Ultraviolet, visible and near-infrared light absorbing glass as well as preparation method and application thereof

A near-infrared light and glass technology, applied in glass manufacturing equipment, glass furnace equipment, glass molding, etc., can solve problems affecting imaging quality, increasing fiber loss, etc., and achieve satisfactory thermal performance and good composition stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0035] The materials and reagents used in the following examples can all be obtained from commercial sources.

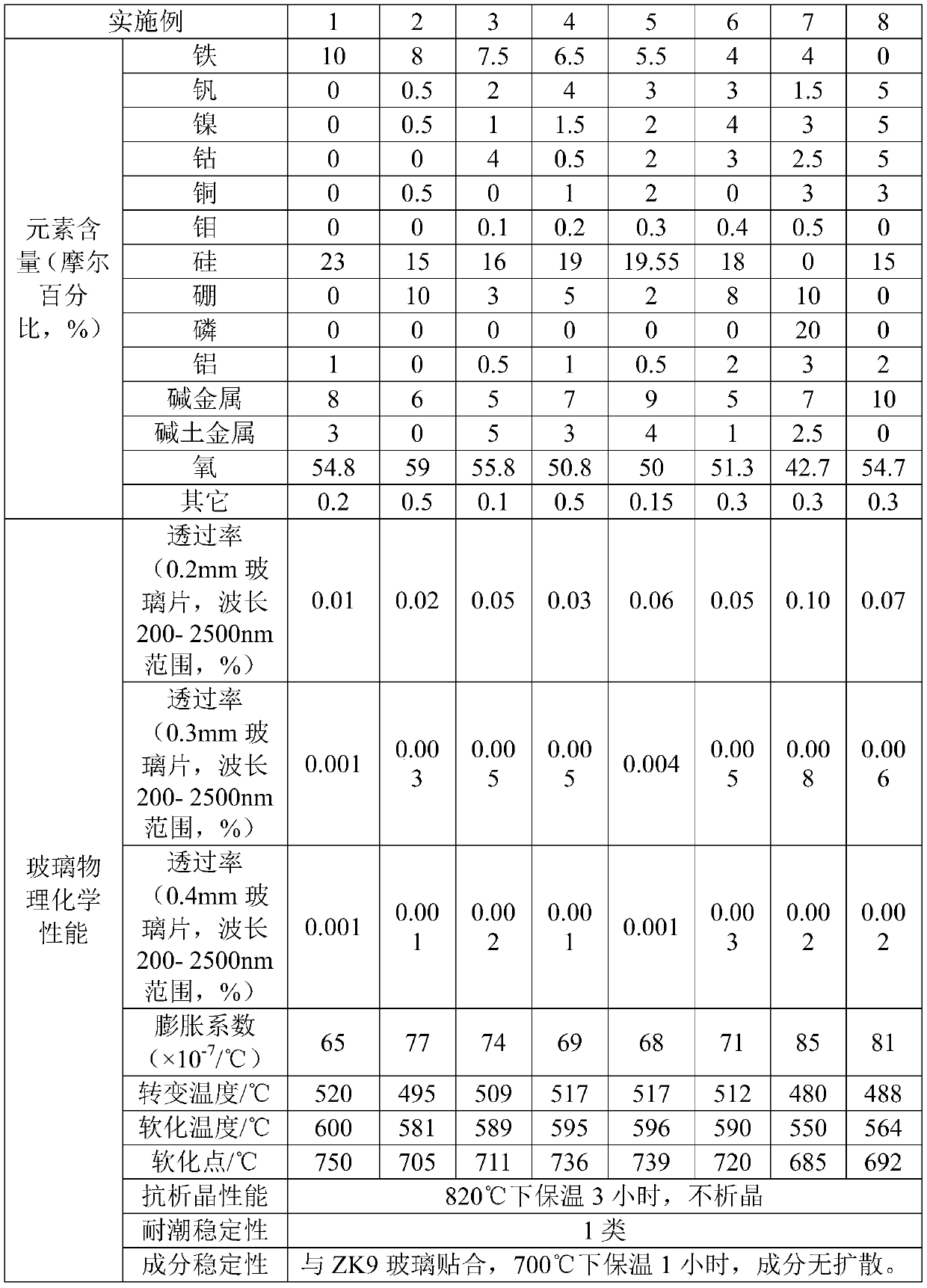

[0036] Table 1 shows the composition and physical and chemical properties of the ultraviolet, visible and near-infrared light-absorbing glasses of Examples 1-8 of the present invention.

[0037] Among them, the refractive index is tested according to GB / T 7962.1-2010; the expansion coefficient, transition temperature, softening temperature, and softening point are tested according to GB / T 7962.16-2010; the transmittance is tested according to GB / T 7962.12-2010; the moisture resistance stability is tested according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com