Modified laminated paper and manufacturing method thereof

A manufacturing method and technology of coated paper, applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of low rigidity, high production cost, poor thermal stability of paper surface film, etc., achieve rigidity improvement, reduce production difficulty, The effect of improving the quality of coated paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical features and practical effects of the present invention in more detail, the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as Figure 1-2 As shown, the modified coated paper is a double-layer layered structure composed of a modified PE film 2 and a base paper 1, and the modified PE film 2 is attached to the surface of the base paper 1.

[0030] The PE material is composed of low-density polyethylene and low-density linear polyethylene in a ratio of 1:1. The modified PE film 2 is formed by mixing and extruding a nano-calcium carbonate modified powder and PE particles. The ratio of the nano-calcium carbonate modified powder and PE particles is 12:88, and the modified PE coating amount is 12-25g / m 2 .

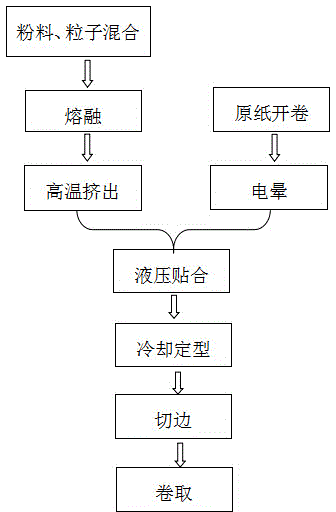

[0031] A modified coated paper and a manufacturing method thereof, comprising the following steps: raw material mixing and melting—base paper unwinding—corona—high tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com