a ceo 2 @mos 2 /g-c 3 n 4 Ternary composite photocatalyst and preparation method thereof

A ternary composite, photocatalyst technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve excellent visible light effect, achieve effective separation, and improve the effect of conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

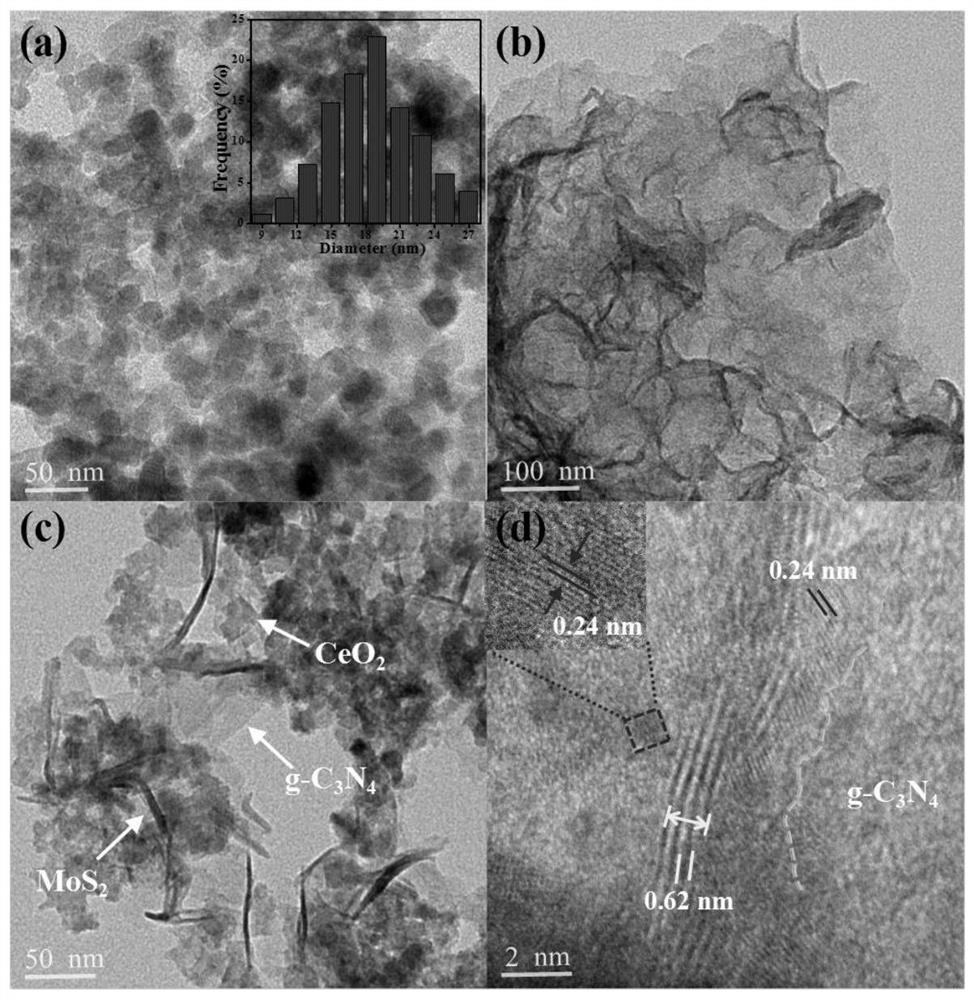

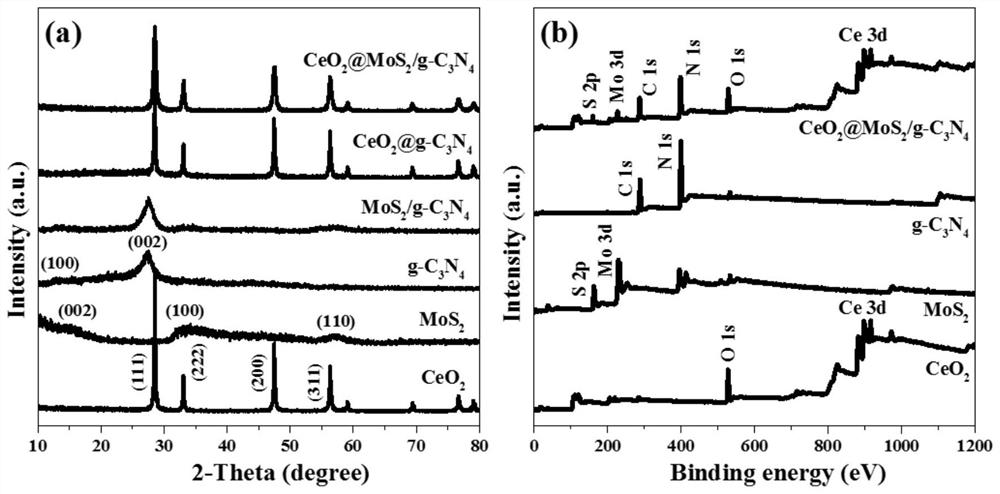

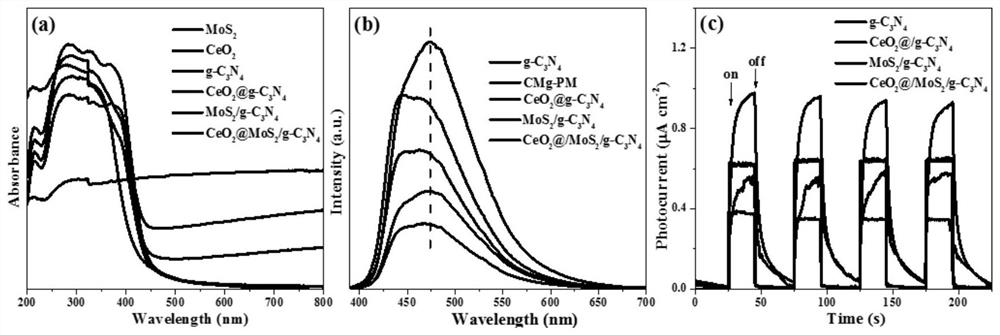

[0038] (1) Take 5g of urea in a muffle furnace, uniformly heat up to 550°C at a heating rate of 2°C / min, calcinate at a constant temperature for 6 hours, and after natural cooling, grind the obtained solid into fine powder to obtain g-C 3 N 4 Nanosheets. Such as figure 1 , 2 , 3, 4, 5, pure g-C 3 N 4 The morphology of the compound is a two-dimensional sheet structure without obvious stacking phenomenon, and the characteristic peaks attributed to C and N elements can be clearly observed in the X-ray diffraction pattern and X-ray photoelectron spectroscopy, which shows that this method is suitable for synthesis g-C 3 N 4 Nanosheets are of extremely high purity.

[0039] In (2), 0.2g of cerium oxide hexahydrate can be dissolved in a mixed solution of 0.05ml of butylamine, 10ml of toluene and 20ml of distilled water. After stirring evenly until completely dissolved, the resulting mixed solution is transferred to a hydrothermal reaction kettle, and the reaction kettle is sea...

Embodiment 2

[0044] (1) Take 5g of urea in a muffle furnace, uniformly heat up to 550°C at a heating rate of 2°C / min, calcinate at a constant temperature for 6 hours, and after natural cooling, grind the obtained solid into fine powder to obtain g-C 3 N 4 Nanosheets.

