Whole-flow multi-barrier control system and method for aldehyde halide disinfection byproducts in drinking water

A disinfection by-product, full-process technology, applied in water treatment parameter control, water/sewage multi-stage treatment, water pollutants, etc., can solve the problems of lack of full-process multi-stage barrier control strategy, dispersion, and lack of systematicness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

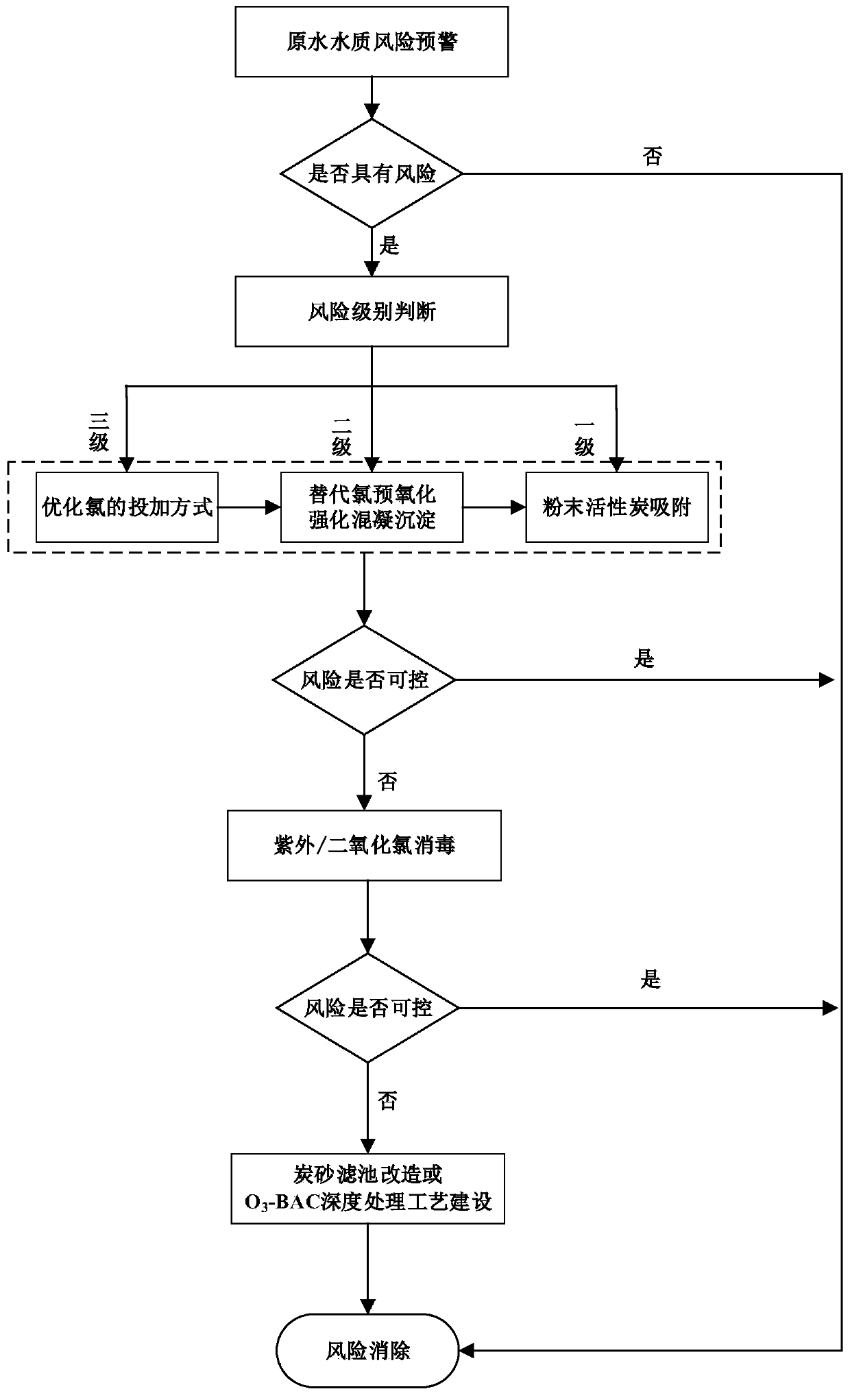

[0043] A control system for realizing the aforementioned technical scheme, the integrated control flow chart is as follows figure 1 Shown:

[0044] The control system includes in turn:

[0045] (1) Risk early warning and risk level judgment module of disinfection by-products in raw water quality;

[0046] (2) One or a combination of disinfection by-product source reduction unit, generation suppression unit, and post-generation removal unit; preferably, the source reduction unit, generation suppression unit, and post-generation removal unit are connected in sequence.

