Sine type optical pressure dynamic calibration cabin considering temperature control and optical path layout

A temperature-controlled, dynamic calibration technique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

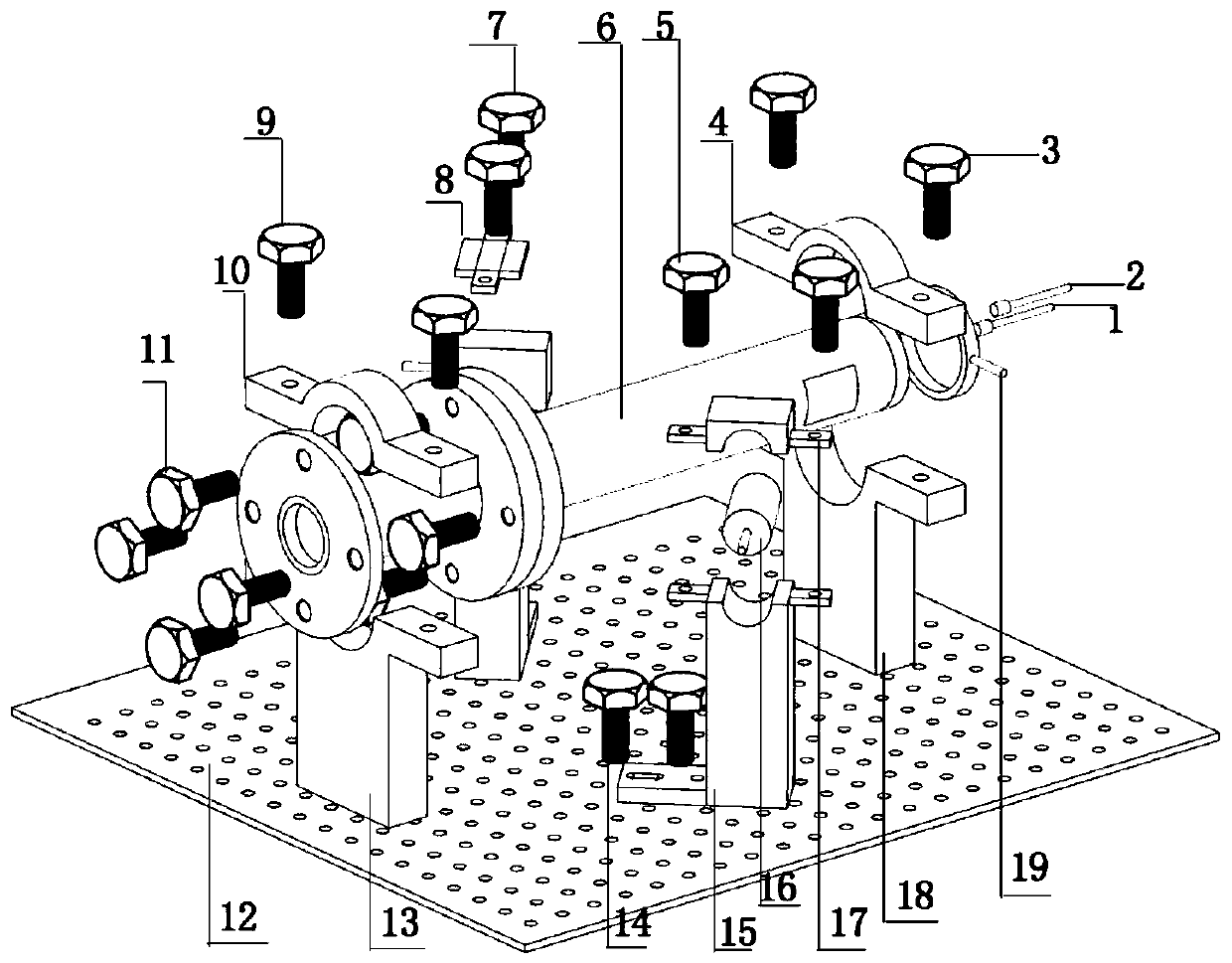

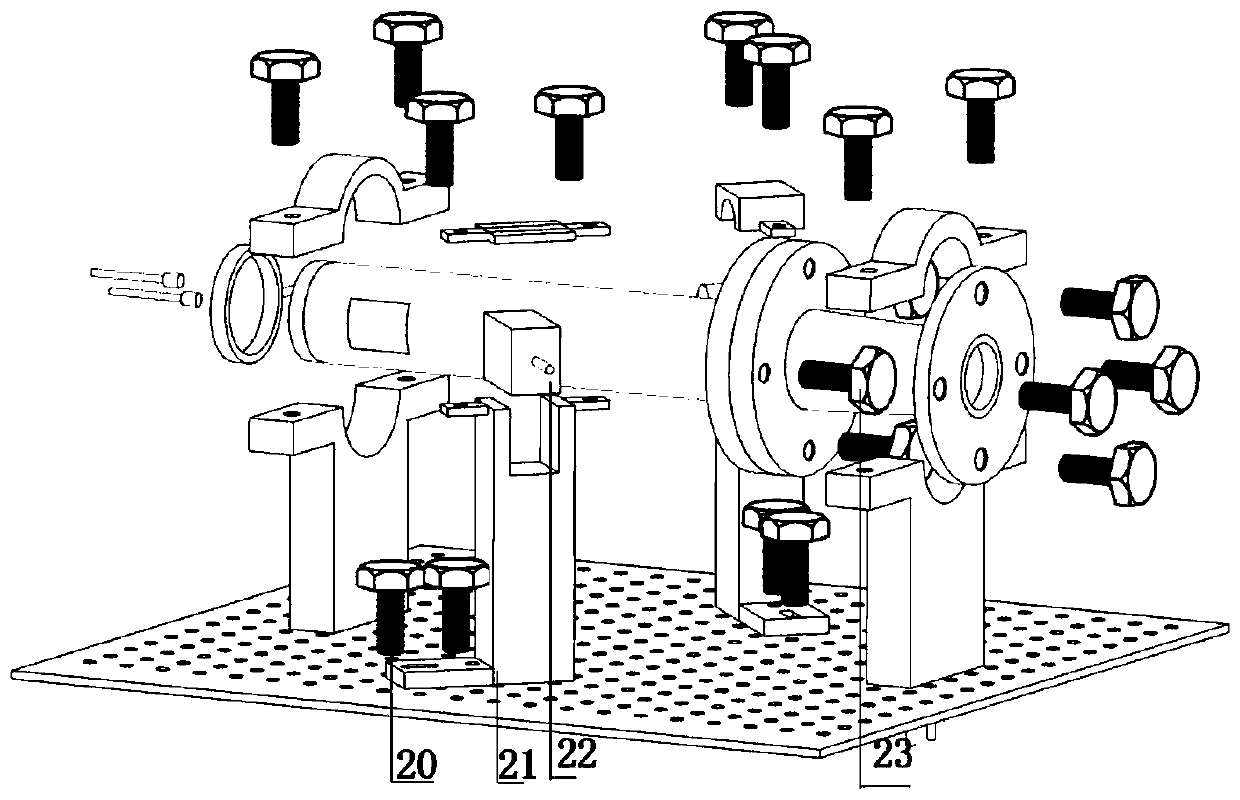

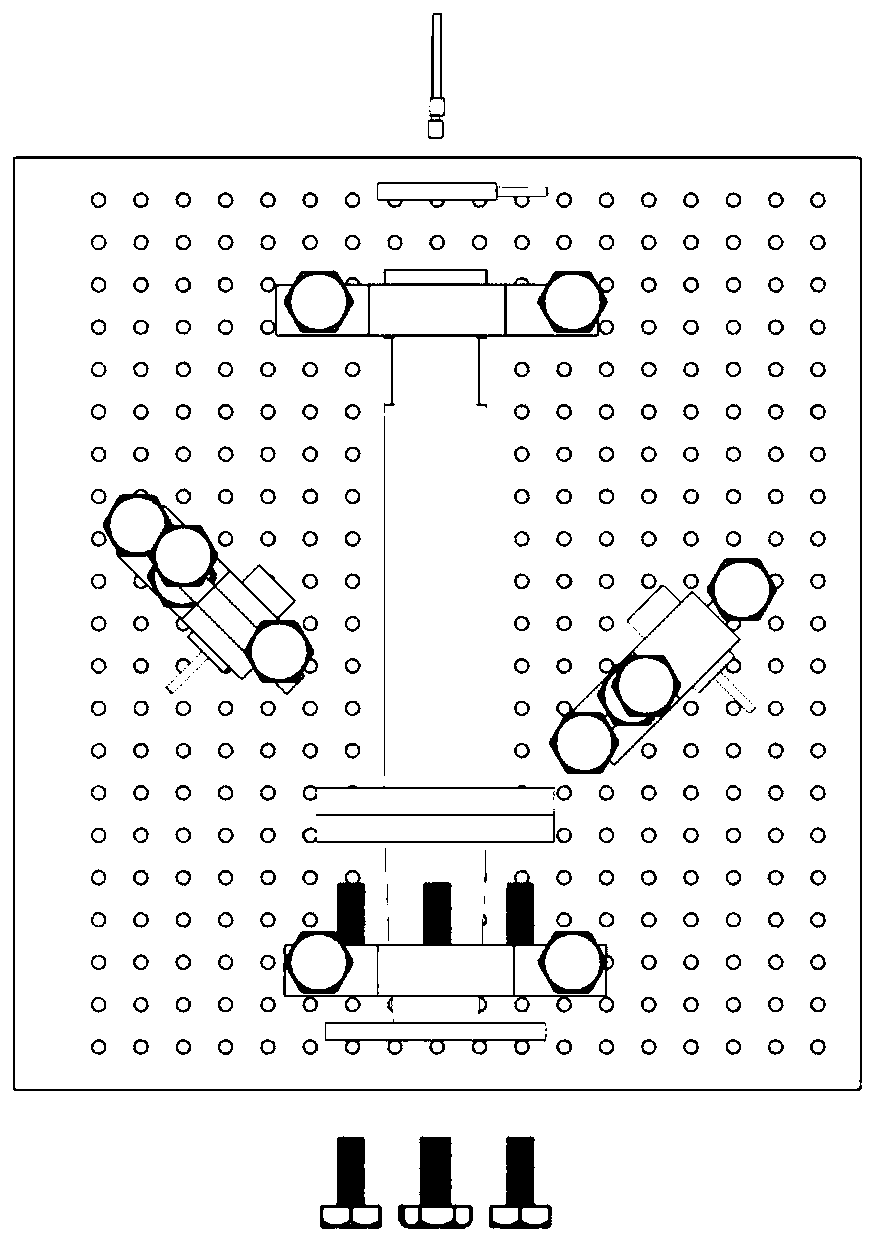

[0036] The present invention will now be further described in conjunction with the embodiments and drawings:

[0037] 1. Selection and connection method of connecting components with standing wave tube

[0038] Such as figure 1 Said standing wave tube 6 is a standing wave tube designed in the first edition of the dynamic pressure calibration chamber for sinusoidal optical pressure sensitive paint. The dynamic pressure sensor 1 and the PT100 pressure nose temperature sensor 2 are connected to the standing wave tube 6 through a sensor protective sleeve. The PT100 pressure-nose temperature sensor can be attached to the surface of the optical pressure-sensitive coating for temperature measurement with high temperature measurement accuracy. The sensor selection accuracy is 1 / 3B accuracy, the measurable temperature accuracy is 0.1℃, and the measurable temperature range is -50℃ to 250℃, which meets the experimental requirements. The upper part 4 of the standing wave tube main section su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com