[0045] (2) Get 0.4g of cerium oxide hexahydrate and dissolve it in a mixed solution of 0.15ml of butylamine, 20ml of toluene and 30ml of distilled water, stir until completely dissolved, transfer the resulting mixed solution to a hydrothermal reaction kettle, and seal the reaction kettle, Placed in a 170°C oven for hydrothermal treatment for 24 hours. After the reaction, the obtained product was repeatedly washed with ethanol and deionized water, filtered and dried at 60°C, and then the dried reaction product was calcined at 170°C for 24 hours to obtain CeO 2 Nanocrystalline.

[0046] (3) Take 0.30g sodium molybdate dihydrate, 0.10g g-C 3 N 4 The nanosheets were ultrasonically dispersed in a mixed solution of 0.4ml L-cy...

Embodiment 3

[0051] (1) Take 5g of urea and place it in a muffle furnace, uniformly heat up to 600°C at a heating rate of 5°C / min, calcinate at a constant temperature for 4 hours, and after natural cooling, grind the obtained solid into fine powder to obtain g-C 3 N 4 Nanosheets.

[0052] (2) Get 0.6g of cerium oxide hexahydrate and dissolve it in a mixed solution of 0.25ml of butylamine, 30ml of toluene and 25ml of distilled water, stir until completely dissolved, transfer the resulting mixed solution to a hydrothermal reaction kettle, and seal the reaction kettle, Placed in a 180°C oven for hydrothermal treatment for 24 hours. After the reaction, the obtained product was repeatedly washed with ethanol and deionized water, filtered and dried at 60°C, and then the dried reaction product was calcined at 180°C for 24 hours to obtain CeO 2 Nanocrystalline.

[0053] (3) Take 0.40g sodium molybdate dihydrate, 0.15g g-C 3 N 4 The nanosheets were ultrasonically dispersed in a mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com