Laser ultrasound-based online air compressor cylinder surface crack detection method and system

A technology of laser ultrasound and surface cracks, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the difficulties of small crack detection, application limitations, and surface temperature effects. Larger problems, to achieve the effect of fast detection speed, small distance, and small spot diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0061] Example.

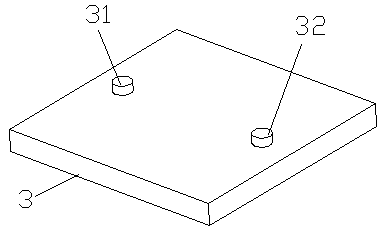

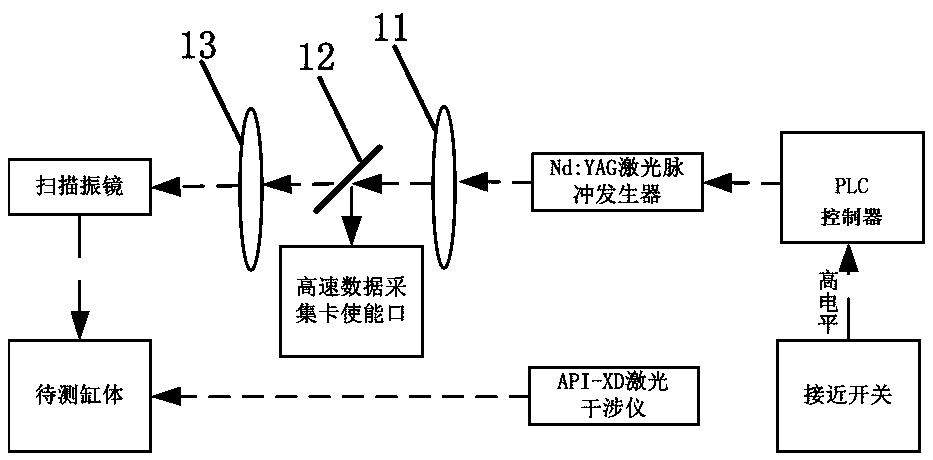

[0062] see Figure 1 to Figure 7 .

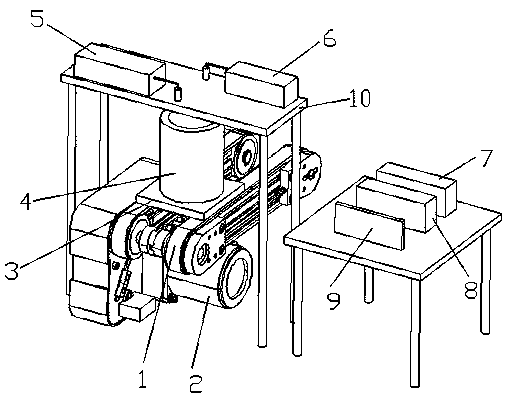

[0063] In this embodiment, the online detection system for cracks on the surface of the air compressor cylinder based on laser ultrasound includes a PLC controller, a cylinder conveyor 1, a transmission motor 2, a detection workbench 10, a laser interferometer 6, a high-speed data acquisition card 7, A data analysis system 8, a display screen 9 and a detection control box 5 integrated with a laser pulse generator and an optical path adjustment system.

[0064] The cylinder conveyor 1 and the transmission motor 2 are arranged under the detection workbench 10 , the cylinder conveyor 1 is driven by the transmission motor 2 , and the cylinder conveyor 1 is used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com