Manufacturing method of concrete artware with ceramic texture on surface

A production method and concrete technology, which are used in ceramic molding machines, decorative arts, manufacturing tools, etc., can solve the problems of color difference, affecting the texture of ultra-high-performance concrete handicrafts, and insufficient gloss on the surface of handicrafts. Unique, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

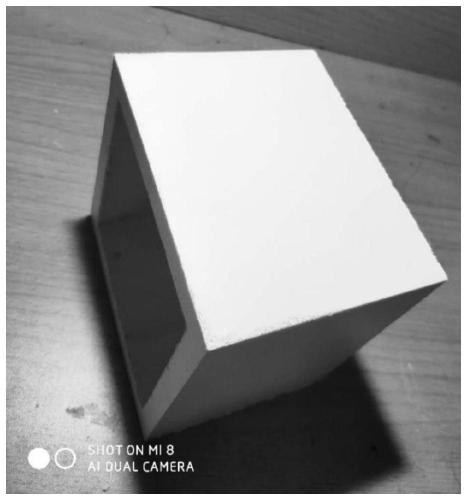

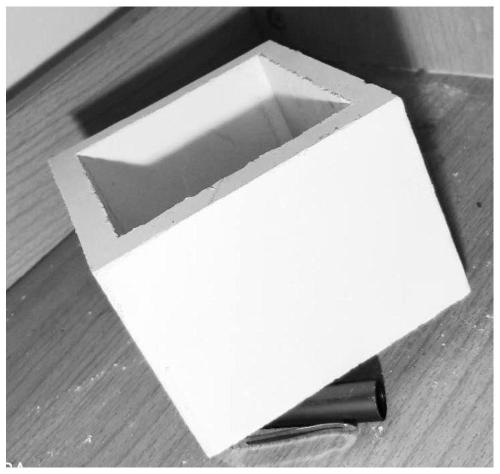

Image

Examples

Embodiment 1

[0027] A method for making concrete crafts with ceramic texture on the surface, including the following steps:

[0028] (1) Using a blow molding process to blow polyethylene plastic into the inside of a silicone mold, a layer of plastic with a thickness of 0.5 mm is formed on the inner surface of the mold to obtain a mold for molding;

[0029] (2) Stir the ultra-high performance concrete into a slurry with a fluidity of 350mm to obtain the slurry used for molding;

[0030] (3) Add the slurry used in step (2) to the mold used in step (1) for molding, leave it to stand for 6 hours after molding, and then perform dry heat curing with a mold (the time for dry heat curing is 16h, the curing temperature is 50℃), and finally the mold can be removed.

[0031] The high-performance concrete used in Example 1 is composed of cementitious material, fine quartz sand, water reducing agent, defoamer and water, the water-binder ratio is 0.16, and the amount of defoamer is 0.2% of the mass of the cemen...

Embodiment 2

[0035] A method for making concrete crafts with ceramic texture on the surface, including the following steps:

[0036] (1) Use the blow molding process to blow polypropylene plastic into the gypsum mold to form a layer of plastic with a thickness of 0.3 mm on the inner surface of the mold to obtain a mold for molding;

[0037] (2) Stir the ultra-high performance concrete into a slurry with a fluidity of 370mm to obtain the slurry used for molding;

[0038] (3) Add the slurry used in step (2) to the mold used in step (1) for molding, leave it to stand for 8 hours after molding, and then perform dry heat curing with a mold (the time for dry heat curing is 24h, the curing temperature is 40℃), and finally the mold can be removed.

[0039] The high-performance concrete used in Example 2 is composed of cementitious material, fine quartz sand, water reducing agent, defoamer and water, the water-binder ratio is 0.20, and the amount of defoamer is 0.05% of the mass of the cementitious materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com