Multi-layered heating device for heating bituminous pavement milling material

A technology of asphalt pavement and heating device, which is applied to roads, roads, road repair and other directions, can solve the problems of high temperature of asphalt mixture, affect the performance of asphalt, and consume large fuel, so as to improve the temperature of roadbed, save fuel, and improve heating. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

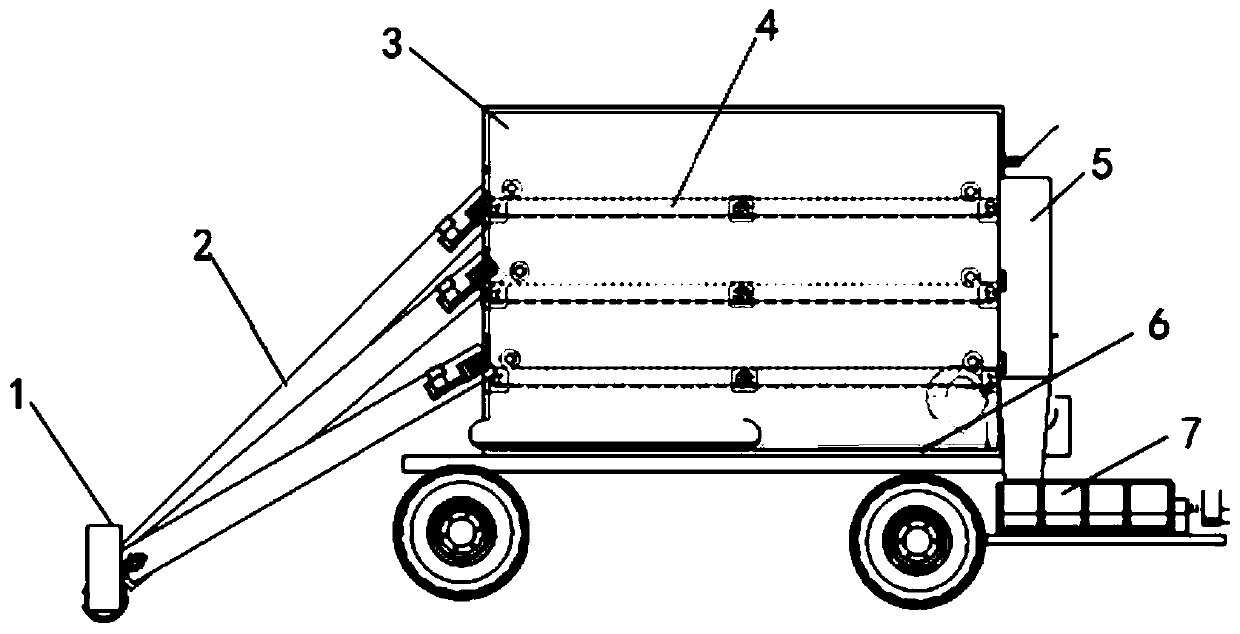

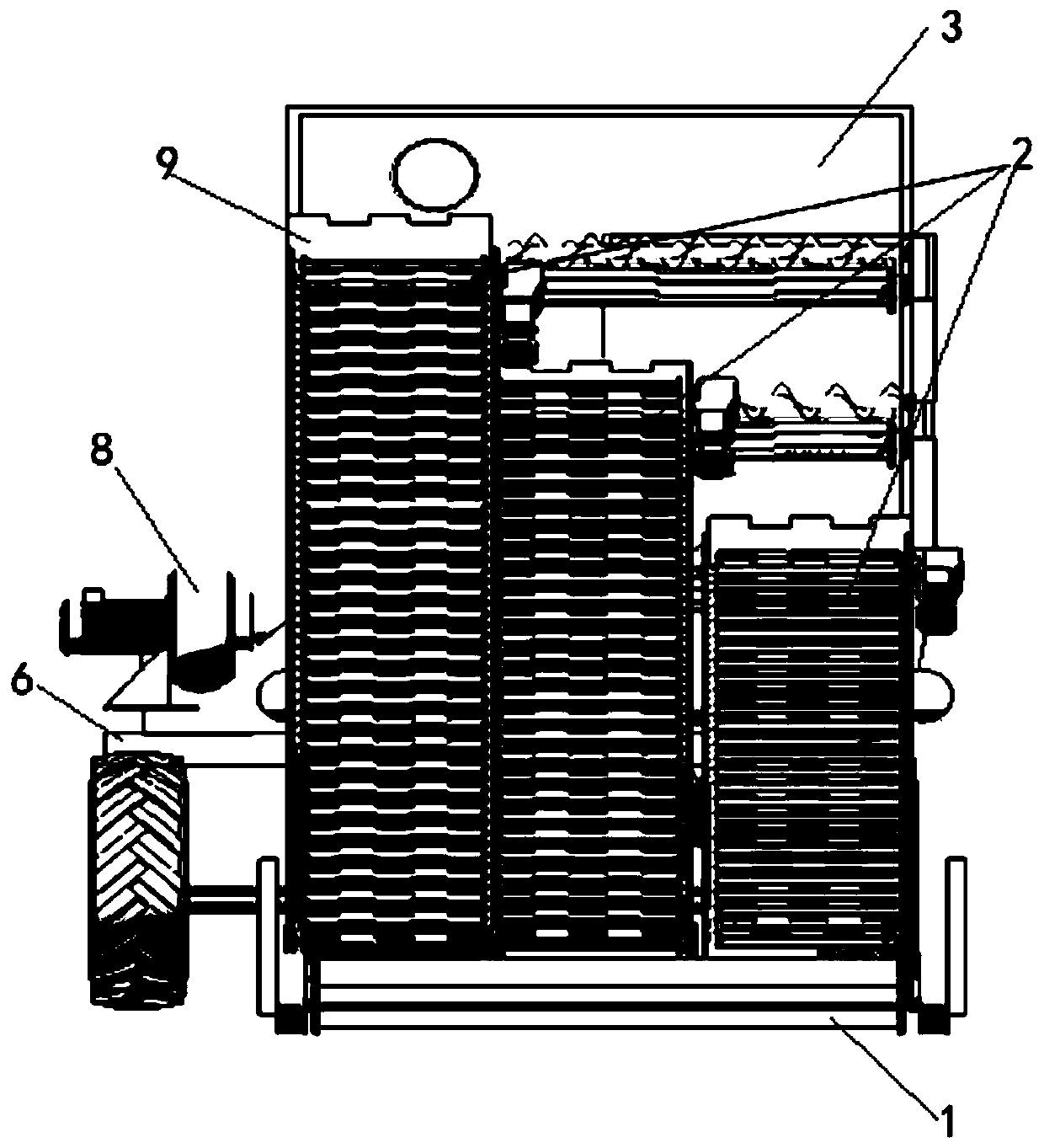

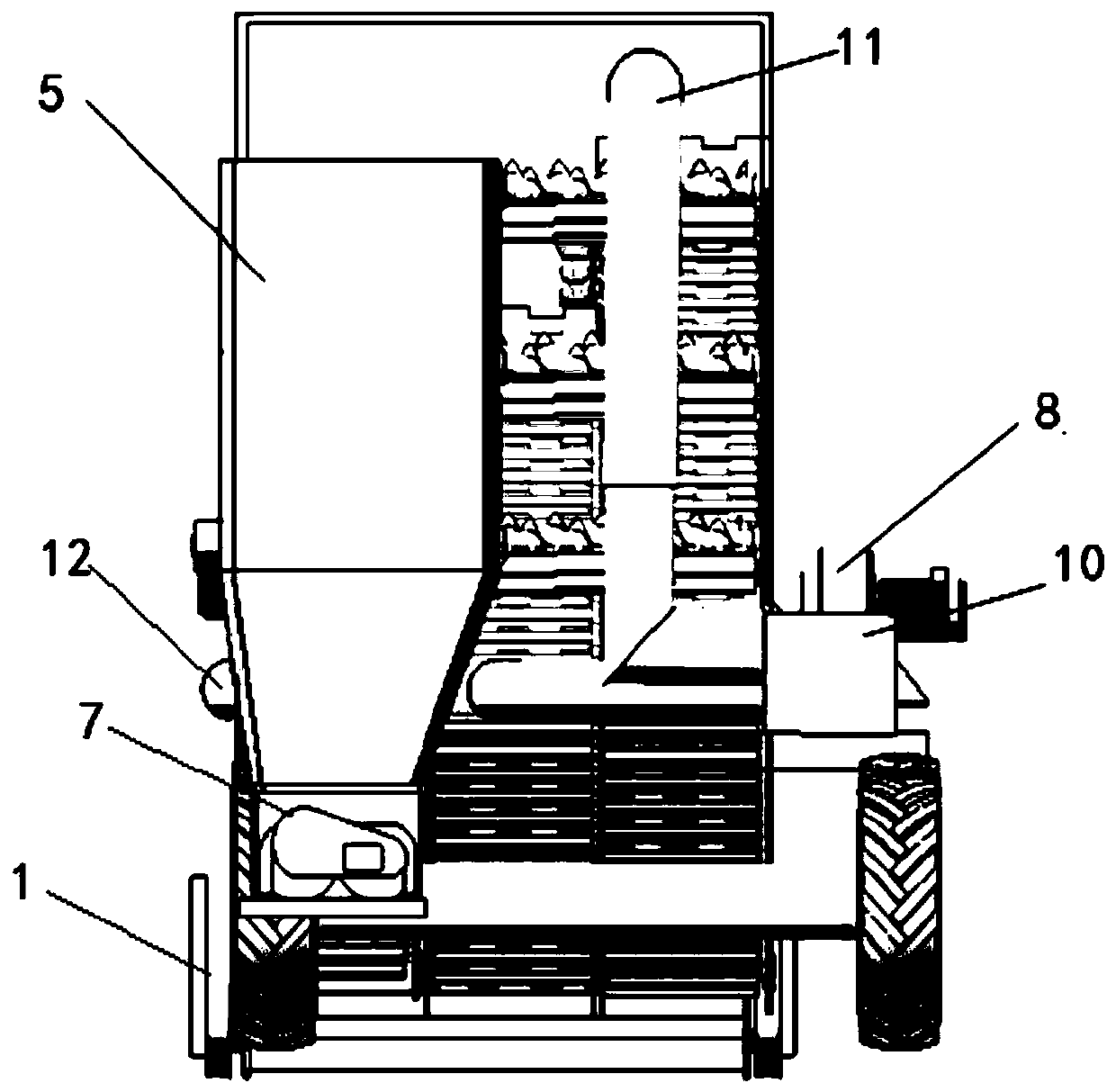

[0032] In the hot-in-place regeneration process, the road surface is first heated continuously by the road surface heating machine, and then the asphalt pavement is thermally milled by the road surface milling vehicle, and the old road surface is heated and milled to form a trapezoidal ridge of asphalt mixture. In the present invention, the scraper feeder 1 is suspended below the rear end of the milling machine, and the frame of the device is dragged and hung on the rear end of the milling machine simultaneously. The material ridge produced after the milling machine works is transmitted to a plurality of scraper elevators 2 through the scraper feeder 1, and these scraper elevators 2 are respectively transported to each layer of conveying device 4 through the feed port 9; The conveying device 4 on the first floor is under the action of the first driving device, and the chain plate 403 on it conveys the asphalt mixture to the discharge port 13 at the rear. When the screw distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com