A kind of copper-containing two-component composite antibacterial fiber and its preparation method

A compound antibacterial, two-component technology, applied in the direction of fiber treatment, fiber chemical characteristics, single-component polyester artificial filament, etc., can solve the problems of poor spinnability and color, achieve strong antibacterial ability, weaken copper Antibacterial color, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

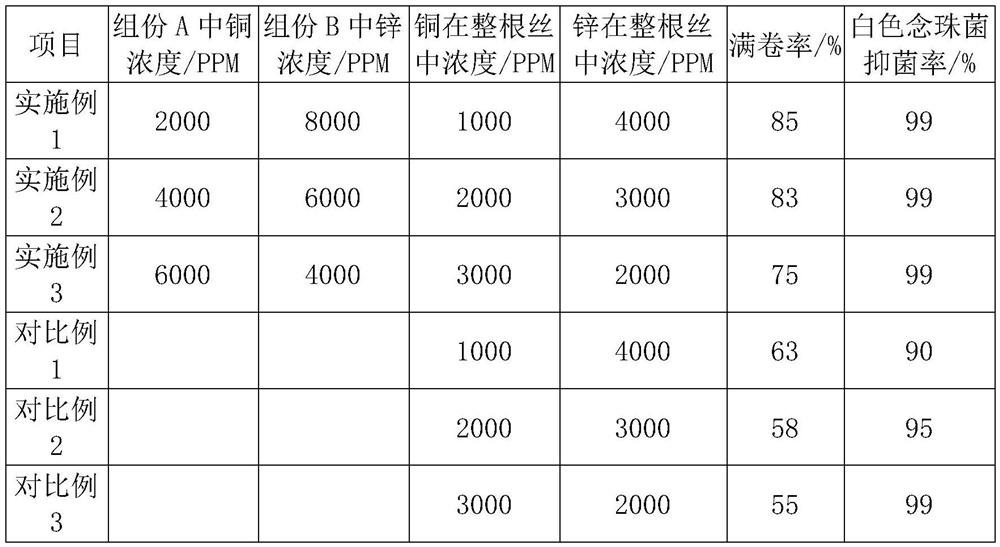

Embodiment 1

[0027] (1) Component A is composed of low-viscosity polyethylene terephthalate and nano-copper. The intrinsic viscosity of low-viscosity PET is 0.5dl / g, and the average particle size of elemental copper is 0.3u. The proportion is 0.2%.

[0028] Component B is composed of high-viscosity polybutylene terephthalate and nano-zinc oxide. The intrinsic viscosity of high-viscosity PBT is 1.1dl / g. Nano-zinc oxide is rod-shaped active zinc oxide. The mass proportion in component B is 0.8%.

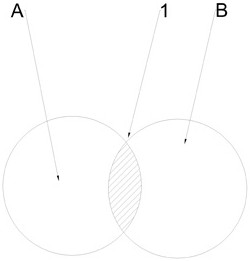

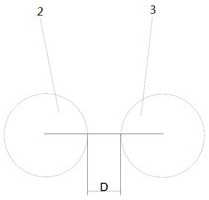

[0029] (2) Two-component composite spinning equipment is used: component A and component B are mixed uniformly in a mass ratio of 1:1, melted by a screw, and then the spinning of component A and component B is carried out by a metering pump. The melt is transported to the spinning assembly, and simultaneously passes through a distribution system and a spinneret that can prepare a side-by-side structure. The distance between the spinneret hole 2 of component A and the spinneret hole 3 of component ...

Embodiment 2

[0033] (1) Component A is composed of low-viscosity polyethylene terephthalate and nano-copper. The intrinsic viscosity of low-viscosity PET is 0.53dl / g, and the average particle size of elemental copper is 0.4u. The proportion is 0.4%.

[0034] Component B is composed of high-viscosity polybutylene terephthalate and nano-zinc oxide. The intrinsic viscosity of high-viscosity PBT is 1.2dl / g. Nano-zinc oxide is rod-shaped active zinc oxide. The mass proportion in component B is 0.6%.

[0035] (2) The production process is the same as in Example 1 step (2), wherein the distance between the spinneret hole 2 of component A and the spinneret hole 3 of component B is D, and D=0.12mm, such as figure 2 As shown, a copper-containing two-component composite antibacterial fiber b was prepared.

[0036] Among them, the spinning temperature of component A is 275°C, the spinning temperature of component B is 270°C, the draft ratio is 2.7, the setting temperature is 120°C, and the winding ...

Embodiment 3

[0039] (1) Component A is composed of low-viscosity polyethylene terephthalate and nano-copper. The intrinsic viscosity of low-viscosity PET is 0.56dl / g, and the average particle size of elemental copper is 0.6u. Its mass in component A The proportion is 0.7%.

[0040] Component B is composed of high-viscosity polybutylene terephthalate and nano-zinc oxide. The intrinsic viscosity of high-viscosity PBT is 1.3dl / g. Nano-zinc oxide is rod-shaped active zinc oxide. The mass proportion in component B is 0.4%.

[0041] (2) The production process is the same as the step (2) of Example 1, wherein the distance between the spinneret hole 2 of component A and the spinneret hole 3 of component B is D, and D=0.07mm, such as figure 2 As shown, a copper-containing two-component composite antibacterial fiber c was prepared.

[0042] Among them, the spinning temperature of component A is 276°C, the spinning temperature of component B is 272°C, the draft ratio is 2.4, the setting temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com