Multilayer assembled electric furnace hearth

An assembled electric furnace technology, applied in the furnace, furnace, furnace bottom, etc., can solve the problems of high radial heat radiation and heat conduction of the electric furnace, increase the use and maintenance cost of the electric furnace, reduce the service life of the furnace, etc., to improve the production environment, The effect of shortening the production cycle and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

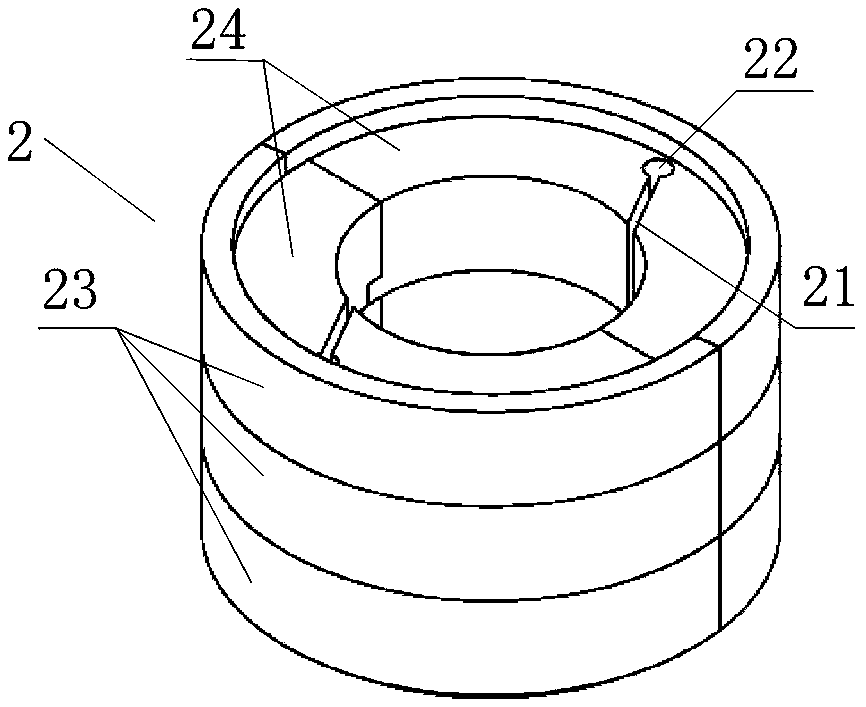

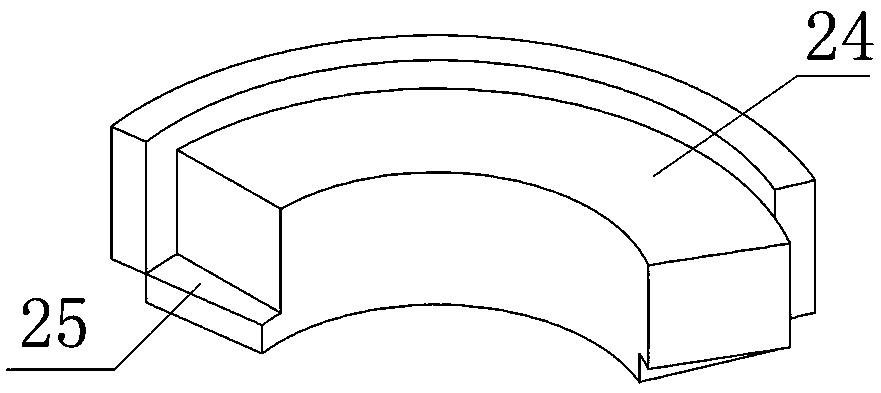

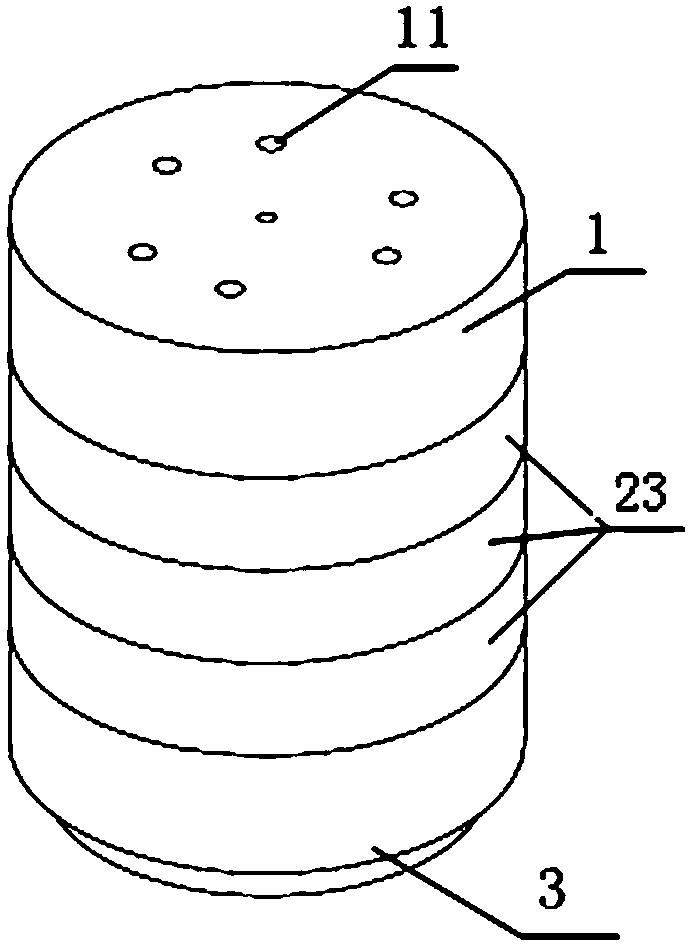

[0026] Such as image 3 , Figure 4 Shown is the multi-layer assembled type electric furnace hearth of the present invention, it comprises, ring-shaped furnace wall 2, and furnace roof 1 and furnace bottom 3 respectively positioned at the upper and lower sides of described furnace wall 2, the present invention is according to bell jar type, lifting According to the actual situation of electric furnace and pit type experimental electric furnace, the positions of furnace top 1 and furnace bottom 3 can be interchanged, image 3 It is suitable for the hearth of a bell-type or lift-type experimental electric furnace, the furnace roof 1 is located on the upper side, and the furnace bottom 3 is located on the lower side, Figure 4 To be suitable for the hearth of a well-type experimental electric furnace, the furnace roof 1 is located on the lower side, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com