[0047] (3) One or a combination of ultraviolet irradiation treatment unit or chlorine dioxide disinfection treatment unit;

[0048] (4) carbon sand filter unit, ozone-biological activated carbon (O 3 - one or a combination of BAC) depth processing units.

[0049] The specific implementation process is as follows: (1) Judging the risk level of disinfection by-products according to the early warning method of r...

Embodiment 2

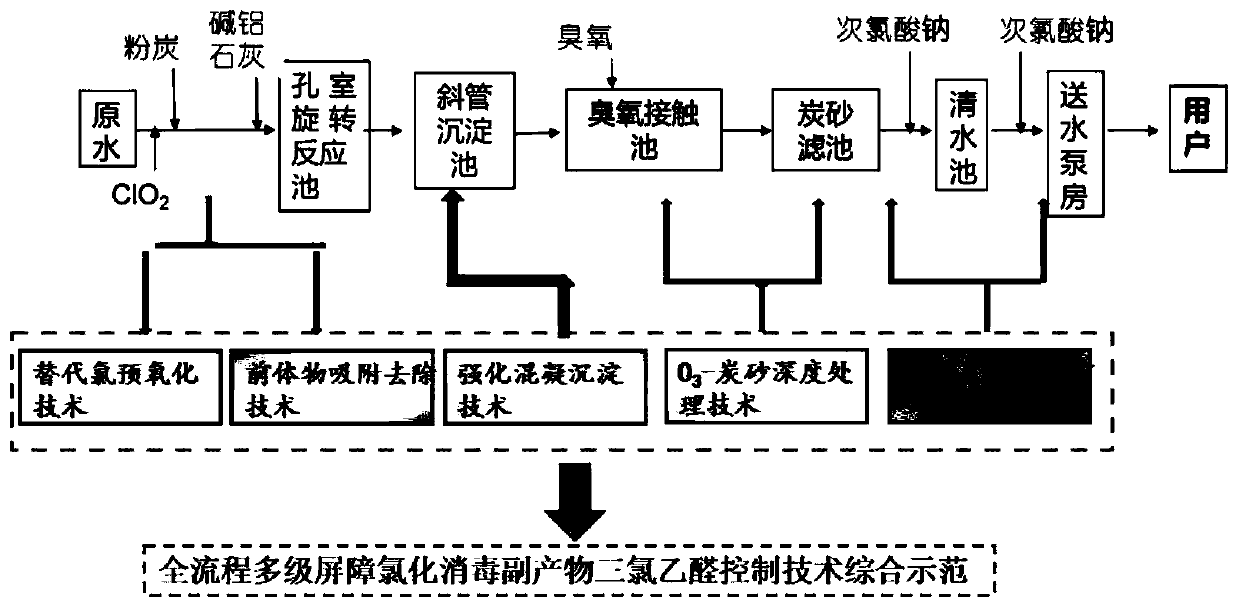

[0051] A kind of realization scheme of the present invention, control flow chart sees figure 2 shown. The water plant uses Dongjiang water as the water source (surface class III water body), and the treatment process is coagulation, sedimentation, V-shaped filter tank filtration, compound chlorine dioxide or sodium hypochlorite as pre-oxidant, and sodium hypochlorite as the main disinfection. At present, sodium hypochlorite is used for disinfection, which has problems of poor sterilization effect and excessive risk of by-products such as chloral.

