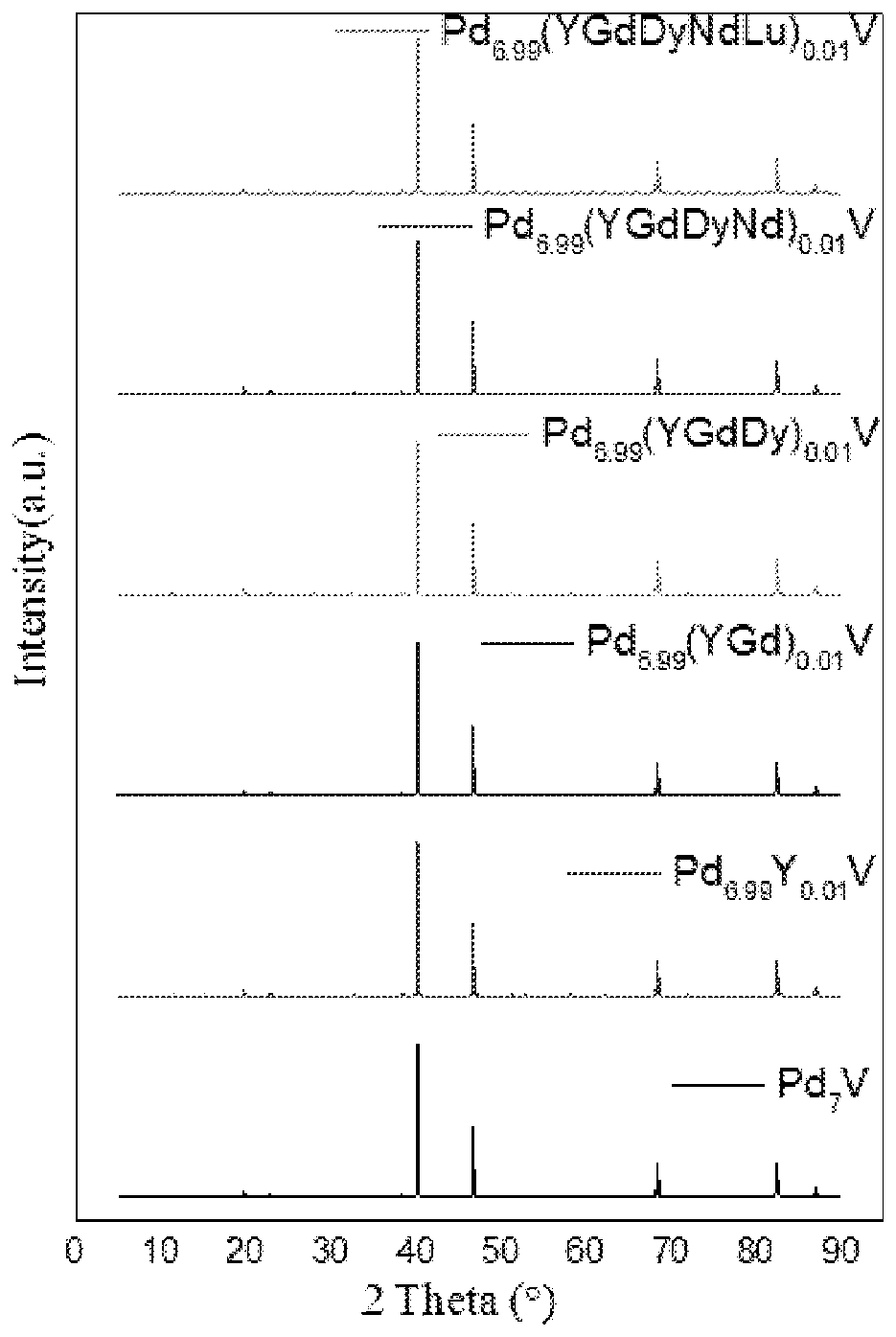

Rare earth enhanced palladium alloy and preparation method thereof

A palladium alloy and rare earth technology, applied in the field of rare earth reinforced palladium alloy and its preparation, can solve the problems of easy oxidation and creep, and achieve the effect of improving toughness and hardness, high specific strength, hardness and high temperature creep performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

