Giant dielectric thin film transistor

A technology of thin-film transistors and giant dielectrics, applied in transistors, circuits, electrical components, etc., can solve problems such as limited application range, slow ion speed, and poor temperature stability of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

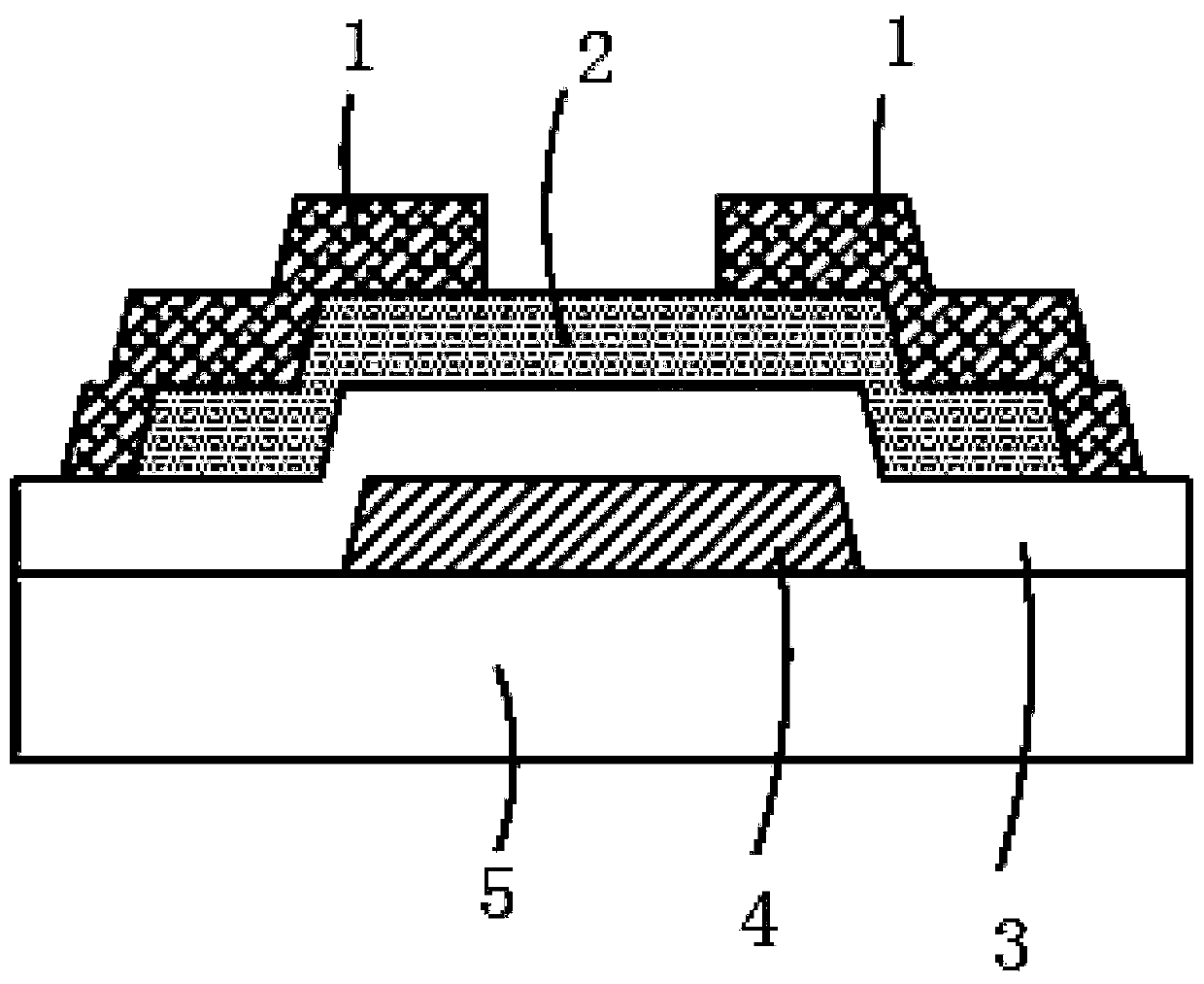

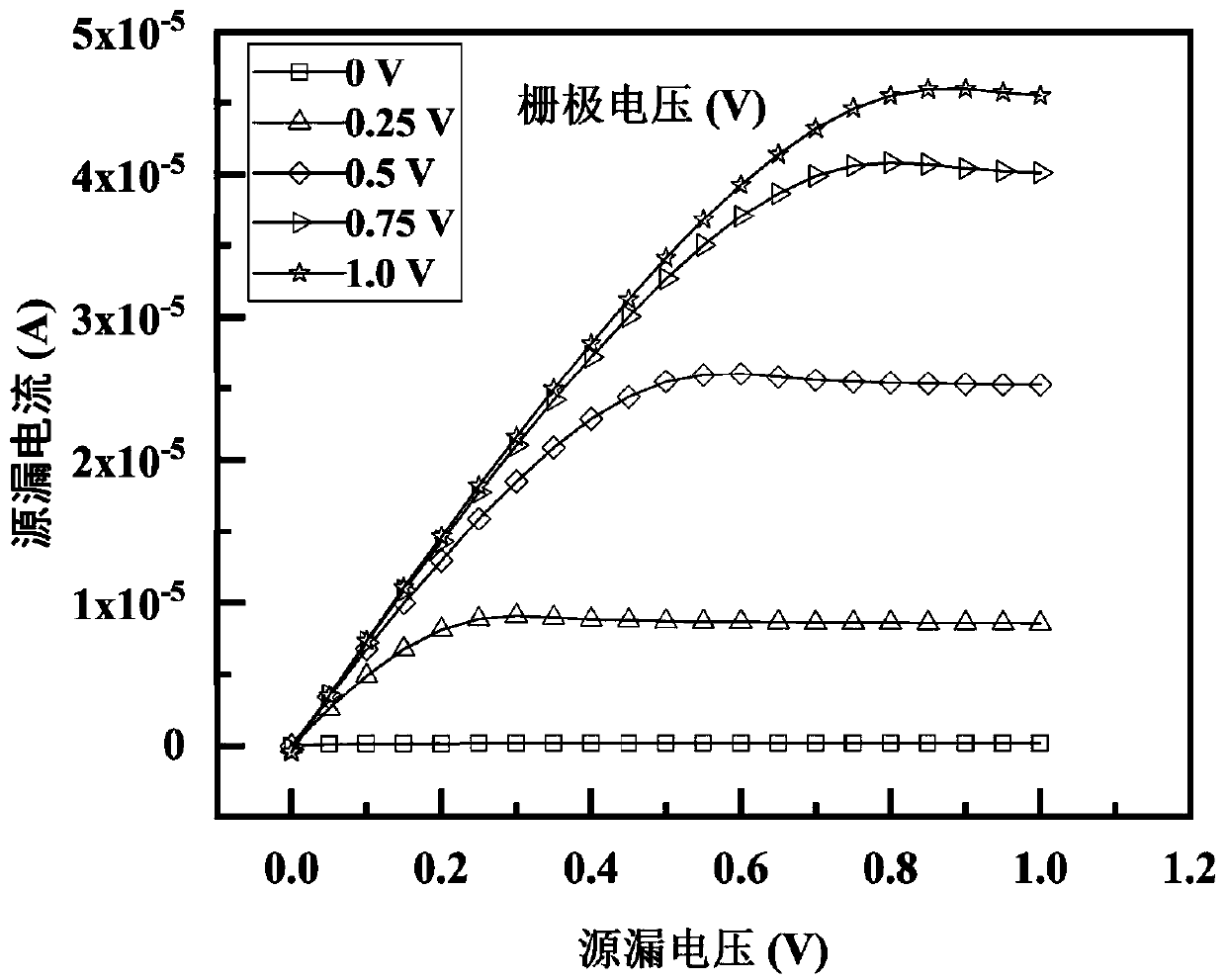

[0042] A giant dielectric thin film transistor is provided with a gate 4, a semiconductor 2 and a gate insulating layer 3 between the gate 4 and the semiconductor 2.