[0052] Relying on the upgrade and renovation project of the water plant, adjust and optimize the pre-oxidation method to inhibit the formation of chloral; strengthen and transform the conventional process, build advanced treatment facilities, optimize the removal of by-products and their precursors; optimize the disinfection method to reduce the formation of by-products ; When the water quality deteriorates, take emergency control...

Embodiment 3

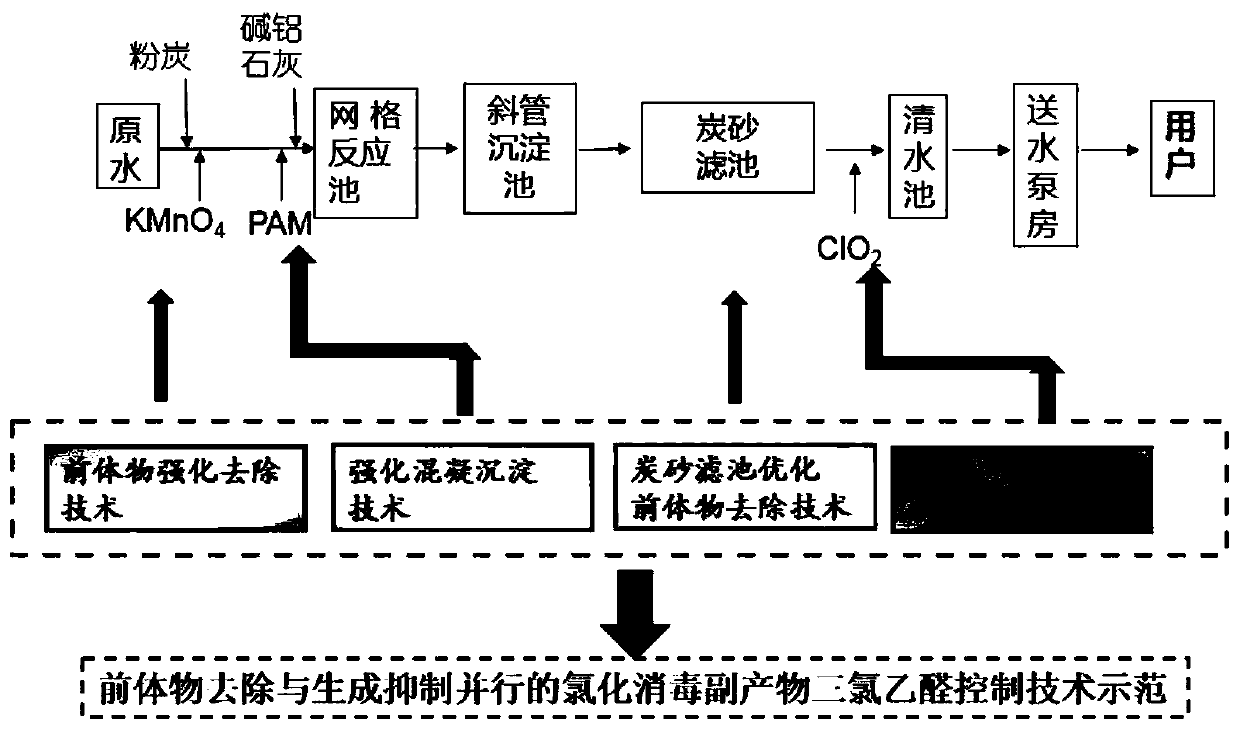

[0061] A kind of realization scheme of the present invention, control flow chart sees image 3 shown. The design scale of the water plant is 35,000 m 3 / d, the raw water comes from the river, and is treated by conventional processes such as grid reaction tanks, inclined tube sedimentation tanks, and siphon filters. Pre-oxidation with high-purity chlorine dioxide and main disinfection with sodium hypochlorite. The city where the city is located has a subtropical climate in the south, with high temperature and rain all year round, and there are breeding areas in the upper reaches of the river. The raw water in the rainy season is seriously polluted by non-point sources, and there is a phenomenon of high short-term organic matter concentration. The processing effect is limited. The organic matter in the water body reacts with the disinfectant sodium hypochlorite to produce a variety of disinfection by-products, among which the problem of chloral is the most prominent, and effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com