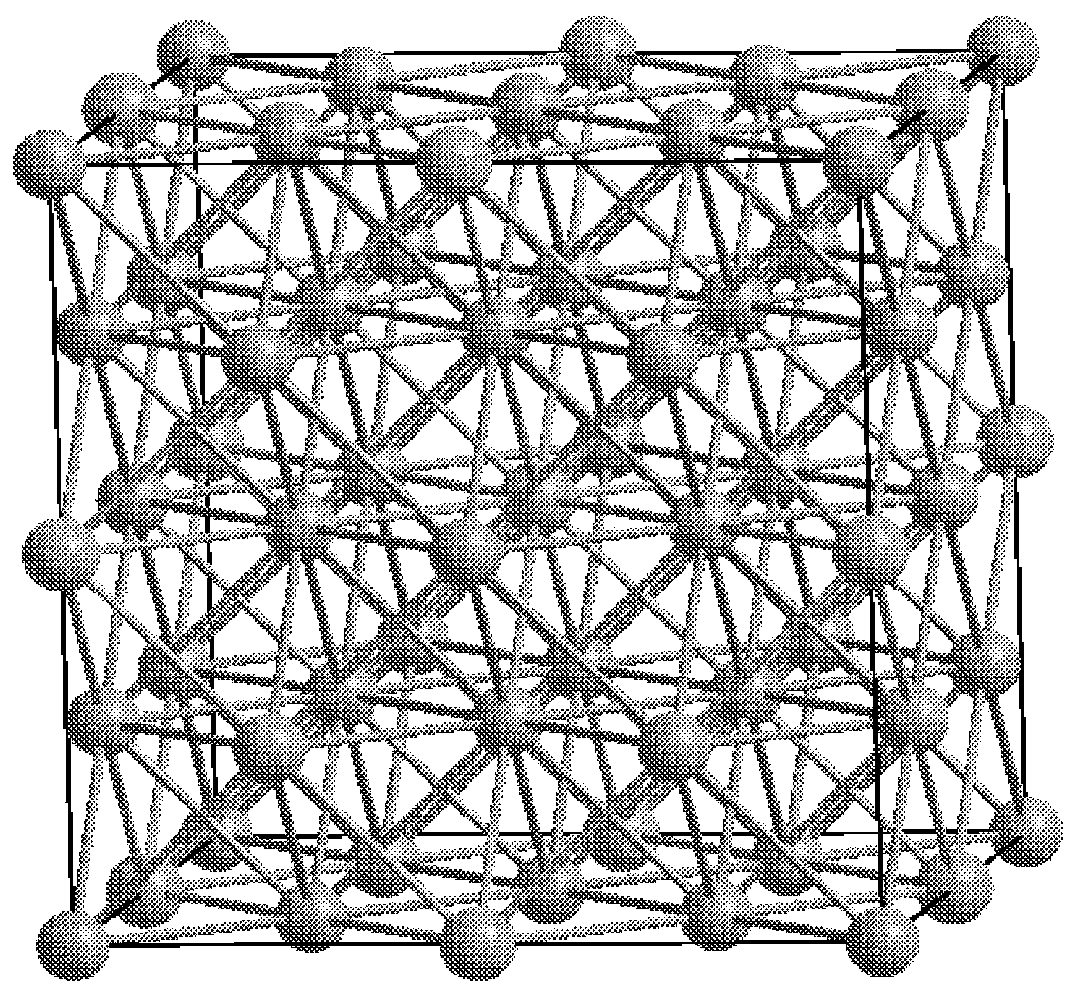

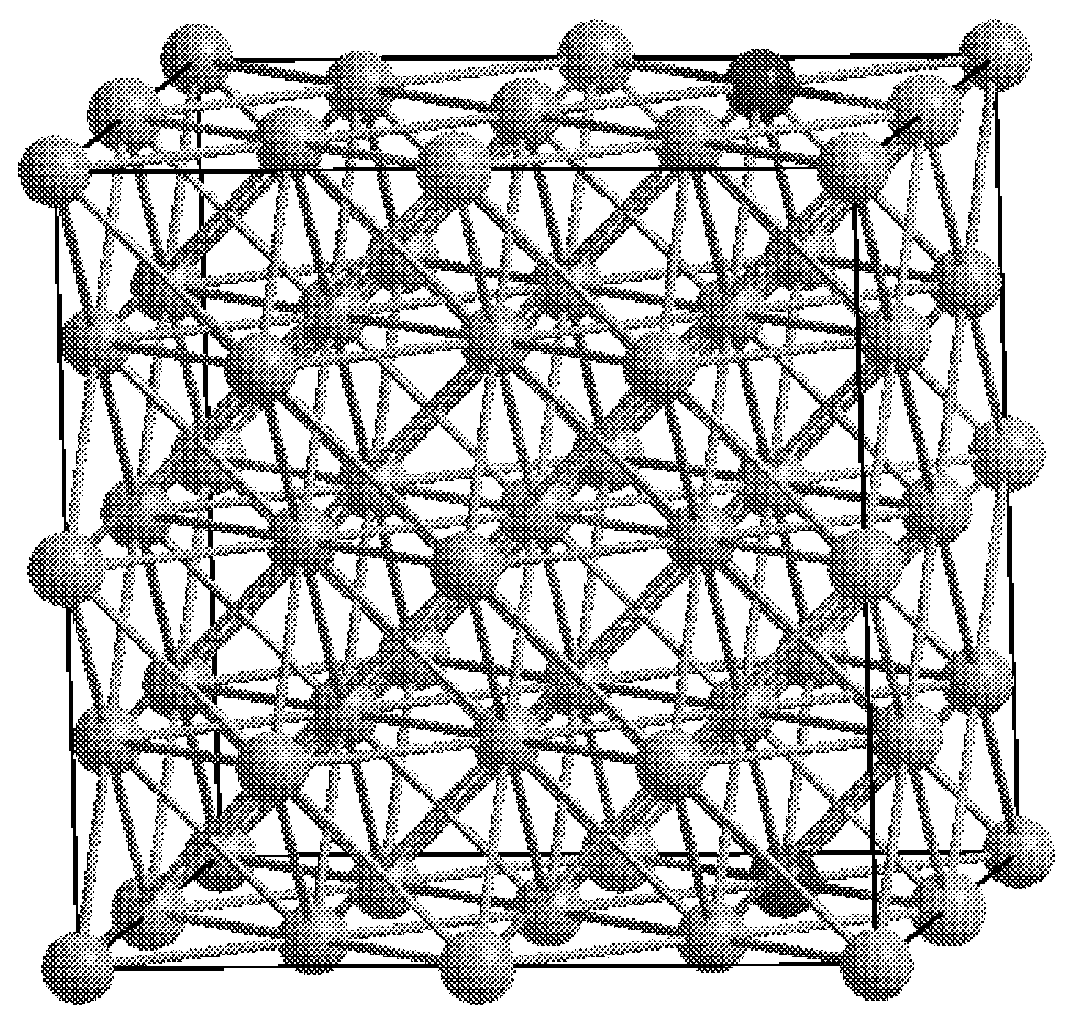

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned rare earth reinforced palladium alloy comprises the following steps:

[0039] Step (1): Palladium, vanadium and rare earth are subjected to surface derusting or degreasing treatment, and the molar ratio of Pd:RE:V is (7-x):x:1 palladium, rare earth and vanadium raw materials, wherein palladium The purity of , vanadium and rare earth RE is not less than 99.95wt%.

[0040] Step (2): Before putting in the raw materials, the vacuum furnace is repeatedly flushed with high-pressure pure argon for 3 times to remove the remaining impurity elements in the vacuum furnace and ensure that the vacuum degree in the vacuum furnace before smelting is less than 1.0E -4 Pa; put the raw materials prepared in step (1) into the crucible of the vacuum furnace (model KZG2-25), then pump the pressure in the vacuum furnace to below 18-20Pa, turn on the power, and feed the vacuum furnace with a power of 15-30KW Heat slowly, increase the power to 45-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com