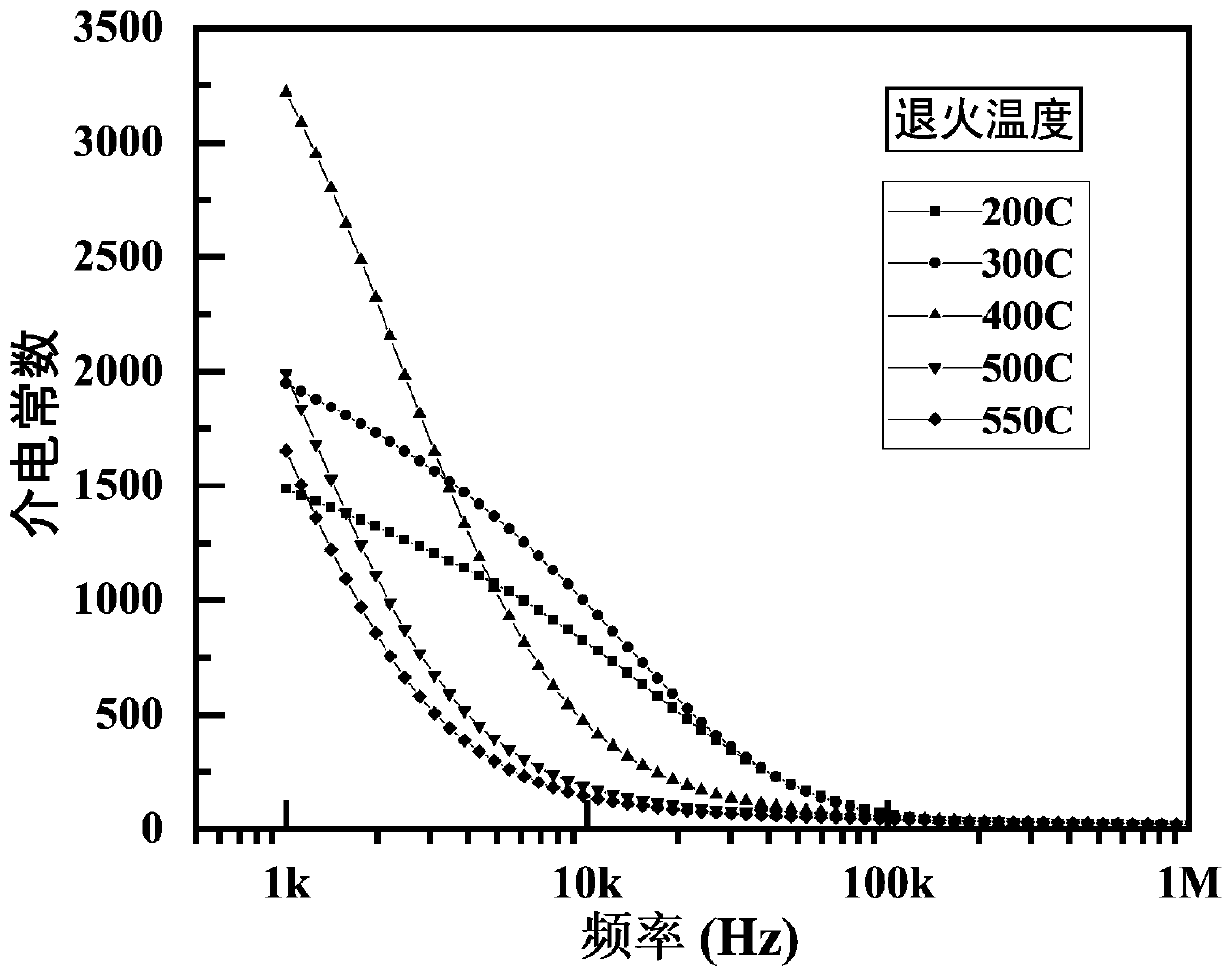

[0043] The gate insulating layer 3 is made of a giant dielectric material as the gate insulating layer 3 .

[0044] When the giant dielectric material is in the state of a ceramic block, the relative permittivity is greater than 10,000 at a frequency of 1 kHz, and when the giant dielectric material is in a thin film state, the relative permittivity is greater than 500 at 1 kHz.

[0045] Giant dielectric materials are non-ferroelectric ceramic materials.

[0046] The giant dielectric material of the present invention is CaCu 3 Ti 4 o 12 or CaCu 3 Ti 4 o 12 modified materials. The specific giant dielectric material of the present embodiment is CaCu 3 Ti 4 o 12 .

[0047] The gate insulating layer 3 is a giant dielectric material thin film prepared from a giant dielectric material at a temperature lower ...

Embodiment 2

[0056] A kind of giant dielectric thin film transistor, other characteristics are identical with embodiment 1, difference is: giant dielectric material of the present invention is A(Fe 1 / 2 G 1 / 2 )O 3 , wherein A is Ba, Sr, Ca or Pb, and G is Nb, Ta or Sb. The specific A(Fe 1 / 2 G 1 / 2 )O 3 , where A is Ba, G is Nb, that is, Ba(Fe 1 / 2 Nb 1 / 2 )O 3 .

[0057] The semiconductor 2 of the present invention is an oxide semiconductor 2, and the oxide semiconductor 2 contains Zn.

[0058] It should be noted that A in the present invention may be Ba, or Sr, Ca or Pb, and the specific implementation method depends on the actual situation. In the present invention, G can be Nb, Ta or Sb, and the specific implementation method depends on the actual situation.

[0059] It should be noted that the oxide semiconductor of the present invention may contain Zn, one of Sn, In, Cd or Ga, or a combination of various elements, and the specific implementation method depends on the actual situ...

Embodiment 3

[0062] A kind of giant dielectric thin film transistor, other characteristics are identical with embodiment 1, difference is: the giant dielectric material of the present invention is (M, N)-doped NiO, and wherein M is Li, Na or K, and N is Ti, Al, Si or Ta. Specifically, in this embodiment, M is Li and N is Ti, that is, (Li, Ti)-doped NiO.

[0063] It should be noted that M in the present invention can be Li, Na or K, and the specific implementation method depends on the actual situation. In the present invention, N can be Ti, or Al, Si or Ta, and the specific implementation method depends on the actual situation.

[0064] Compared with the gate insulating layer 3 of the TFT with the ion electric double layer, the giant dielectric thin film transistor of the present invention has the advantage of good frequency response, the frequency response of the inverter is greater than 500Hz, and low power consumption circuit, so it has great advantages in the display field Good appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com